Preparation for low-weightlessness rare earth-iron-boron magnetic body

A rare earth and magnet technology, used in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve problems such as poor corrosion resistance and limited application scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

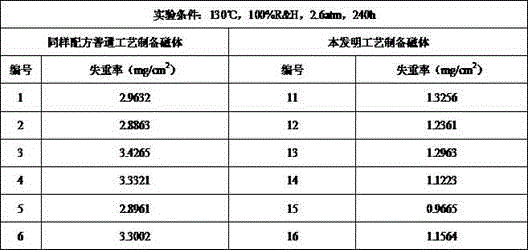

Embodiment 1

[0024] Rare earth-iron-boron magnets were prepared as follows, in the smelting step, the NdFeB alloy (RE, PrNd)-(Fe,M)-B composition is PrNd 31 Dy 0.6 Ho 0.6 Al 0.8 co 0.4 Cu 0.2 Ga 0.15 Zr 0.1 Fe 65.04 B 1.01 , the composition of the added nano-alloy RE-MM-N is PrNd35.2 Ti 35 V 29.65 N 0.15 ;

[0025] In the hydrogenation step, the RE-(Fe,M)-B cast sheet and the RE-MM-N steel ingot are hydrogenated separately. First, the pressure of the hydrogenation furnace is pumped down to below 1Pa, and then 0.06MPa is continuously charged into the hydrogenation furnace. Hydrogen, after the hydrogen absorption is complete, heat and dehydrogenate at 500°C to obtain a hydrogenated powder with a particle size within the range of 0.05mm to 2mm;

[0026] In the powder making step, (RE, PrNd)-(Fe, M)-B hydrogenated powder is added to the jet mill, 500ppm of antioxidant and 350ppm of lubricant are added respectively, and the magnetic powder is crushed by supersonic high-pressure nitr...

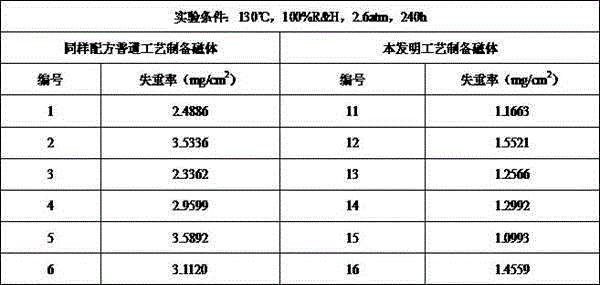

Embodiment 2

[0035] Rare earth-iron-boron magnets were prepared as follows, in the smelting step, the NdFeB alloy (RE, PrNd)-(Fe,M)-B composition is PrNd 31 Dy 0.6 Ho 0.6 Al 0.8 co 0.4 Cu 0.2 Ga 0.15 Zr 0.1 Fe 65.14 B 1.01 , the composition of the added nano-alloy RE-MM-N is PrNd 32.4 W 6.6 Ti 32.8 Cr 28 N 0.2 ;

[0036] In the hydrogenation step, the RE-(Fe,M)-B cast sheet and the RE-MM-N steel ingot are hydrogenated separately. First, the pressure of the hydrogenation furnace is pumped down to below 1Pa, and then 0.06Mpa is continuously charged into the hydrogenation furnace. Hydrogen, after the hydrogen absorption is complete, heat and dehydrogenate at 520°C to obtain hydrogenated powder with a particle size in the range of 0.05mm to 2mm;

[0037] In the powder making step, (RE, PrNd)-(Fe, M)-B hydrogenated powder is added to the jet mill, 800ppm of antioxidant and 200ppm of lubricant are added, and the magnetic powder is crushed by supersonic high-pressure nitrogen flow,...

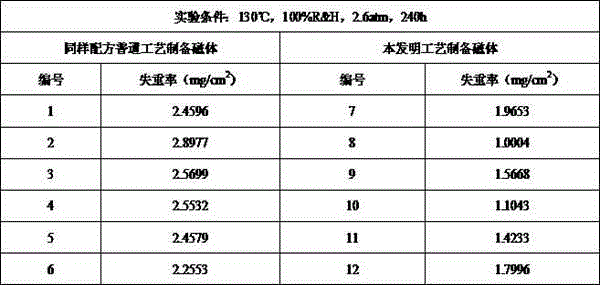

Embodiment 3

[0046] Rare earth-iron-boron magnets were prepared as follows, in the smelting step, NdFeB alloy (RE, PrNd)-(Fe,M)-B was PrNd 28.2 Tb 1.0 Dy 2.5 AL 0.3 Cu 0.18 co 0.8 Ga 0.12 Zn 0.1 Fe 65.8 B 1.0 , the composition of the added nano-alloy RE-MM-N is PrNd 32.5 W 4.4 Ti 48.6 Zr 14 N 0.25 ;

[0047] In the hydrogenation step, the RE-(Fe,M)-B cast sheet and the RE-MM-N steel ingot are hydrogenated separately. First, the pressure of the hydrogenation furnace is pumped down to below 1Pa, and then 0.065Mpa is continuously charged into the hydrogenation furnace. Hydrogen, after the hydrogen absorption is complete, heat and dehydrogenate at 530°C to obtain a hydrogenated powder with a particle size within the range of 0.05mm to 2mm;

[0048] In the powder making step, (RE, PrNd)-(Fe, M)-B hydrogenated powder is added to the jet mill, 400ppm of antioxidant and 400ppm of lubricant are added respectively, and the magnetic powder is crushed by supersonic high-pressure nitrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com