Manufacturing method of large-diameter multi-core combined core rod

A production method and a large-diameter technology, which is applied in the direction of electrical components, insulators, circuits, etc., can solve the problems of increased diameter and size of composite insulator mandrels, difficulty in making large-diameter mandrels, etc., and achieve technical stability, feasibility and repeatability Strong, simple production process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

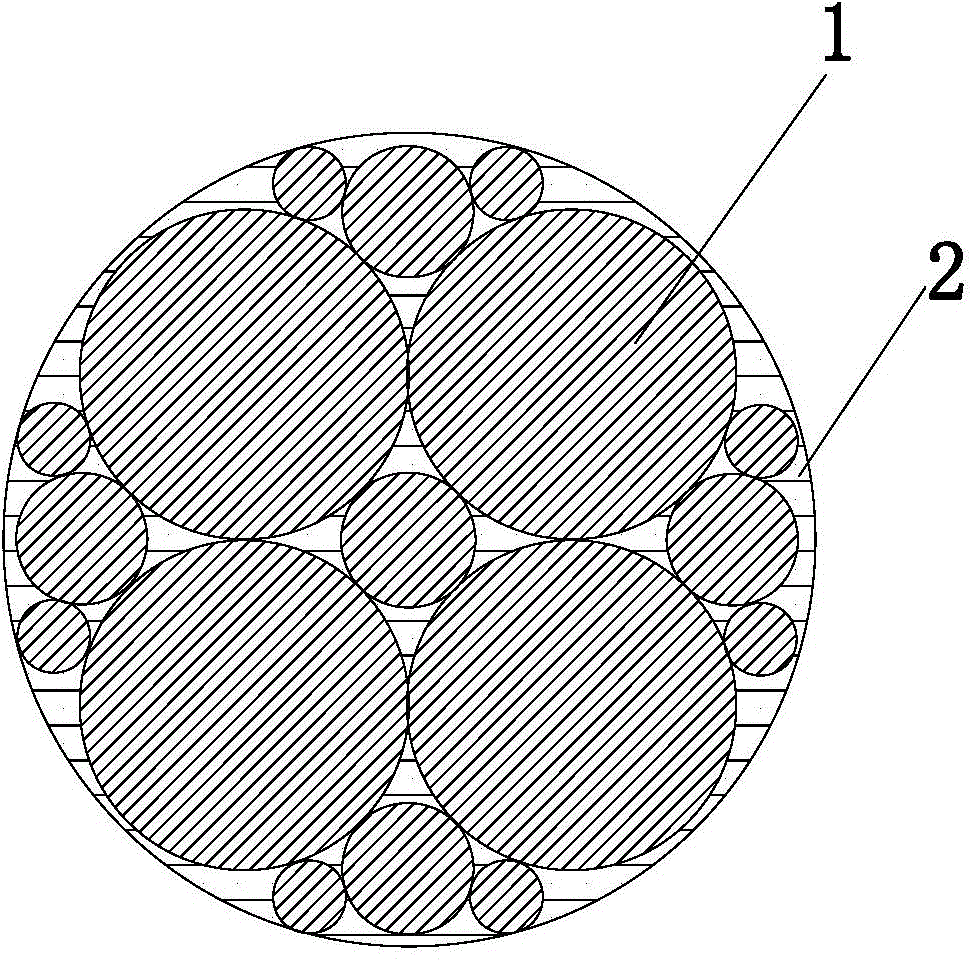

[0037] The large-diameter multi-core combined mandrel to be produced in this embodiment is a cylindrical structure with a cross-sectional diameter of 180 mm; the manufacturing method of the large-diameter multi-core combined mandrel in this embodiment comprises the following steps:

[0038] Step 1. According to the design requirements of the large-diameter multi-core combined mandrel to be made, select the single-core mandrel 1 made of glass fiber reinforced epoxy resin. The single-core mandrel 1 selected in this embodiment is respectively: specifications 4 single-core mandrels with a diameter of Ф74.5mm, 5 single-core mandrels with a specification of Ф30.5mm, and 8 single-core mandrels with a specification of Ф15mm; then the selected single-core mandrel 1 is pretreated, The specific process is:

[0039] Step 101, sandblasting the selected single-core mandrel 1;

[0040] Step 102. Wipe the single-core mandrel 1 after sandblasting in step 101 with a rag dipped in alcohol, and ...

