Optical film, polarizing plate, and method for producing optical film

一种光学膜、偏振片的技术,应用在光学膜领域,能够解决着色等问题,达到着色问题减少、制造工序高效化、对比度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0316]

[0317] As the support, a commercially available triacetyl cellulose film "Z-TAC" (manufactured by Fujifilm Corporation) was used. Pass it through a dielectric heating roll support whose temperature is adjusted to 60°C, raise the film surface temperature of the support to 40°C, and then apply a coating amount of 14ml / m on one side of the film using a bar coater 2 An alkali solution having the composition shown below was applied and heated to 110°C. Thereafter, the support was conveyed for 10 seconds under a vapor-type far-infrared heater manufactured by NORITAKE CO., LIMITED. Next, use the same bar coater to coat the surface coated with the alkali solution at 3ml / m 2 Apply pure water. Next, water washing with a jet coater and water removal with an air knife were repeated three times, and then transported in a drying zone at 70°C for 10 seconds and dried to prepare a transparent support treated with alkali saponification. .

[0318]

[0319]

[0320]

[03...

Embodiment 1-2

[0348]

[0349] Alkaline saponification treatment was performed on the surface of the support of the cellulose triacetate film TD80UL (manufactured by Fujifilm). Specifically, the support was immersed in a 1.5N aqueous sodium hydroxide solution at 55°C for 2 minutes, washed in a water bath at room temperature, and neutralized at 30°C with 0.1N sulfuric acid. After washing again in a water bath at room temperature, it was further dried with warm air at 100°C.

[0350] A roll-shaped polyvinyl alcohol film with a thickness of 80 μm was continuously stretched 5 times in the MD direction in an iodine aqueous solution in the same manner as in Example 1-1, and dried to obtain a polarizing film with a thickness of 20 μm.

[0351] By sticking the positive C-plate side of the optical film 1 made above on one side of the above-mentioned polarizing film, and further sticking the above-mentioned cellulose triacetate film through alkali saponification treatment on the other side of the po...

Embodiment 2

[0353]

[0354] The following positive coating liquid 2 for plate A was prepared.

[0355]

[0356] [chem 28]

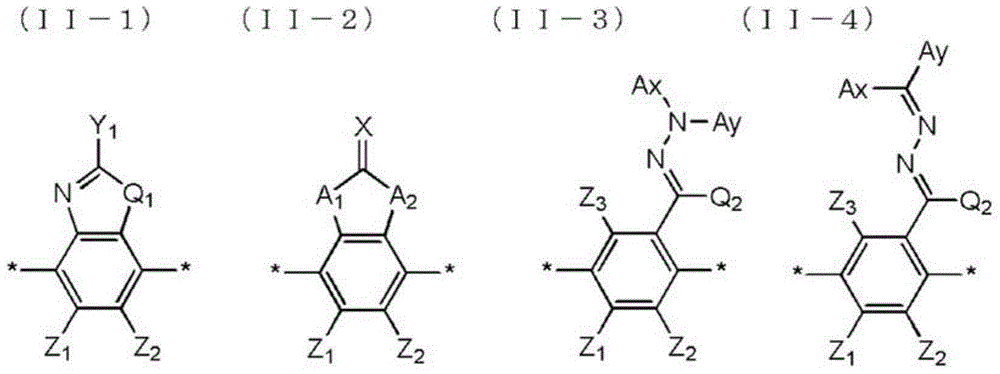

[0357] Reverse wavelength dispersion liquid crystal compound R-2: specific example II-2-2

[0358]

[0359] Cross-linked polymer O-2

[0360]

[0361] However, Tg=10 degreeC of crosslinkable polymer O-2.

[0362]A triacetyl cellulose film having an alignment film 1 on its surface was produced in the same procedure as in Example 1-1, and the alignment film 1 was rubbed. The positive A-plate A-0 forming coating liquid 2 was coated on the friction-treated surface using a bar coater. Next, heat curing was carried out at a film surface temperature of 150°C for 60 seconds, cooled to 70°C, and then irradiated at 1000mJ / cm in the atmosphere using an air-cooled metal halide lamp (manufactured by Eye Graphics Co., Ltd.). 2 The ultraviolet rays fix its orientation state to form a positive A-plate A-0(2). The direction of the slow axis of the formed positive A pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com