Nanometer ceramic tile filler

A ceramic tile and pore agent technology, which is applied in the field of architectural decoration, can solve the problems of poor antifouling performance, high cost of polishing agent, and insufficient luminosity, and achieve the effects of improving antifouling ability, increasing gloss, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Get 100ml mass fraction of 30% silica sol, add 0.5ml10% sodium alkylbenzenesulfonate, 1.6ml neutral potassium methyl silicate and 0.2ml nonylphenol polyoxyethylene ether, 100ml water, Stir while adding to make each component fully mixed evenly, adjust the concentration of the polishing solution to 15% with water, at this time, measure the solution at 20-25°C with a density meter, and the density of the solution is 1.10g / cm 3 , use an atomizer to spray the polishing liquid on the micro powder brick, polish it 12 times, and use the photometer side to have a surface gloss of 93.

Embodiment 2

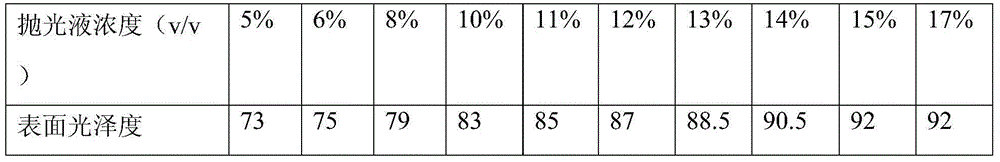

[0037] Purchase ten kinds of similar ceramic tiles circulating in the market, use a photometer to measure their surface gloss, and record them as shown in Table 3:

[0038] Table 3 The surface gloss of ten kinds of ceramic tiles circulating in the market

[0039] tile number

[0040] Compared with the surface gloss of the tiles sprayed with the polishing solution of the present invention and the tiles circulating on the market in Example 1, it is found that the surface gloss of the tiles using the polishing solution of the present invention is obviously better than the surface gloss of the tiles circulating on the market Spend.

Embodiment 3

[0042] The tiles sprayed with the polishing solution of the present invention in Example 1 and the tiles circulating on the market in Example 2 are respectively erected on the same plane, so that the tiles are upright at an angle of 90° to the horizontal plane. After 10 days, observe the amount of dust on the surface of the tiles , find that the ceramic tile surface that embodiment 1 makes is the smoothest.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com