A waterproof foam stabilizer with adjustable setting time and preparation method thereof

A technology of coagulation time and foam stabilizer, which is applied in the field of waterproof foam stabilizer and its preparation, can solve the problems of increasing the complexity of the production process, reducing the compactness of the product, and reducing the strength of the product, so as to shorten the demoulding and curing time, increase the Production efficiency and the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

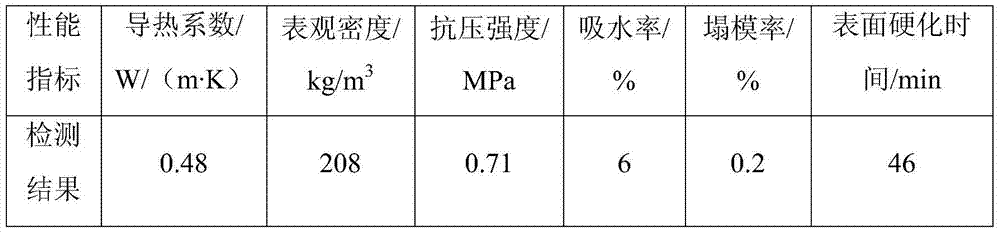

Embodiment 1

[0026] When the production environment temperature of cement foam insulation board is 30°C:

[0027] A waterproof and foam stabilizer with adjustable setting time, the addition amount of each raw material is: 45kg of stearic acid, 8kg of potassium hydroxide, 3kg of soda ash, 28kg of ammonia water (mass concentration is 20%), 60g of sodium fluoride, triethanolamine 7kg, sodium chloride 15kg, lithium carbonate 8kg, water 886kg, its preparation method comprises the following steps:

[0028] Put 300kg of water in a stirring container, heat to 60°C, add potassium hydroxide, soda ash, sodium fluoride, sodium chloride and lithium carbonate, stir for 1 min until completely dissolved, quickly add stearic acid, and continue stirring for 10 min until the stearic acid The acid is completely dissolved to obtain an ammonium stearate emulsion (foam-stabilizing component); then add 586kg of water, add triethanolamine when the solution is cooled to 20°C, stir for 5min, then add ammonia water, ...

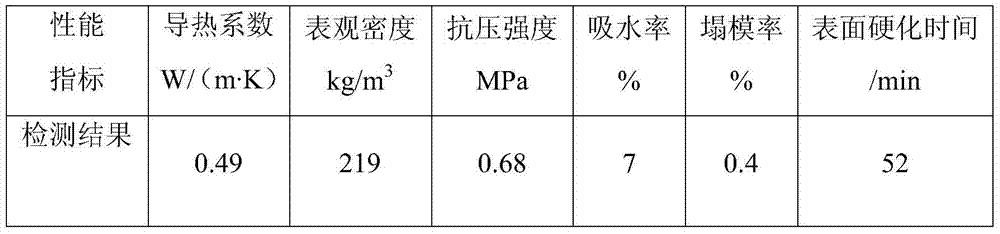

Embodiment 2

[0034] When the production environment temperature of cement foam insulation board is 20°C:

[0035] A foam cement waterproof foam stabilizer with adjustable setting time, the addition of each raw material is: stearic acid 50kg, potassium hydroxide 9kg, soda ash 3kg, ammoniacal liquor 32kg (mass concentration is 20%), sodium fluoride 60g, Triethanolamine 7kg, sodium chloride 20kg, lithium carbonate 10kg, water 869kg, its preparation method comprises the following steps:

[0036] Put 300kg of water in a stirring container, heat to 60°C, add potassium hydroxide, soda ash, sodium fluoride, sodium chloride and lithium carbonate, stir for 1 min until completely dissolved, quickly add stearic acid, and continue stirring for 10 min until the stearic acid The acid is completely dissolved to obtain an ammonium stearate emulsion (foam-stabilizing component); then add 569kg of water, add triethanolamine when the solution is cooled to 20°C, stir for 5min, then add ammonia water, continue ...

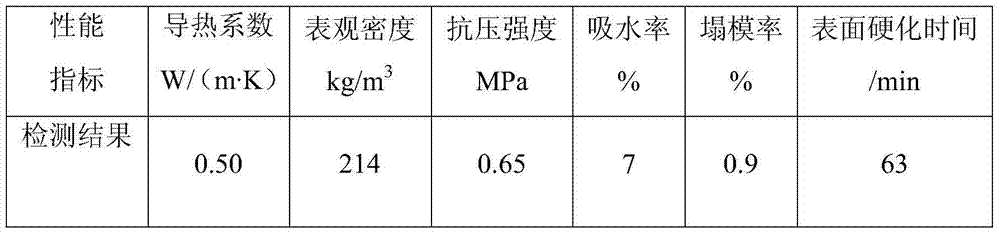

Embodiment 3

[0042] When the production environment temperature of cement foam insulation board is 10°C:

[0043] A waterproof foam stabilizer with adjustable setting time, the addition amount of each raw material is: stearic acid 55kg, potassium hydroxide 10kg, soda ash 3.5kg, ammonia water 38kg (mass concentration is 20%), sodium fluoride 60g, triethanolamine 9kg, sodium chloride 40kg, lithium carbonate 15kg, water 830kg, its preparation method comprises the following steps:

[0044] Put 300kg of water in a stirring container, heat to 60°C, add potassium hydroxide, soda ash, sodium fluoride, sodium chloride and lithium carbonate, stir for 1 min until completely dissolved, quickly add stearic acid, and continue stirring for 10 min until the stearic acid The acid is completely dissolved to obtain an ammonium stearate emulsion (foam-stabilizing component); then add 530kg of water, add triethanolamine when the solution is cooled to 20°C, stir for 5min, then add ammonia water, continue stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com