Manufacturing method capable of improving mechanical performance of thick 7050-T7451 aluminum alloy plate

A technology of mechanical properties and processing methods, which is applied in the processing field of improving the mechanical properties of 7050-T7451 aluminum alloy thick plates, can solve the problems of uniformity affecting mechanical properties, weak superplastic forming process, and increase in the number of precipitated phases. The effect of eliminating the microstructure, eliminating the heat-engine affected zone and the heat-affected zone, and eliminating the heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Heat the heat treatment furnace to 450°C, put the 7050-T7451 aluminum alloy original thick plate into the heat treatment furnace and heat it for 6 hours to obtain the heat-treated 7050 aluminum alloy plate;

[0029] (2) Quench and straighten the heat-treated 7050 aluminum alloy plate;

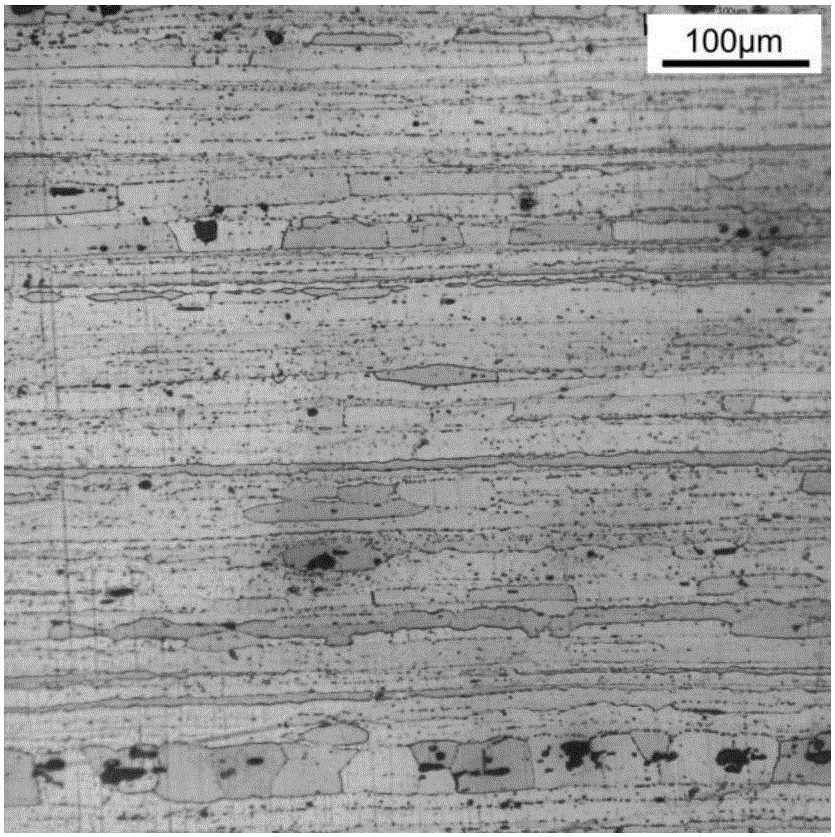

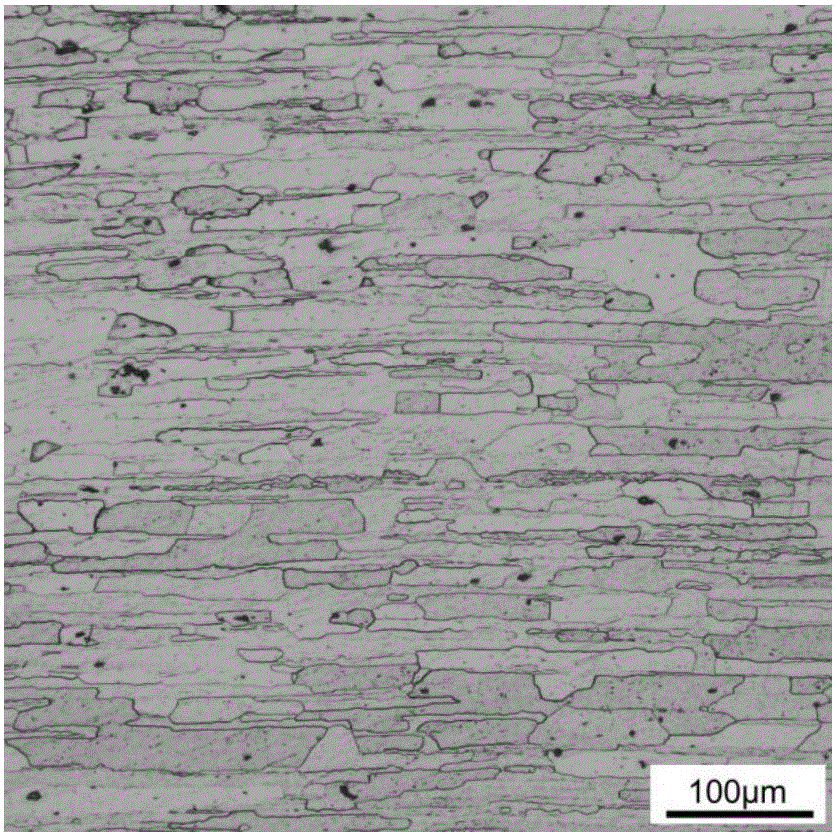

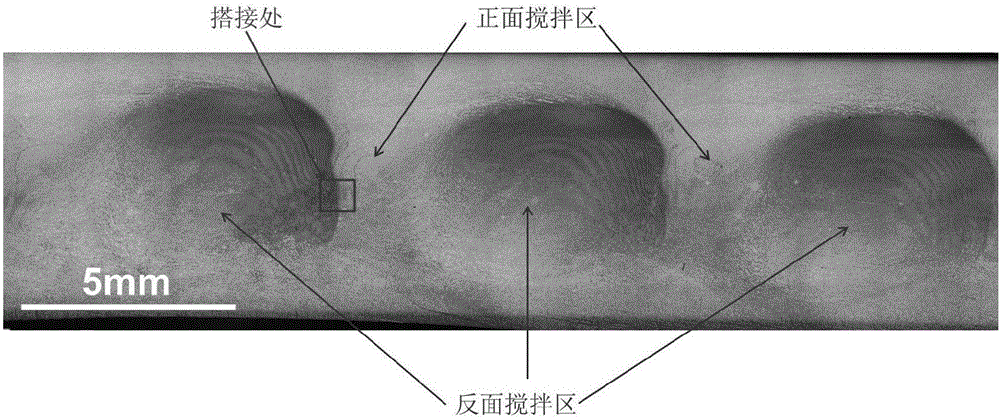

[0030] (3) For frontal friction stir processing, the inclination angle of the central axis of the stirring head is 2.5°, the speed of the stirring head is 500~700rpm, the processing speed is 80~120mm / min, and the shoulder overlap between each pass is 35~65% , Processing 5 passes;

