Brushless direct-current motor regenerative braking system adopting single-current sensor

A brushed DC motor and regenerative braking technology, applied in the direction of electronic commutation motor control, control system, electrical components, etc., can solve the problems of recovering braking energy, reducing feedback current, and inability to directly and effectively control, and achieve low cost. , Taking into account the energy feedback effect and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

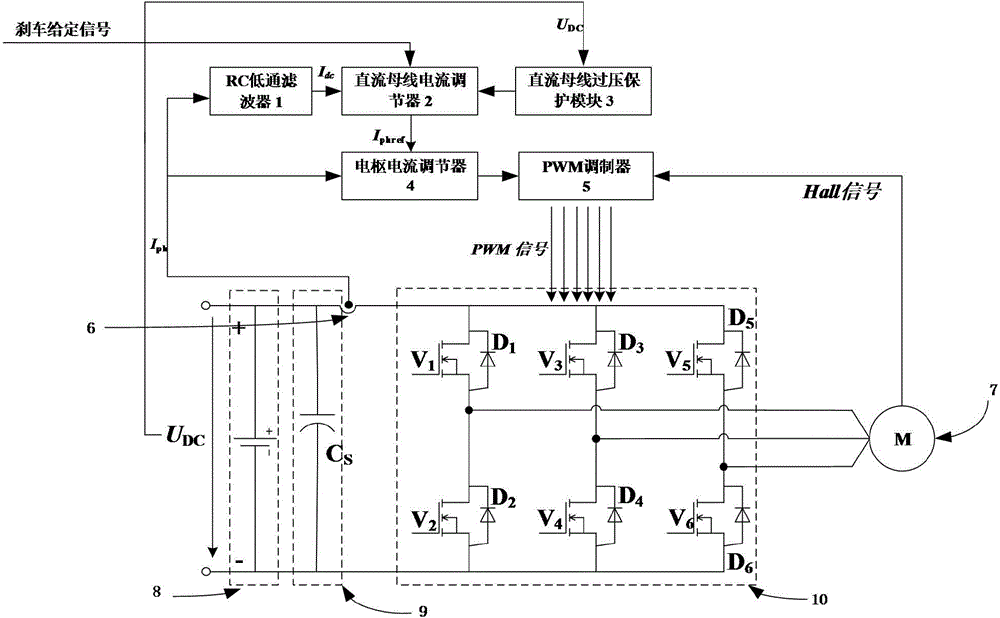

[0022] Such as Figure 1-3 As shown, a brushless DC motor feedback braking system using a single current sensor includes an RC low-pass filter 1, a DC bus current regulator 2, a DC bus overvoltage protection module 3, and an armature current regulator 4 , PWM modulator 5, bus current sensor 6, permanent magnet brushless DC motor 7, battery 8, bus capacitor 9, three-phase full-bridge inverter 10.

[0023] The three-phase windings of the permanent magnet brushless DC motor 7 are connected to the three half-bridge arms of the three-phase full-bridge inverter 10; the three-phase full-bridge inverter 10 is connected in parallel with the positive and negative buses of the bus capacitor 9 and the battery 8 ; The bus current sensor 6 is placed on the positive bus or the negative bus to detect the bus current flowing in the three-phase full-bridge inverter 10; the input of the DC bus overvoltage protection module 3 is the bus voltage signal U DC , Its output to the DC bus current regulator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com