Diatomite/nylon-6 composite material and preparation method thereof

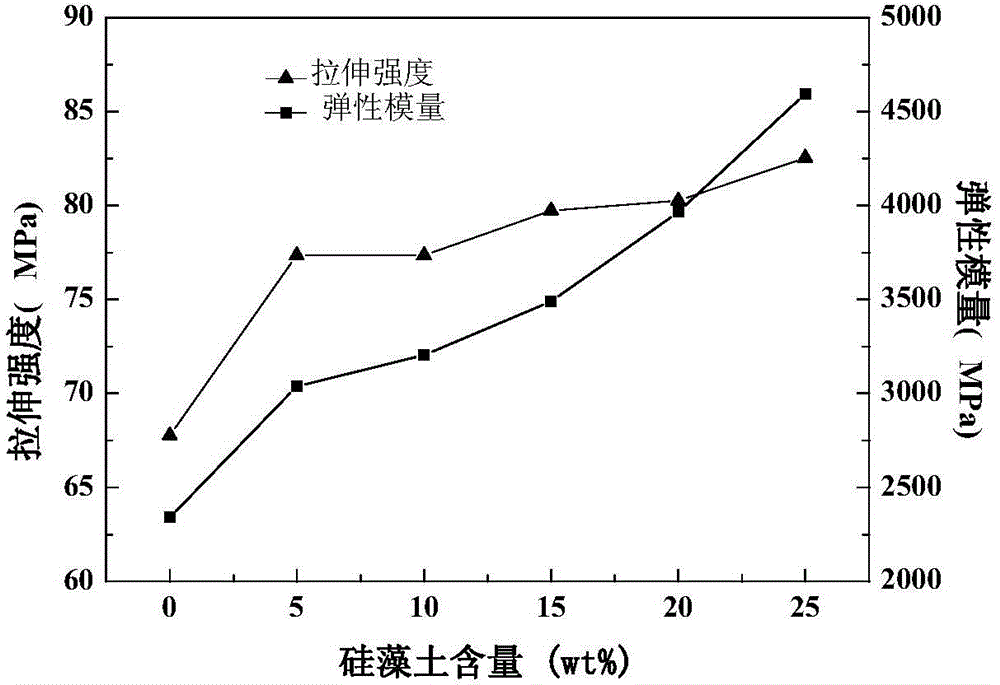

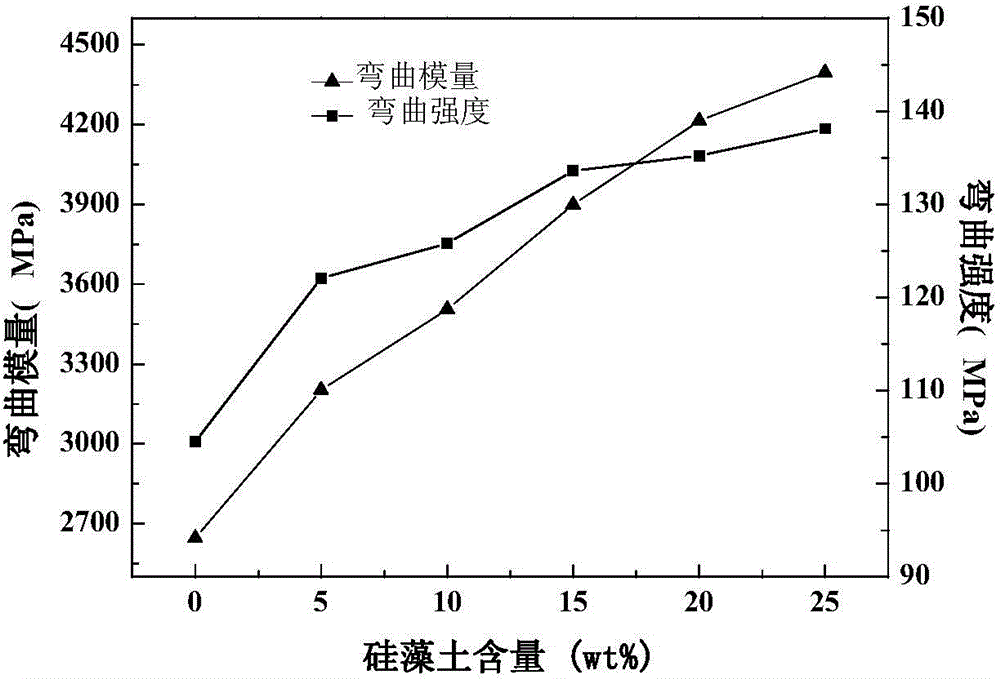

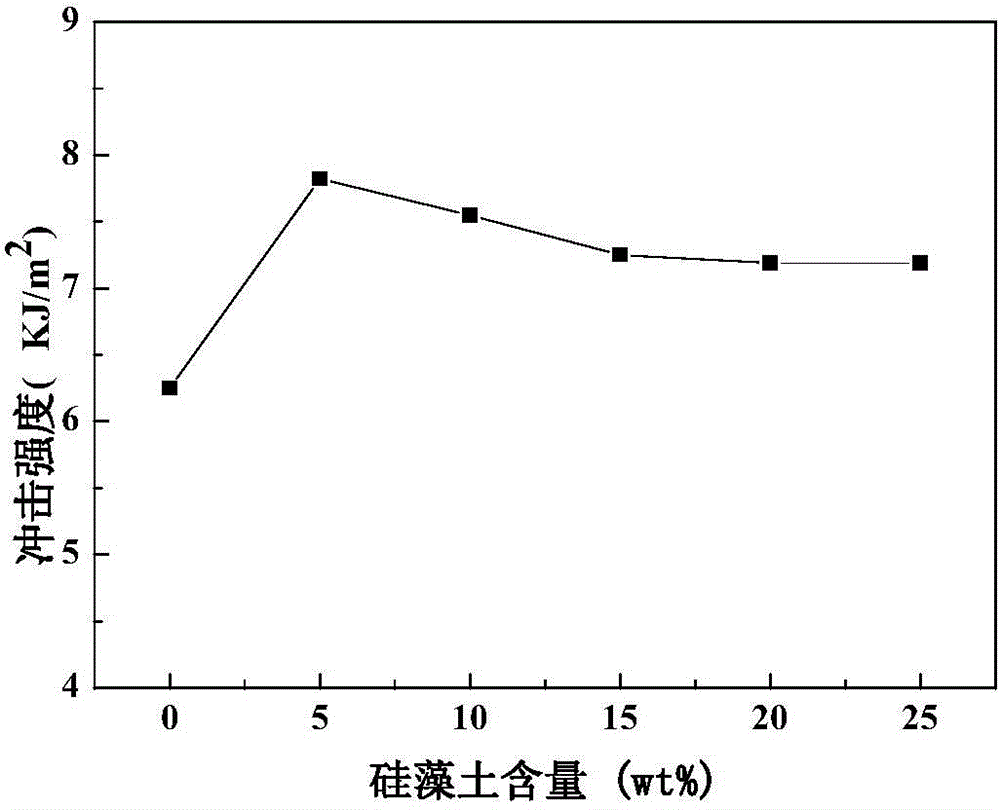

A composite material and diatomite technology, which is applied in the field of plastic filling and modification, can solve the problems of low impact strength and poor dimensional stability, and achieve the effects of improving strength, high surface free energy and high adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This comparative example is composed of the following raw materials in terms of weight percentage: 95% of nylon-6, 5% of surface-treated diatomite, and the total amount of raw materials is 100%. The twin-screw extruder used has a diameter of 25cm, an aspect ratio of 32:1, a rotational speed of 210r / min, and a processing temperature of 230°C in the first zone, 235°C in the second zone, 240°C in the third zone, 245°C in the fourth zone, and 240 °C in the head. ℃.

[0056] The diatomite / nylon-6 composite material of this example was prepared according to the above preparation method.

Embodiment 2

[0058] This comparative example is composed of the following raw materials in terms of weight percentage: nylon-6 is 90%, surface-treated diatomite is 10%, and the total amount of raw materials is 100%. The twin-screw extruder used has a diameter of 25cm, an aspect ratio of 32:1, a rotational speed of 210r / min, and a processing temperature of 230°C in the first zone, 235°C in the second zone, 240°C in the third zone, 245°C in the fourth zone, and 240 °C in the head. ℃.

[0059] The diatomite / nylon-6 composite material of this example was prepared according to the above preparation method.

Embodiment 3

[0061] This comparative example is composed of the following raw materials in terms of weight percentage: nylon-6 is 85%, surface-treated diatomite is 15%, and the total amount of raw materials is 100%. The twin-screw extruder used has a diameter of 25cm, an aspect ratio of 32:1, a rotational speed of 210r / min, and a processing temperature of 230°C in the first zone, 235°C in the second zone, 240°C in the third zone, 245°C in the fourth zone, and 240 °C in the head. ℃.

[0062] The diatomite / nylon-6 composite material of this example was prepared according to the above preparation method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com