Method for accurately controlling temperature and pressure of supercritical extraction process

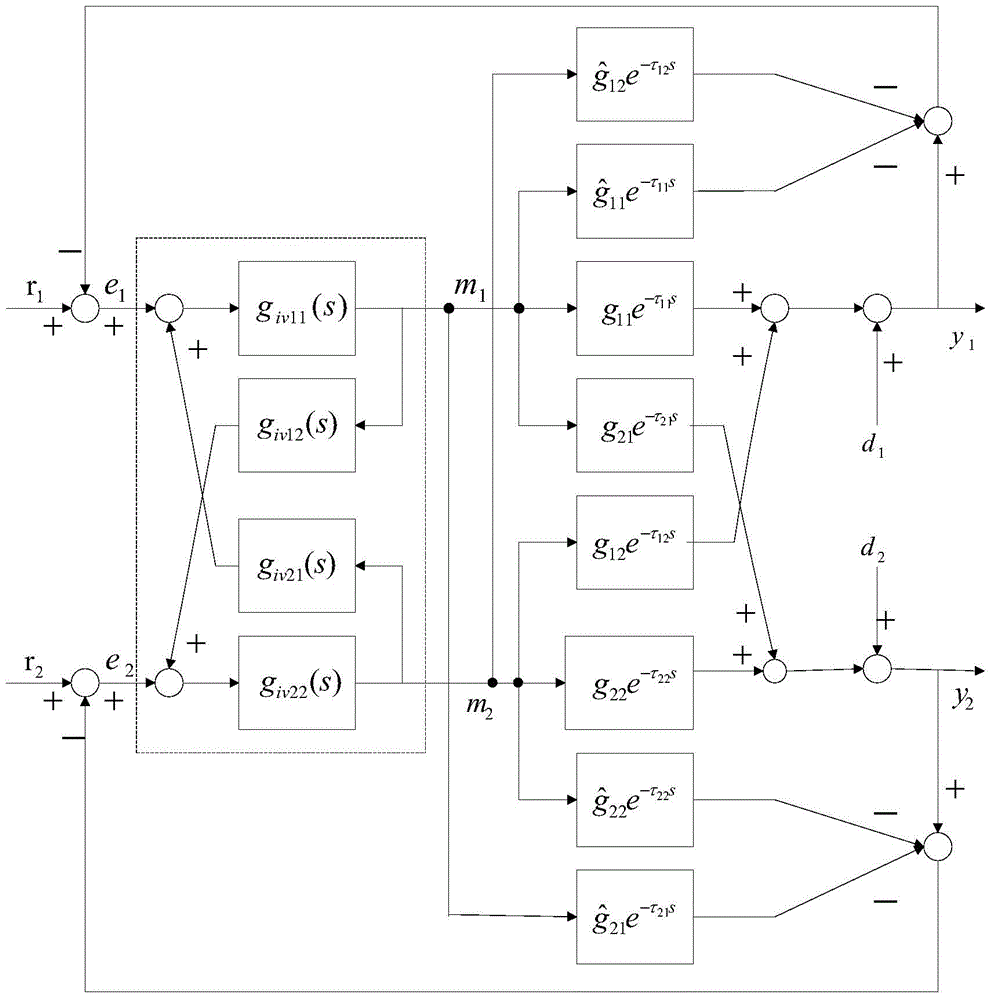

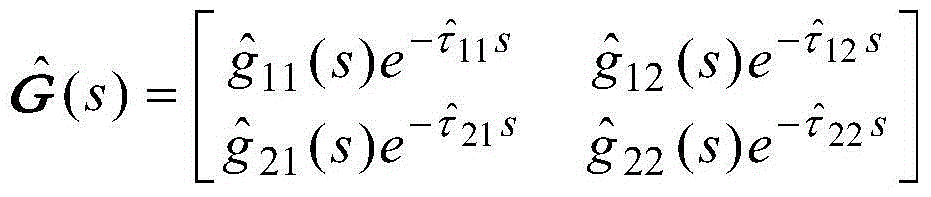

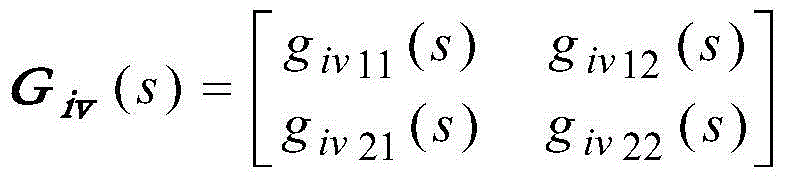

A supercritical and pressure technology, applied in the direction of non-electric variable control, control/regulation system, simultaneous control of multiple variables, etc., can solve the problems of supercritical fluid density reduction, extraction volume increase, disturbance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The method of the present invention is:

[0034] (1) To control the temperature and pressure of the extraction axe, it must first be extracted accurately. According to the process requirements, the sensor for measuring the temperature in the extraction kettle is installed in the jacket of the hot water circulating in the extraction axe; the sensor for measuring the pressure in the extraction kettle is installed in the pipeline where the supercritical carbon dioxide fluid enters the inlet of the extraction kettle.

[0035] (2) The heat required for the temperature rise and fall in the extraction ax is provided by the circulating hot water in the jacket of the extraction kettle, and the circulating hot water is heated by the electric heating tube in the hot water tank, and then supplied to the extraction kettle by a thermal circulation pump The hot water in the jacket is circulated, and the heating tube is controlled on and off by a solid state relay. According to the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com