Heat-resisting waste asphalt regenerant and preparation method thereof

A technology of waste asphalt and regeneration agent, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems that the oil content cannot be stable for a long time in asphalt, the high temperature resistance of recycled asphalt is poor, and the difficulty of on-site regeneration is increased, and the wear resistance can be improved. Performance, improve aging resistance, improve the effect of low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

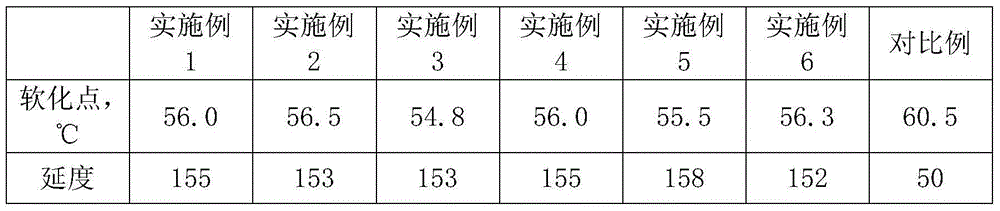

Examples

Embodiment 1

[0036] A heat-resistant waste asphalt regeneration agent, in parts by weight, comprises the following components:

[0037] 20 parts of rubber oil, 10 parts of waste styrene-butadiene rubber powder,

[0038] 20 parts of simethicone oil, 2 parts of nano-titanium oxide,

[0039] 1 part of plasticizer, 1 part of anti-aging agent.

[0040] Its preparation method comprises the following steps:

[0041] (1) Add 20 parts of rubber oil and 20 parts of simethicone oil into the stirring tank, heat to 170°C, stir and mix evenly, and set aside;

[0042] (2) Continue to add 10 parts of waste styrene-butadiene rubber powder and 2 parts of nano-titanium oxide to the stirring tank, stir for 25 minutes at 140 °C, and add 1 part of plasticizer and 1 part of anti-aging agent when it is naturally cooled to 60 °C , after continuing to stir for 25 minutes, cool to normal temperature to obtain a viscous liquid mixture, which is the heat-resistant waste asphalt regeneration agent of the present inv...

Embodiment 2

[0044] A heat-resistant waste asphalt regeneration agent, in parts by weight, comprises the following components:

[0045] 50 parts of rubber oil, 20 parts of waste styrene-butadiene rubber powder,

[0046] 30 parts of simethicone oil, 10 parts of nano-titanium oxide,

[0047] 4 parts of plasticizer, 5 parts of anti-aging agent.

[0048] Its preparation method comprises the following steps:

[0049] (1) Add 50 parts of rubber oil and 30 parts of simethicone oil into the stirring tank, heat to 200°C, stir and mix evenly, and set aside;

[0050] (2) Continue to add 20 parts of waste styrene-butadiene rubber powder and 10 parts of nano-titanium oxide into the stirring tank, stir for 60 minutes at 180 ° C, and add 4 parts of plasticizer and 5 parts of anti-aging agent when it is naturally cooled to 80 ° C , after continuing to stir for 60 minutes, cool to normal temperature to obtain a viscous liquid mixture, which is the heat-resistant waste asphalt regeneration agent of the p...

Embodiment 3

[0052] A heat-resistant waste asphalt regeneration agent, in parts by weight, comprises the following components:

[0053] 25 parts of rubber oil, 12 parts of waste styrene-butadiene rubber powder,

[0054] 22 parts of simethicone oil, 4 parts of nano-titanium oxide,

[0055] 1.5 parts of plasticizer, 2 parts of anti-aging agent.

[0056] Its preparation method comprises the following steps:

[0057] (1) Add 25 parts of rubber oil and 22 parts of simethicone oil into the stirring tank, heat to 175°C, stir and mix evenly, and set aside;

[0058] (2) Continue to add 12 parts of waste styrene-butadiene rubber powder and 4 parts of nano-titanium oxide into the stirring tank, stir for 30 minutes at 145°C, and add 1.5 parts of plasticizer and 2 parts of anti-aging agent when it is naturally cooled to 65°C , after continuing to stir for 30 minutes, cool to normal temperature to obtain a viscous liquid mixture which is the heat-resistant waste asphalt regenerant of the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com