Device and method for measuring hydrogen diffusion coefficient

A diffusion coefficient and testing system technology, applied in the direction of material electrochemical variables, etc., can solve problems such as complex device design, incomplete oxygen removal, and inaccurate measurement results, so as to improve accuracy and reliability, facilitate device construction, and test Effects in simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

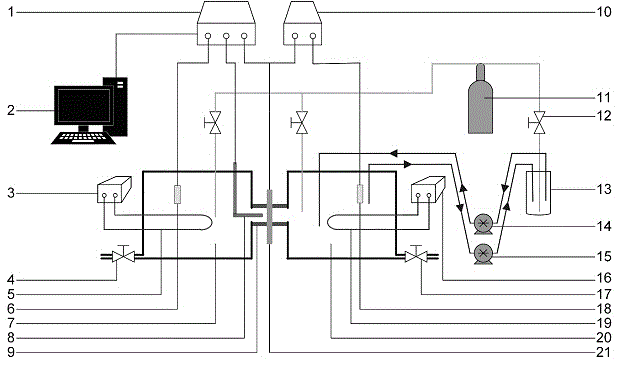

[0036] In this example, see figure 1 and figure 2 , a device for measuring the hydrogen diffusion coefficient, consisting of a hydrogen diffusion test system, a temperature control system, and an oxygen removal system. The hydrogen diffusion test system consists of an electrochemical workstation 1, a computer or recorder 2, an anode cell drain valve 4, and an anode cell Auxiliary electrode 6, anode cell 7, reference electrode 8, connection gasket 9, DC constant current source 10, cathode cell drain valve 17, cathode cell auxiliary electrode 18, cathode cell 20 and sample to be tested 21, anode cell 7 and the cavity of the cathode pool 20 are made of glass, the auxiliary electrode 6 of the anode pool and the auxiliary electrode 18 of the cathode pool are made of platinum sheet electrodes, the connecting gasket 9 is made of fluororubber gasket, the current measurement range of the electrochemical workstation 1 is 0~±2A, and the current measurement The accuracy is ±10pA, the ou...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, especially in that:

[0045] In this example, see image 3 , the device for measuring the hydrogen diffusion coefficient, the cavity of the anode pool 7 and the cathode pool 20 is made of polytetrafluoroethylene. The anode cell auxiliary electrode 6 and the cathode cell auxiliary electrode 18 adopt nickel electrodes. The nitrogen pipeline used in the oxygen removal system adopts fluorine rubber tube. Delivery pump 14 and reflux pump 15 adopt miniature alkaline pumps. Connecting washer 9 adopts silica gel washer. The area of the test sample 21 exposed to the solution is 4cm 2 . The current measurement range of electrochemical workstation 1 is 0~±2A, the current measurement accuracy is ±10pA, the output range is ±10V, and the accuracy is ±0.1mV. The current output range of the DC constant current source 10 is 0~±200mA, and the control accuracy is ±1nA. The quantity of deoxygenating bottle 13 is 3.

[0046] I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal power | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com