[0031] (4) Perform friction stir processing on the reverse side, in which the center insertion point of the processing stirring needle is offset from the center insertion point of the first pass of the front stirring needle by 30~55%, the inclination angle of the central axis of the stirring head is 2.5°, and the stirring head speed is 500~700rpm , The processing speed is 80~120mm / min, the shoulder overlap betwe...

Embodiment 2

[0034] (1) Heat the heat treatment furnace to 500°C, put the 7050-T7451 aluminum alloy original thick plate into the heat treatment furnace and heat it for 2.5 hours to obtain the heat-treated 7050 aluminum alloy plate;

[0035] (2) Quench and straighten the heat-treated 7050 aluminum alloy plate;

[0036] (3) For frontal friction stir processing, the inclination angle of the central axis of the stirring head is 2.5°, the speed of the stirring head is 500~700rpm, the processing speed is 80~120mm / min, and the shoulder overlap between each pass is 35~65% , Processing 5 passes;

[0037] (4) Perform friction stir processing on the reverse side, in which the center insertion point of the processing stirring needle is offset from the center insertion point of the first pass of the front stirring needle by 30~55%, the inclination angle of the central axis of the stirring head is 2.5°, and the stirring head speed is 500~700rpm , The processing speed is 80~120mm / min, the shoulder overlap bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com