A kind of preparation method of gypsum retarder

The technology of gypsum retarder and slag is applied in the field of preparation of inorganic gypsum retarder to achieve the effects of saving resources, wide material sources and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

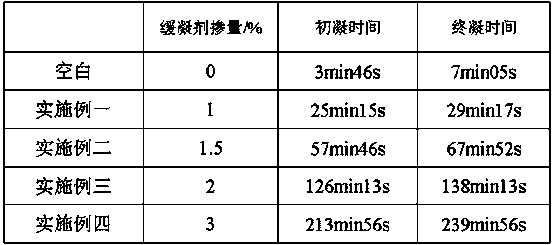

Examples

Embodiment 1

[0019] The specific surface area of slag is 394m 2 / kg; the loss on ignition of fly ash is 8.1%, and its 0.08mm square hole sieve residue is 11%; sodium hydroxide is industrial grade, with an effective content of 99%; the solid content of water glass is 27%, and the modulus is 3.5.

[0020] The ratio of materials by mass is: 60 parts of slag, 70 parts of fly ash, 10 parts of sodium hydroxide, 2 parts of water glass, and water-solid ratio of 0.30; according to the method of the present invention, the slurry is poured into shape, and the test block is at normal temperature. After curing for 28 days, dry, crush, and then grind to make gypsum retarder (its specific surface area is 428m 2 / kg).

Embodiment 2

[0022] The specific surface area of slag is 312m 2 / kg; the loss on ignition of fly ash is 4.3%, and its 0.08mm square hole sieve residue is 14%; sodium hydroxide is industrial grade, with an effective content of 99%; the solid content of water glass is 30%, and the modulus is 2.7.

[0023] According to the mass ratio of materials: 75 parts of slag, 40 parts of fly ash, 7 parts of sodium hydroxide, 4 parts of water glass, water-solid ratio 0.28; according to the method of the present invention, the slurry is poured into shape, and the test block is at normal temperature. After curing for 28 days, dry, crush, and then grind to make gypsum retarder (its specific surface area is 371m 2 / kg).

Embodiment 3

[0025] The specific surface area of slag is 436m 2 / kg; the loss on ignition of fly ash is 9.6%, and its 0.08mm square hole sieve residue is 23%; sodium hydroxide is industrial grade, with an effective content of 99%; the solid content of water glass is 25%, and the modulus is 3.1.

[0026] According to the mass ratio of materials: 90 parts of slag, 50 parts of fly ash, 5 parts of sodium hydroxide, 5 parts of water glass, and water-solid ratio of 0.26; according to the method of the present invention, the slurry is poured into shape, and the test block is at normal temperature. After curing for 28 days, dry, crush, and then grind to make gypsum retarder (its specific surface area is 316m 2 / kg).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com