Method for predicting small-angle welding temperature field of rotating arc low-alloy structural steel

A technology of rotating arc and welding temperature, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve problems such as welding defects and losses, and achieve the effect of reducing experimental costs and workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

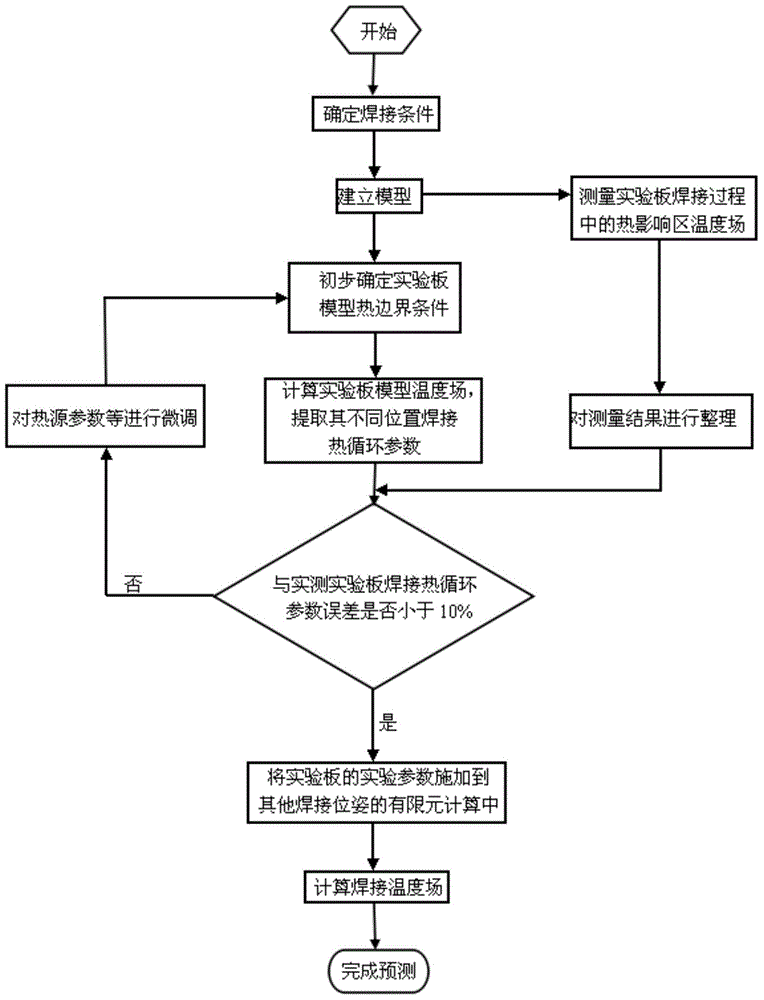

Method used

Image

Examples

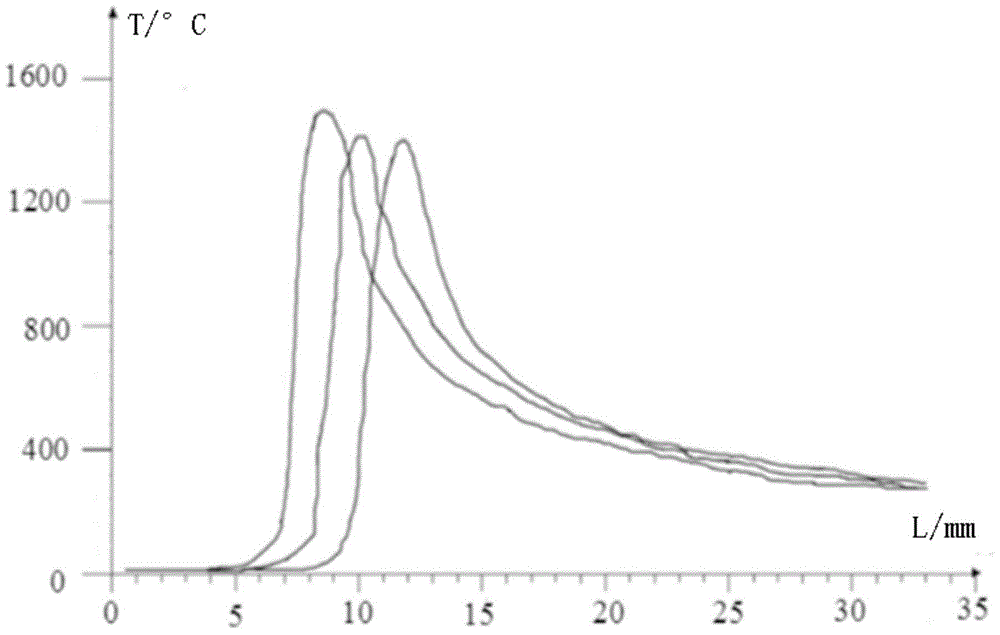

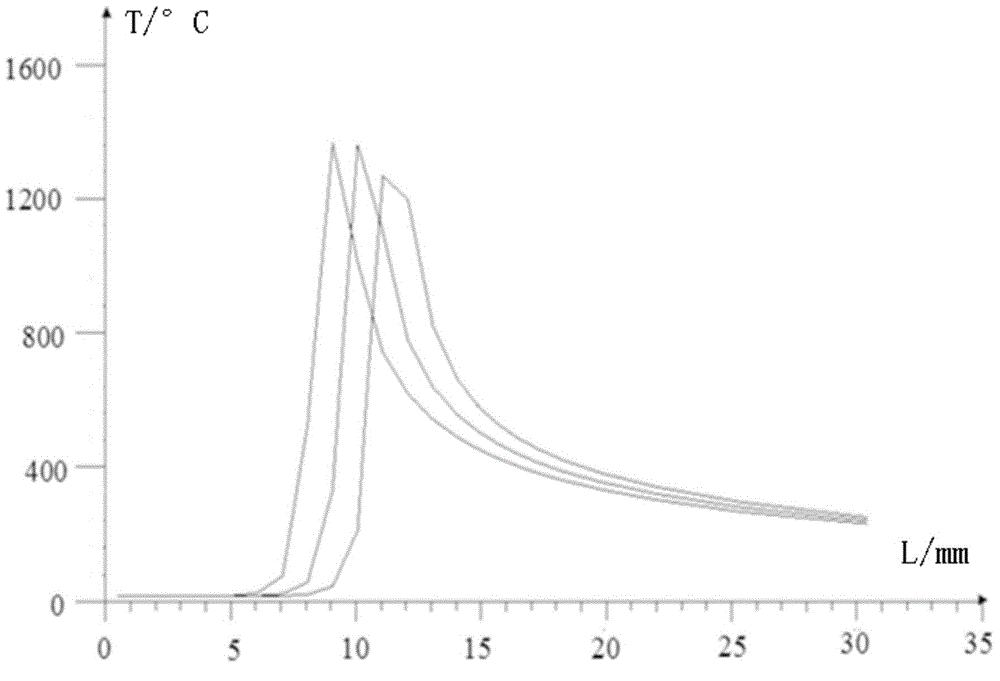

Embodiment 1

[0033] Embodiments of the present invention are described in detail below: the welding method that the present invention adopts is rotating arc CO. 2 Welding, the temperature measurement method is to measure the temperature by punching holes on the back of the thermocouple. S355J2G3 low-alloy structural steel was selected as the experimental material. The solidus temperature of the material is 1440°C, the liquidus temperature is 1505°C, and the latent heat of phase change is 270000J / kg. The size of the weldment is 100mm×100mm×5mm. Use the PHOENIX300 welding machine made in Germany to carry out rotary arc CO on the base metal 2 Gas-shielded welding plate surfacing experiment, the thermal efficiency is 0.75, the welding slope is 5°, and the welding process parameters are shown in Table 1. The thermal cycle curve was measured by a platinum-rhodium 30-platinum-rhodium 6 thermocouple, and transmitted to a computer equipped with SYSYWELD software of the French ESI company through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com