Semiconductor laser multi-chip sintering clamp and sintering method

A technology of lasers and semiconductors, which is applied in semiconductor lasers, lasers, laser parts, etc., can solve the problems of high price of automation equipment, influence on the uniformity of applied force, and unsuitability for mass production, so as to reduce the probability of void generation, facilitate operation, The effect of high sintering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

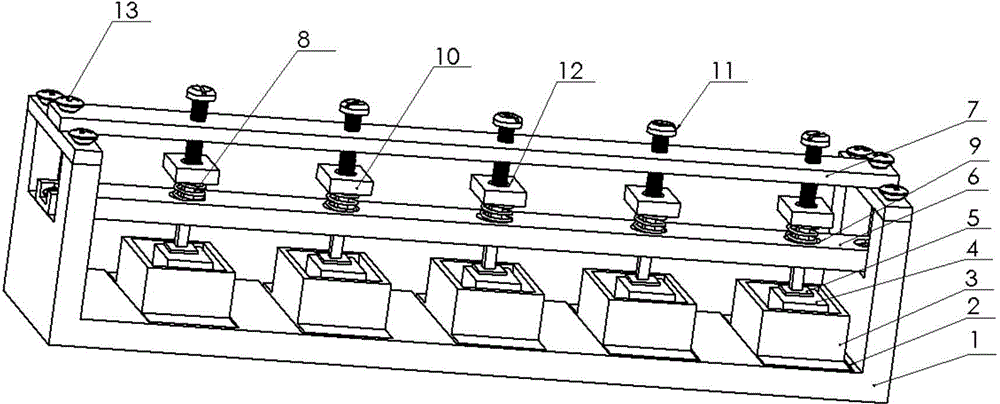

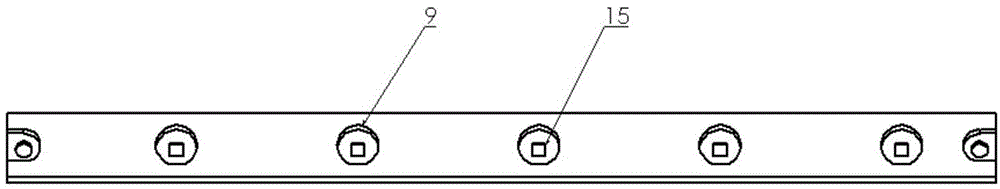

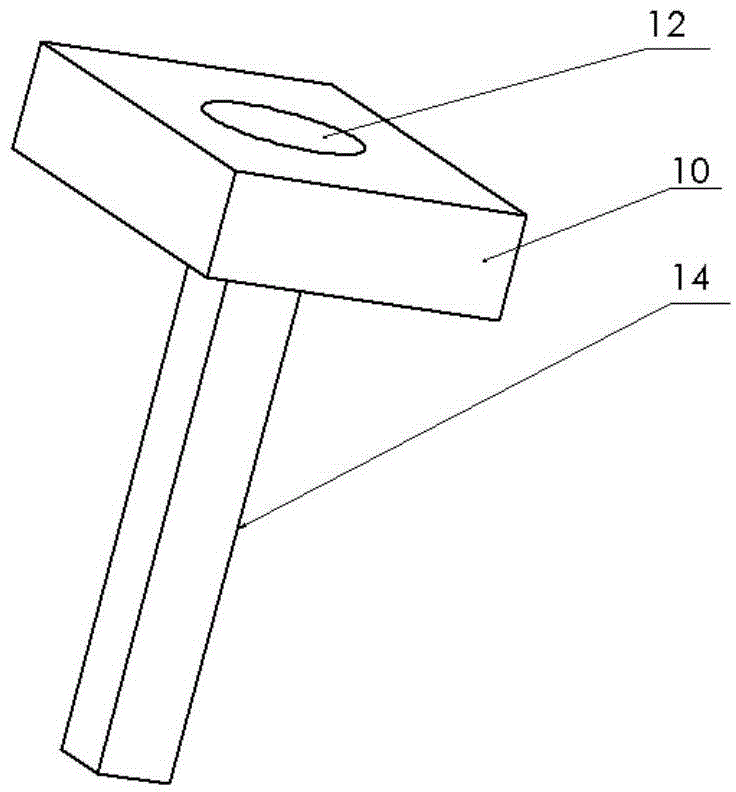

[0044] Semiconductor laser multi-chip sintering fixture, the structure is as follows figure 1As shown, it includes a main body 1, a lower pressing bar 6, an upper pressing bar 7, a top block 10 and a spring 8. The main body 1 is composed of a bottom plate and a side plate. The laser tube shell 3 is used to prevent the laser tube shell 3 from being displaced before and during sintering. The lower bead 6 and the upper bead 7 are rectangular strips, and a lower bead 6 and an upper bead 7 are fixed on the side plate of the main body 1 by fixing screws 13 at both ends, and are parallel to the surface of the main body bottom plate; the upper bead 7 There are 5 uniformly distributed thread holes on the top for screwing in the feed screw 11 and limiting the position; the lower pressure bar 6 is provided with 5 evenly distributed column holes 15, and the top block pressure column 14 passes through the column holes To extend to the bottom; the column holes of the lower bead and the thr...

Embodiment 2

[0048] A kind of method that semiconductor laser is carried out multi-chip sintering, utilizes the sintering jig described in embodiment 1, and the steps are as follows:

[0049] (1) Place the heat sink 4 whose upper surface has been prefabricated with solder into the laser tube shell 3 with solder;

[0050] (2) Place the COS 5 at the designated position of the above-mentioned heat sink 4 to ensure that the light output position meets the requirements;

[0051] (3) Place the laser tube shells with the heat sink and COS placed in the laser limiting groove 2 of the main body one by one, ensuring that the upper force point of the COS is directly below the top block pressure column 14;

[0052] (4) Rotate the feed screws 11 one by one, move the top block pressure column 14 down through spring compression, and press the bottom of the top block pressure column 14 to the point of force on the COS. When the screw is fed, ensure that its top is located at the feed screw In the limit g...

Embodiment 3

[0057] A semiconductor laser multi-chip sintering fixture, as described in Embodiment 1, the difference is that the surface of the main body 1 bottom plate is provided with two rows of laser limiting grooves 2, each row of 5 laser limiting grooves, the structure is as follows Figure 4 shown. Correspondingly, the lower pressing bar is two rectangular strips side by side, and the upper pressing bar is also two side-by-side rectangular strips. Align top and bottom. The number of chips that can be simultaneously sintered by this jig is twice that of the jig in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com