Synthesis method of lithium ion battery cathode nano-powder by strengthening solid-phase reaction

A lithium-ion battery and nano-powder technology, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficult to realize industrialized production, long nano-powder process cycle, low yield and production efficiency, etc. And the effect of uniform particle size, good electrochemical performance, and complete lattice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

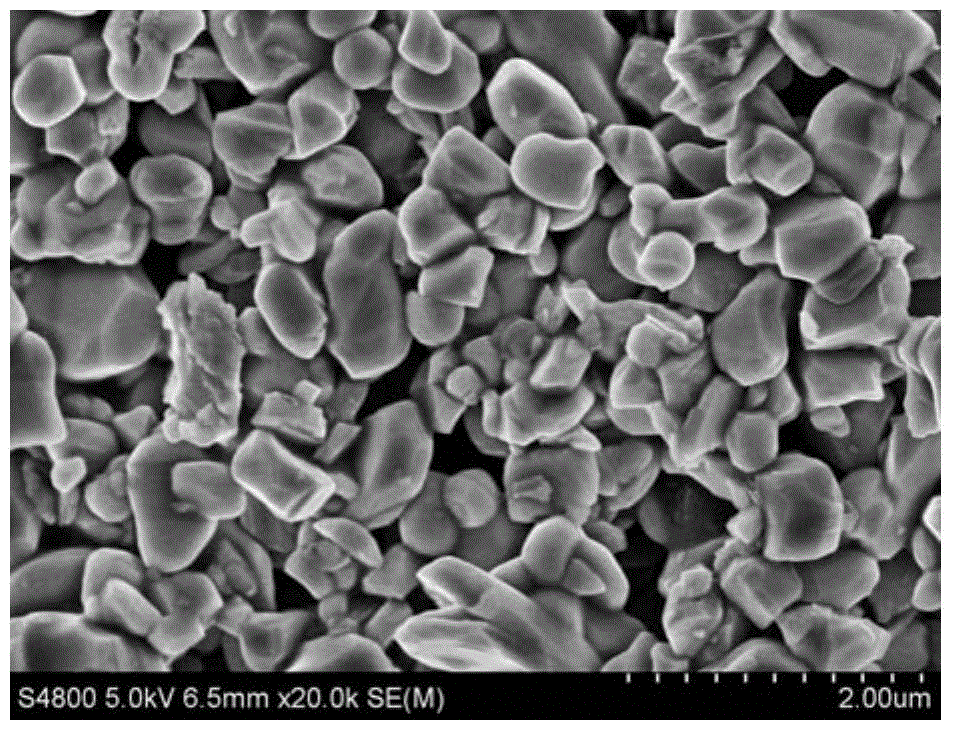

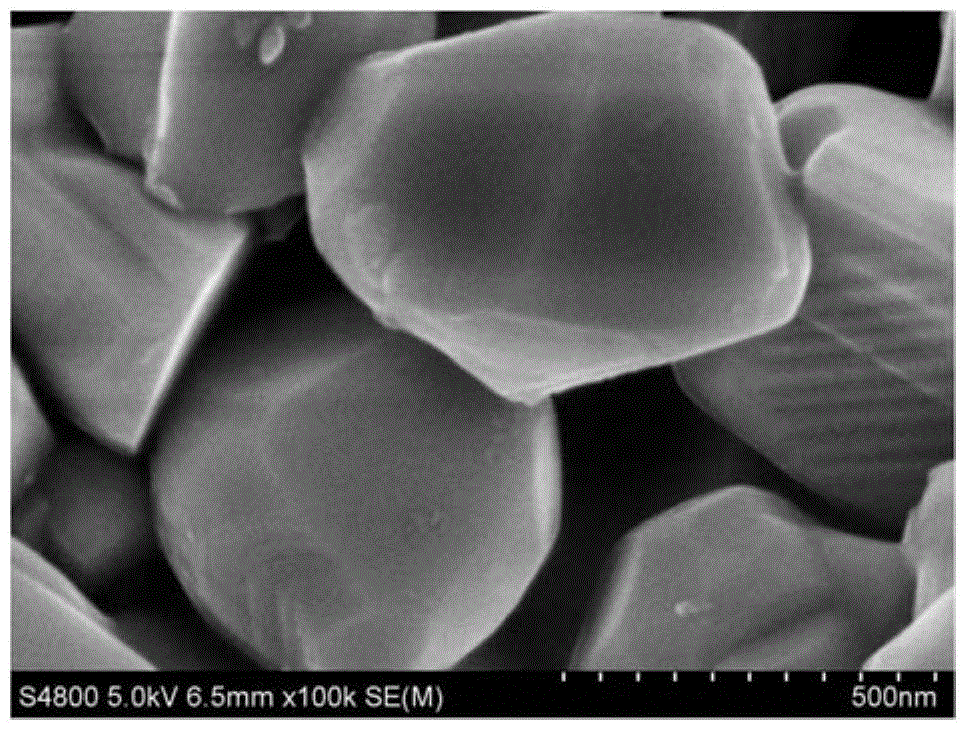

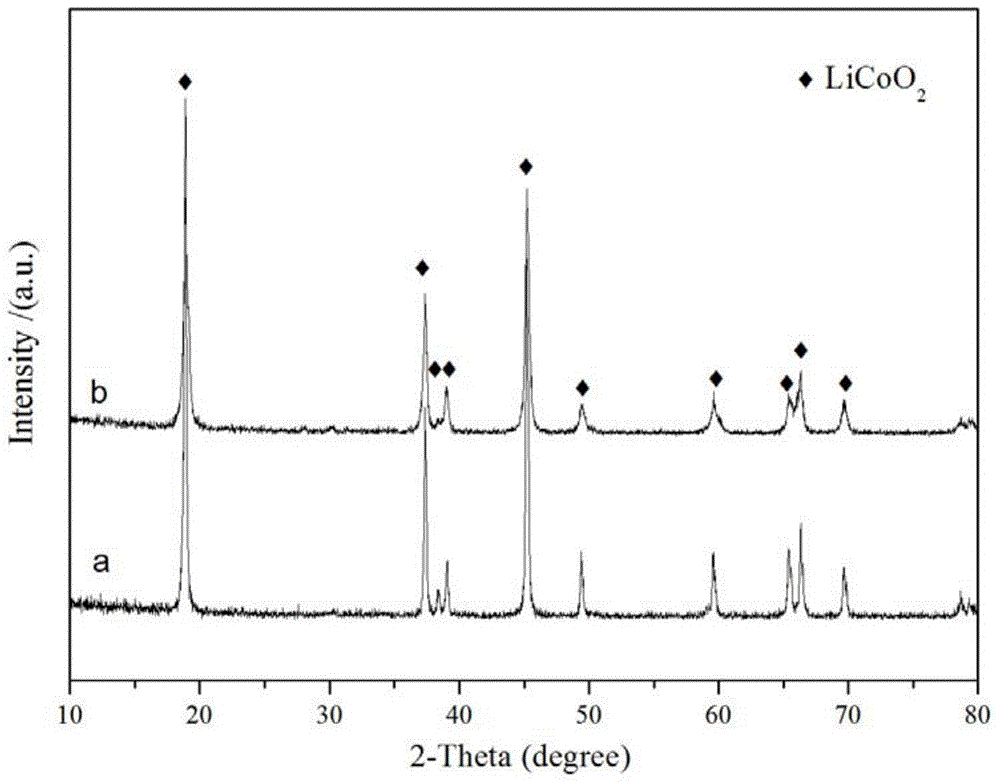

[0031] Refer to attached picture 1. Preparation of LiCoO 2 Nanopowders, first commercially available (average particle size > 5 μm) CoCO 3 Powder and Li 2 CO 3The powders are measured separately according to the molar ratio of Li:Co ratio of 1:1, and the ingredients are mixed according to the ball-to-material ratio of 15:1, and put into the ball mill jar. After the powder mass percentage is 0.5% ball milling aid (the mixture of alcohol and low molecular weight polymer), the mixture is carried out high-energy ball milling treatment 10h in the planetary ball mill, and the rotating speed of ball mill is 300~400r / min, and the particle size is in the nanoscale After the ball milling product is dried in a drying oven, it is placed in a calciner for solid-phase thermal decomposition-diffusion reaction to obtain LiCoO 2 For nano powder, the reaction temperature is 600°C, and the reaction time is 3h; the low-temperature treated powder is calcined at 900°C for 1h, cooled with the fu...

Embodiment 2

