Fuzzy forecasting model based method for detecting pulp concentration in ore grinding process of dressing plant

A technology of fuzzy prediction and pulp concentration, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems affecting the accuracy and generalization ability of fuzzy prediction models, rule explosion, fuzzy model design and application difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

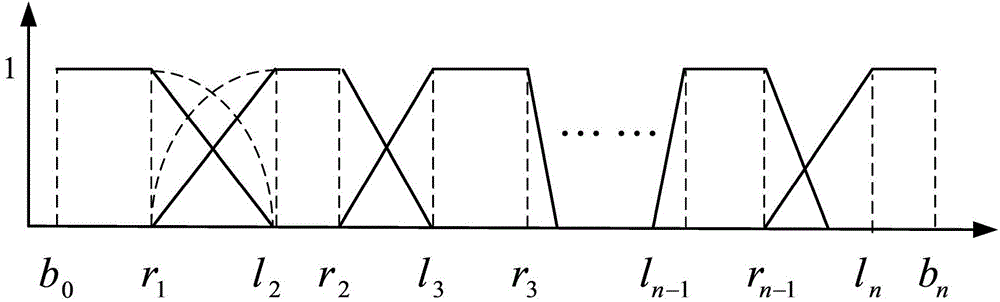

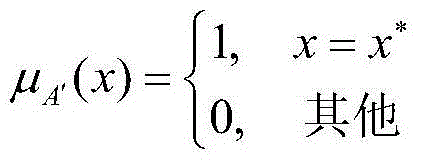

Method used

Image

Examples

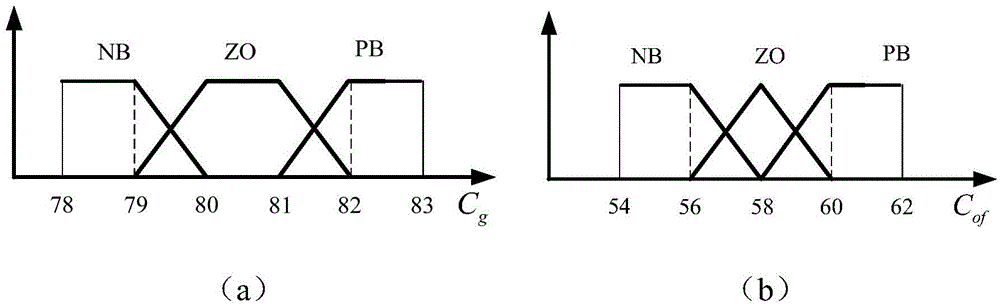

Embodiment

[0112] Taking the grinding process of a #4 mill in a concentrator as an example, a specific application of the present invention is given. The model of the steel ball mill equipped in the grinding process is QM44Φ3.6×4.5, and it forms a closed-circuit grinding system with the spiral classifier of the model 2FLCΦ2400×14050. The working process is as follows: the crushed raw ore is controlled by the vibrating feeder and conveyed to the ball mill for grinding through the belt; at the entrance of the mill, the return sand water will send the over-coarse material returned by the classifier into the mill for re-grinding, and adjust The pulp concentration in the mill; the pulp at the outlet of the mill flows into the spiral classifier, and the discharge water is used to wash the material and mainly control the particle size of the overflow material entering the next process; the spiral classifier separates the material according to the particle size, fine The grain grade product is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com