Embodiment 2

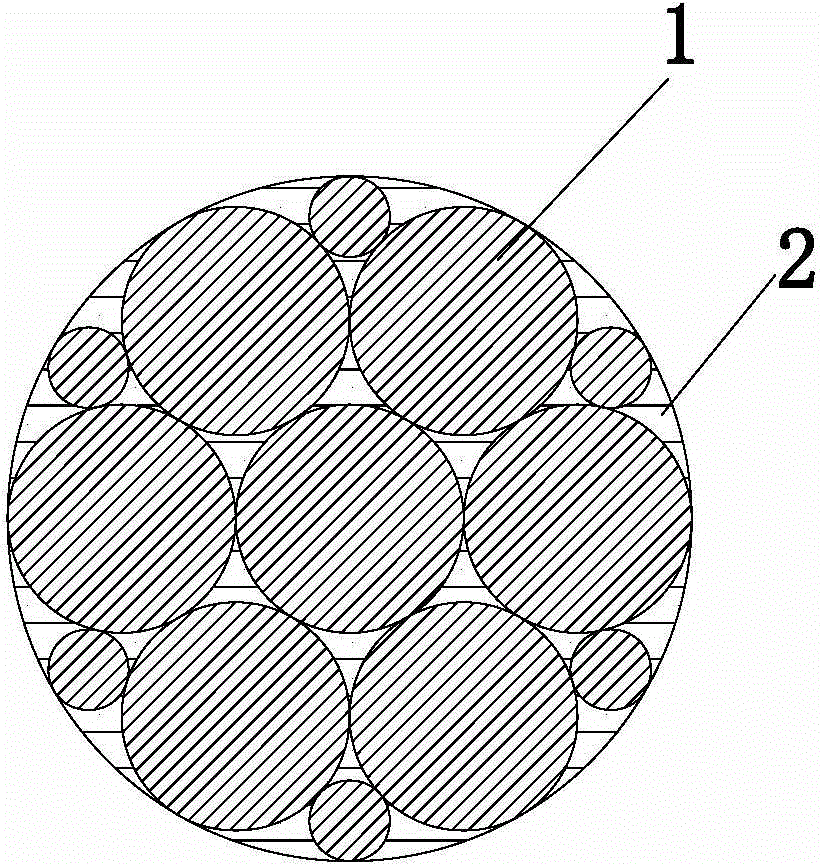

[0050] The large-diameter multi-core combined mandrel to be produced in this embodiment is a cylindrical structure with a cross-sectional diameter of 170mm; the manufacturing method of the large-diameter multi-core combined mandrel in this embodiment includes the following steps:

[0051] Step 1. According to the design requirements of the large-diameter multi-core combined mandrel to be made, select the single-core mandrel 1 made of glass fiber reinforced epoxy resin. The single-core mandrel 1 selected in this embodiment is respectively: specifications 4 single-core mandrels with a diameter of Ф70mm, 5 single-core mandrels with a specification of Ф28.5mm, and 8 single-core mandrels with a specification of Ф14mm; for:

[0052] Step 101, sandblasting the selected single-core mandrel 1;

[0053] Step 102. Wipe the single-core mandrel 1 after sandblasting in step 101 with a rag dipped in alcohol, and then dry it in a drying oven at 80°C for 1 hour;

[0054] Step 103, evenly sme...

Embodiment 3

[0063] The large-diameter multi-core combined mandrel to be produced in this embodiment is a cylindrical structure with a cross-sectional diameter of 210mm; the manufacturing method of the large-diameter multi-core combined mandrel in this embodiment includes the following steps:

[0064] Step 1. According to the design requirements of the large-diameter multi-core combined mandrel to be made, select the single-core mandrel 1 made of glass fiber reinforced epoxy resin. The single-core mandrel 1 selected in this embodiment is respectively: specifications 4 single-core mandrels with a diameter of Ф86mm, 5 single-core mandrels with a specification of Ф35mm, and 8 single-core mandrels with a specification of Ф17.5mm; for:

[0065] Step 101, sandblasting the selected single-core mandrel 1;

[0066] Step 102. Wipe the single-core mandrel 1 after the sandblasting treatment in step 101 with a rag dipped in alcohol, and then place it in a drying oven at a temperature of 60° C. for 1 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com