[0034] Refer to attached picture 6. Preparation of LiNi 0.5 mn 1.5 o 4 Nano-powder, first commercially available (average particle size > 5μm) MnCO 3 、NiCO 3 Powder and Li 2 CO 3 The powders are respectively measured according to the molar ratio of Li:Ni:Mn ratio of 2:1:3, and the proportioning is carried out according to the ball-to-material ratio of 15:1, put into a ball mill jar, and the mixture is subjected to high-energy ball milling for 10 hours. The ball mill jar is agate. The ball is made of zirconia, and a ball milling aid with a powder mass percentage of 1% is added to the ball mill tank; after the ball mill product is dried in a drying oven, it is put into a calciner for solid-phase thermal decomposition-diffusion reaction synthesis, and the reaction The temperature is 700°C and the reaction time is 5h. The low-temperature treated powder was calcined at 900°C for 1 hour, cooled with the furnace, and pulverized to obtain the desired product.

Embodiment 3

[0036] Refer to attached picture 7a and 7b, Preparation of LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 Nano-powder, first commercially available (average particle size > 5μm) MnCO 3 、NiCO 3 、CoCO 3 Powder and Li 2 CO 3 The powders are respectively measured according to the molar ratio of Li:Ni:Mn ratio of 3.1:1:1, and the ingredients are prepared according to the ball-to-material ratio of 15:1. Add a ball milling aid with a powder mass percentage of 1% in the ball milling tank, and perform high-energy ball milling on the mixture for 10 hours. After the ball milling product is dried in a drying oven, it is put into a calciner for solid-phase thermal decomposition-diffusion reaction synthesis, and the reaction The temperature is 700°C, and the reaction time is 7 hours. The low-temperature-treated powder is calcined at 950°C for 3 hours, cooled with the furnace, and pulverized to obtain the desired product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com