Road anti-dazzle board

An anti-glare board and highway technology, applied in the field of highway transportation facilities, can solve the problems of heavy weight, inconvenient transportation, long construction time, etc., and achieve the effects of convenient transportation and on-site construction, increased diffuse reflection effect, and reduced bulk density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

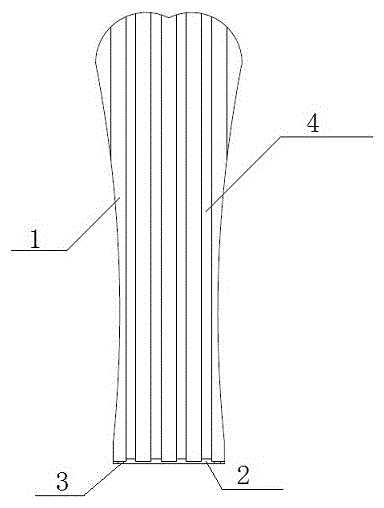

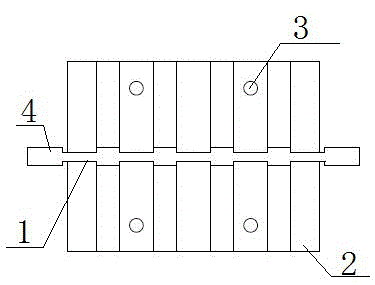

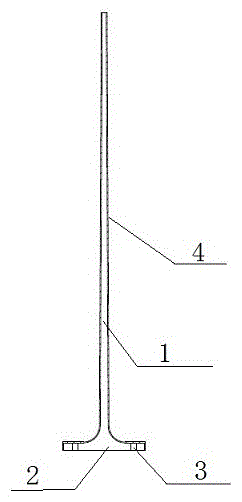

Image

Examples

Embodiment 1

[0066] A road anti-glare board, made of ultra-high performance powder concrete, the ultra-high performance powder concrete includes the following raw materials in parts by weight:

[0067] 400 parts of 52.5 grade Portland cement with an average particle size of 30-60 μm;

[0068] 100 parts of micro-silicon powder with an average particle size of 5-20 μm and a SiO2 content of ≥85%;

[0069] 100 parts of quartz stone powder with an average particle size of 50-100 μm;

[0070] 150 parts of limestone powder with an average particle size of 10-30 μm;

[0071] 450 parts of glass microbead powder with a particle size of 0.63 mm or less;

[0072] 500 parts of river sand with particle size below 1.63mm;

[0073] 16 parts of high-efficiency water reducing agent with water reducing rate greater than 30%;

[0074] 30 parts of inorganic pigment powder;

[0075] 180 parts of water;

[0076] 80 copper-plated fibers with an average diameter of 0.15 mm and a length of 8 to 12 mm;

[007...

Embodiment 2

[0087] Except that each mass portion proportioning of raw materials is different, other is the same as embodiment 1;

[0088] The self-compacting powder concrete is made of the following raw materials in proportion by mass:

[0089] 450 parts of 52.5 grade Portland cement with an average particle size of 30-60 μm;

[0090] 115 parts of micro-silica fume with an average particle size of 5-20 μm and a SiO2 content of ≥85%;

[0091] 115 parts of quartz stone powder with an average particle size of 50-100 μm;

[0092] 175 parts of limestone powder with an average particle size of 10-30 μm;

[0093] 500 parts of glass microbead powder with a particle size below 0.63mm;

[0094] 525 parts of river sand with particle size below 1.63mm;

[0095] 18 parts of high-efficiency water reducing agent with water reducing rate greater than 30%;

[0096] 32 parts of inorganic pigment powder;

[0097] 190 parts of water;

[0098] 85 copper-plated fibers with an average diameter of 0.15 mm...

Embodiment 3

[0101] Except that each mass portion proportioning of raw materials is different, other is the same as embodiment 1;

[0102] The self-compacting powder concrete is made of the following raw materials in proportion by mass:

[0103] 500 parts of 52.5 grade Portland cement with an average particle size of 30-60 μm;

[0104] 125 parts of micro-silicon powder with an average particle size of 5-20 μm and a SiO2 content of ≥85%;

[0105] 125 parts of quartz stone powder with an average particle size of 50-100 μm;

[0106] 200 parts of limestone powder with an average particle size of 10-30 μm;

[0107] 525 parts of glass microbead powder with a particle size of 0.63 mm or less;

[0108] 550 parts of river sand with particle size below 1.63mm;

[0109] 19 parts of high-efficiency water reducing agent with water reducing rate greater than 30%;

[0110] 35 parts of inorganic pigment powder;

[0111] 200 parts of water;

[0112] 90 copies of copper-plated fibers with an average ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com