Dispersion type wet toilet paper and manufacturing method thereof

A manufacturing method and technology of wet toilet paper, which is applied in the field of nonwoven materials, can solve the problems that ordinary toilet paper does not have disease prevention, detoxification, antivirus, feces or secretions cannot be removed, and can not relieve physical and mental pain, so as to improve sterilization and disinfection Effect, excellent bactericidal effect, strong adsorption and anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

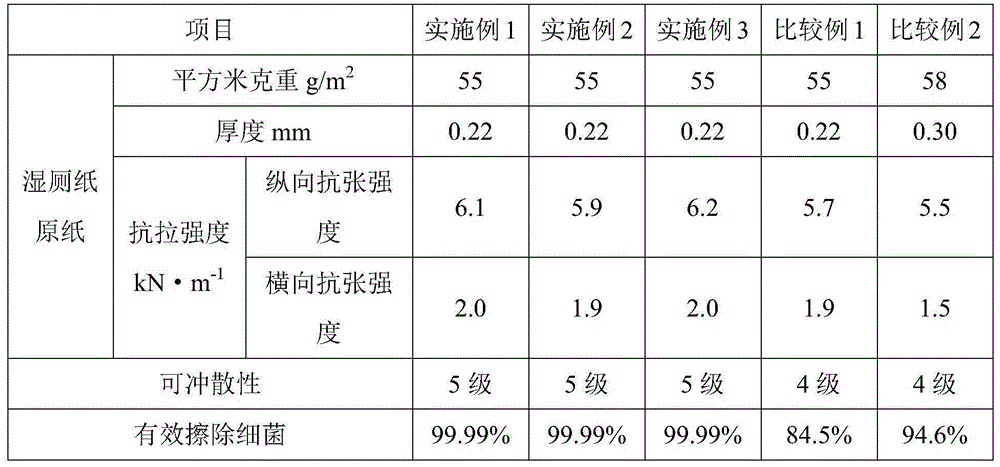

Examples

Embodiment 1

[0031] Raw material: 25% polylactic acid fiber, 5% flax fiber, 70% wood pulp fiber;

[0032] Non-woven production: polylactic acid fiber, flax fiber and wood pulp fiber are mixed and formed into a web by air-flow drying method, then dried and rolled to form a non-woven fabric, that is, flushable wet toilet paper base paper; liquid, cut the non-woven fabric, fold it, put it into a plastic bag and seal it after completely soaking in the wetting liquid.

[0033] Moisturizing solution formula: 10g corn silk, 20g cnidium, 10g angelica, 15g angelica, 12g Baibu, 30g mugwort leaves, 10g pepper leaves, 10g kaempferia, 30g iron horsewhip, 20g Daqingye, 5g citric acid, 15g coconut oil, 20g orange peel, 500g water.

[0034]The preparation method of the wetting liquid is as follows: after weighing each component according to the above weight ratio, the corn silk, cnidium, angelica, angelica, hundred leaves, mugwort leaves, pepper leaves, kaempferia, iron horsewhip, big green leaves 1. Ad...

Embodiment 2

[0036] Raw materials: 28% polylactic acid fiber, 6% flax fiber, 66% wood pulp fiber;

[0037] Non-woven production: polylactic acid fiber, flax fiber and wood pulp fiber are mixed and formed into a web by air-drying method, then dried and rolled to form a non-woven fabric; the wetting liquid is prepared according to the weight ratio, and the non-woven fabric is cut, Fold it, put it in a plastic bag and seal it after fully soaking in the wetting solution.

[0038] Moisturizing solution formula: 8g corn silk, 18g cnidium, 8g angelica, 10g angelica, 12g Baibu, 28g mugwort leaves, 8g pepper leaves, 6g kaempferia, 25g iron horsewhip, 16g Daqingye, 3g citric acid, 10g coconut oil, 15g orange peel, 500g water.

[0039] The preparation method of the wetting liquid is as follows: after weighing each component according to the above weight ratio, the corn silk, cnidium, angelica, angelica, hundred leaves, mugwort leaves, pepper leaves, kaempferia, iron horsewhip, big green leaves 1. A...

Embodiment 3

[0041] Raw materials: 26% polylactic acid fiber, 4% flax fiber, 70% wood pulp fiber;

[0042] Non-woven production: polylactic acid fiber, flax fiber and wood pulp fiber are mixed and formed into a web by air-drying method, then dried and rolled to form a non-woven fabric; the wetting liquid is prepared according to the weight ratio, and the non-woven fabric is cut, Fold it, put it in a plastic bag and seal it after fully soaking in the wetting solution.

[0043] Moisturizing solution formula: 5g corn silk, 15g cnidium, 8g angelica, 10g angelica, 10g Baibu, 20g mugwort leaves, 5g pepper leaves, 5g kaempferia, 20g iron horsewhip, 15g Daqingye, 3g citric acid, 10g coconut oil, 15g orange peel, 500g water. After weighing each component according to the above weight ratio, add corn silk, cnidium fruit, angelica, angelica, hundred leaves, mugwort leaves, pepper leaves, kaempferia, iron horsewhip, big green leaves, orange peel into water and soak for 2 hours, and decoct for 15 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com