Array photosensitive resistor laser collimation deformation measuring method and apparatus

A photoresistor and laser collimation technology, which is applied to measurement devices, uses optical devices, measures inclination, etc., can solve the problems of high supporting cost of atmospheric laser collimators, many restrictions on measuring point arrangement, and difficulty in automation. Achieve the effect of easy technology upgrade, low cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

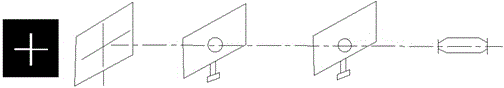

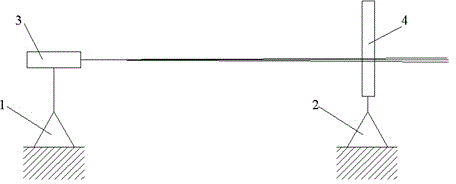

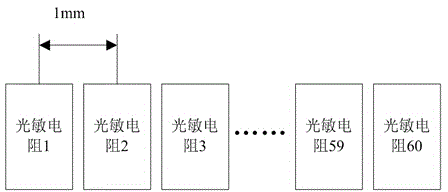

[0031] Such as figure 2 As shown, the present invention first forms a reference line by fixing the reference point 1 (one point) of the station and the laser direction (one line) emitted by the laser module 3 fixed on it, and the array photoresistor fixed on the measuring point 2 of the target object is displaced The array photoresistors with constant spacing in the sensor 4 are equivalent to setting up a standard scale, and jointly form an independent measurement system. Using the sensitivity of photoresistors to light, when the laser is irradiated on the photoresistor before and after, there is a significant difference in the resistance value of the photoresistor, and the voltage value distributed on all the photoresistors of the array is measured and read through the ADC scanning circuit, and then the resistance value is screened out throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com