Sintered NdFeB permanent magnet based on particle combination adjustment and production method of sintered NdFeB permanent magnet

A manufacturing method and permanent magnet technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of easy oxidation of bottom materials, affecting product yield and particle size distribution, and affecting powder particle size, etc. Achieve the effect of improving corrosion resistance, reducing the amount of heavy rare earth, and improving the balance of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

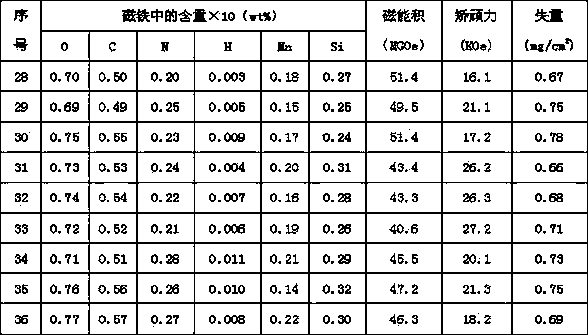

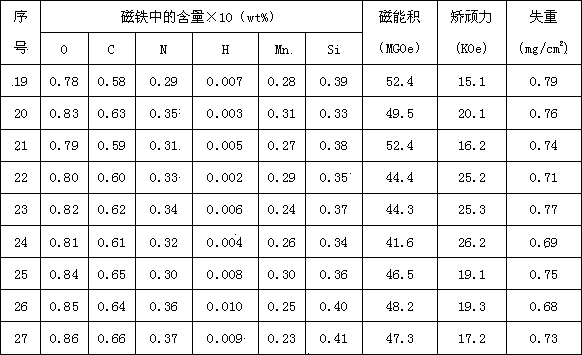

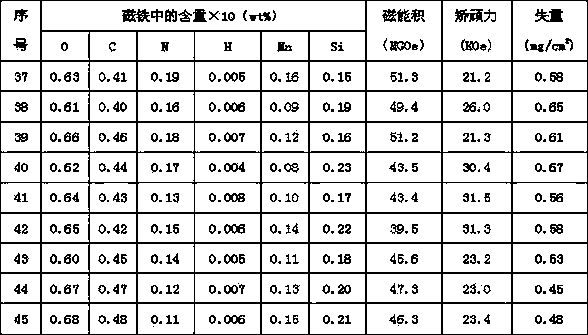

[0033] Raw materials containing Pr and Nd are batched according to serial numbers 1-9, and then the raw materials are loaded into vacuum melting and quick-setting equipment to prepare vacuum quick-setting alloy flakes as the first alloy; the average grain size of the alloy flakes of the first alloy is greater than 1.6 μm , less than 3.9 μm; then the raw materials containing Pr, Nd, and Dy components are batched according to the serial numbers 1-9, and then the raw materials are loaded into the vacuum quick-setting alloy sheet prepared by the vacuum melting quick-setting equipment as the second alloy; the second alloy The average grain size of the alloy sheet is greater than 1.1 μm and less than 2.9 μm; the first and second alloy smelting are both carried out in a vacuum Mn removal process, and the Mn removal process controls the heating temperature in the range of 400-1500 ° C and controls the vacuum degree to 5×10 3 Pa to 5×10 -2 Pa range, holding time 10-240 minutes; then c...

Embodiment 2

[0039] The raw materials containing Pr and Nd are batched according to the serial numbers 1-9, and then the raw materials are loaded into the double-roller cooled vacuum melting quick-setting equipment to prepare double-sided cooled quick-setting alloy flakes as the first alloy; the alloy flakes of the first alloy The average grain size is greater than 2.6 μm and less than 3.0 μm; then the raw materials containing Pr, Nd, and Dy are batched according to the serial numbers 1-9, and then the raw materials are loaded into the double-roller cooling vacuum melting and quick-setting equipment to prepare double-sided cooling Quick-setting alloy flakes are used as the second alloy; the average grain size of the alloy flakes of the second alloy is greater than 2.5 μm and less than 2.9 μm; the first and second alloy smelting are all carried out in a vacuum de-Mn process, and the de-Mn process controls the heating temperature 400-1450°C range, control vacuum 5×10 3 Pa to 5×10 -1 Pa ran...

Embodiment 3

[0043] The raw materials containing Pr and Nd are batched according to the serial numbers 1-9, and then the raw materials are loaded into the double-roller cooled vacuum melting quick-setting equipment to prepare double-sided cooled quick-setting alloy flakes as the first alloy; the alloy flakes of the first alloy The average grain size is greater than 2.6 μm and less than 3.0 μm; then the raw materials containing Pr, Nd, and Dy are batched according to the serial numbers 1-9, and then the raw materials are loaded into the double-roller cooling vacuum melting and quick-setting equipment to prepare double-sided cooling Quick-setting alloy flakes are used as the second alloy; the average grain size of the alloy flakes of the second alloy is greater than 1.1 μm and less than 1.5 μm; both the first and second alloy smelting are carried out in a vacuum de-Mn process, and the de-Mn process controls the heating temperature 500-1400℃ range, control vacuum degree 5×10 1 Pa to 5×10 -1P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com