Yilon staple fiber printed spun cotton

A technology of staple fiber and Yilun, which is applied in the treatment of dry-cleaning fiber products, textiles, papermaking, and textile materials. It can solve the problems of polyester and cotton with high static electricity, easy to absorb dust and pilling, and poor water absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

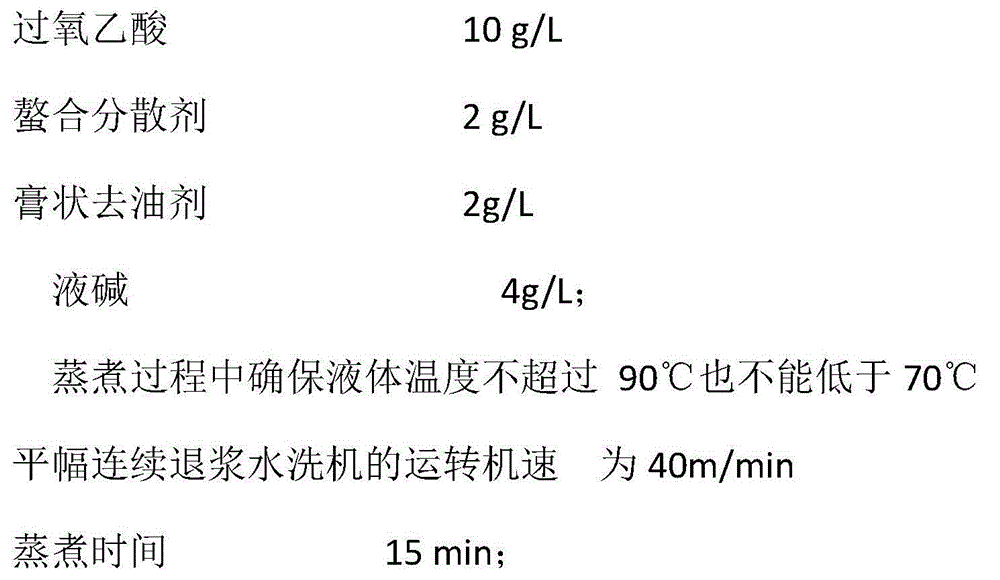

[0021] Yilun staple fiber printed spun cotton is woven from pure Yilun fiber raw materials, including the following steps: Step 1: Cooking treatment: Use an open-width continuous desizing washing machine to cook the gray cloth to make the size, weaving oil, Impurities and pigments are decomposed, shed, and removed from the cloth surface during the cooking process. During the cooking process, add:

[0022]

[0023] Step 2: Printing and steaming: Cool the gray cloth completed in step 1 at room temperature for more than 4 hours, then put it into the printing and dyeing scouring equipment, wherein:

[0024] The saturated steam pressure is greater than 0.4Mpa, the temperature is 185-190°C, and the continuous steaming time is 8-10min;

[0025] The proportioning that printing process adopts in described step 2 is: (g / L)

[0026]

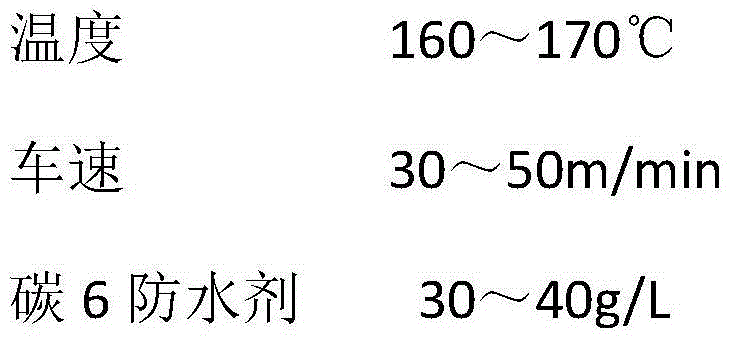

[0027] Step 3: Waterproof finishing and shaping: carried out in the raw material synthesis equipment, in which

[0028]

[0029] The ratio of pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com