Acid gas vertical reactor and processing method

A vertical reactor, acid gas technology, applied in chemical instruments and methods, separation methods, dispersed particle separation and other directions, can solve the problems of inability to produce valuable oleum, easy deterioration of sodium sulfide, difficult operation of the device, etc., to avoid The effect of blocking pipelines and pumps, omitting liquid phase transfer pipelines and pumps, and preventing crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

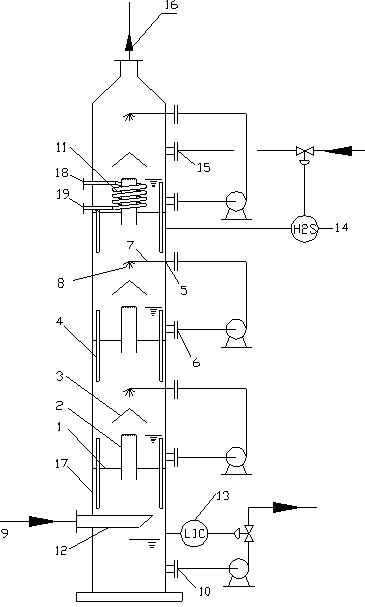

[0041] In this embodiment, the acid gas vertical reactor is provided with 3-stage reaction zones.

[0042] Such as figure 1 As shown, the present invention is a schematic diagram of an acid gas treatment process, using acid gas and NaOH solution as raw materials to react and generate the acid gas treatment process of product NaHS.

[0043] The reaction process of the acid gas treatment method of the present invention is specifically illustrated by taking the reactor as an example of a total of three-stage reaction zones, one-stage reaction zone, two-stage reaction zone, and three-stage reaction zone: when using the sour gas vertical reactor of the present invention to process acid gas, The acid gas enters the buffer zone through the acid gas inlet, and then enters the first-stage reaction zone. The absorption liquid is the reaction product liquid (including Na 2 S and NaHS), the absorption liquid forms a liquid film in the primary reaction zone through the nozzle, and when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com