Device for converting microalgae adherent culture and liquid submerged culture

A liquid immersion, microalgae technology, applied in enzymology/microbiology devices, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problem of inability to achieve multiple repeated conversions of liquid immersion culture and adherent culture, etc. problem, to achieve the effect of rapid high-density culture, reduced culture cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

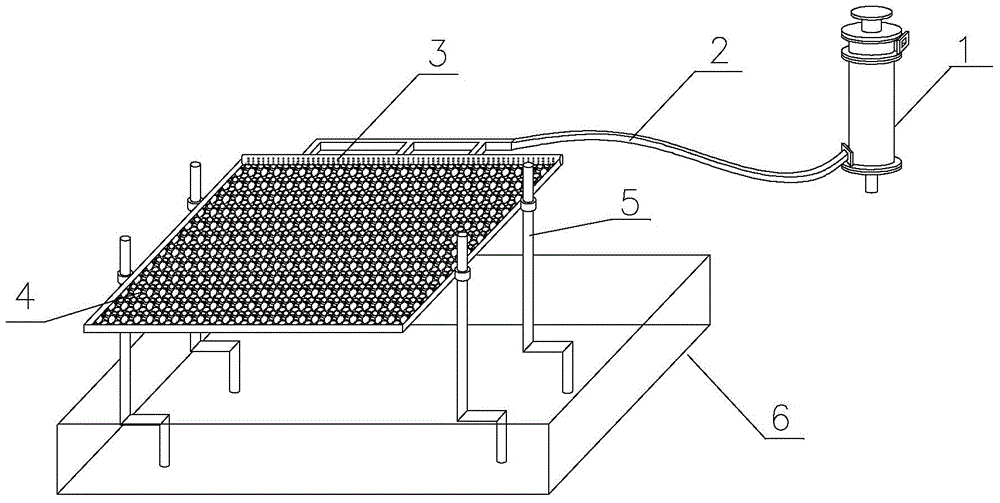

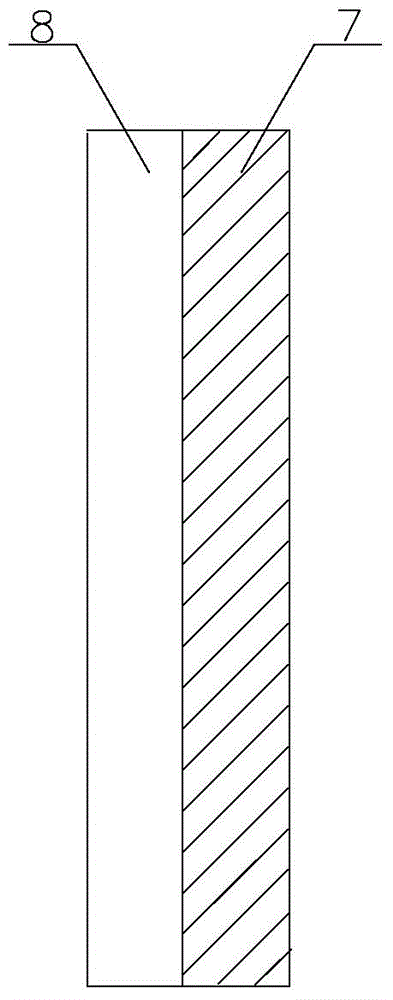

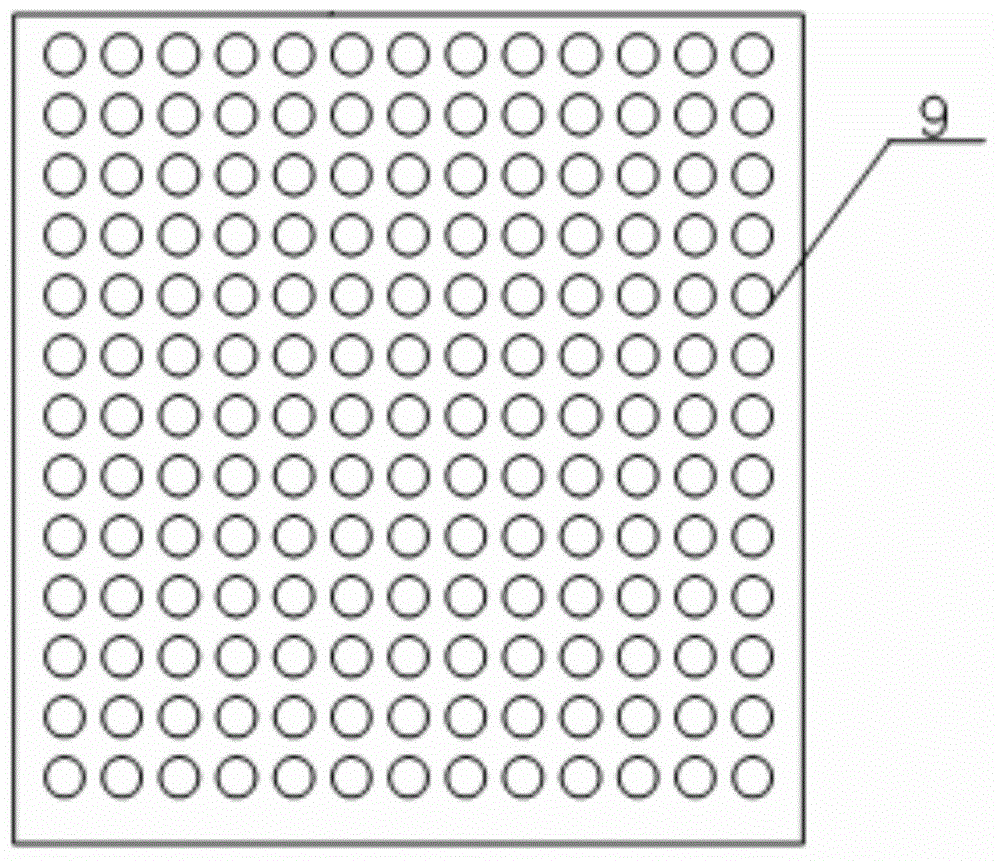

[0019] Specific implementation mode one: combine figure 1 , figure 2 As shown, the present embodiment is a device for microalgae adherent culture and liquid immersion culture conversion, which includes a concentrator 1, a connecting pipe 2, a drip irrigation pipe 3, a groove plate 4, a rotatable support 5, and a collection box 6 ; The placement direction of the grooved plate 4 is at an angle of 5-15° with the horizontal plane; 8. The upper surface of the flexible liquid-permeable material plate 7 has protruding structural units 9 on the surface, and the rows extending in the transverse direction and the columns extending in the longitudinal direction constitute an array of structural units; the transverse of the structural units 9 The cross-section is circular, square, rectangular, elliptical, triangular or rhombus; the structural units 9 are arranged at equal intervals in the same row or the spacing is increased successively; the row spacing between adjacent rows of the str...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentrated algae liquid flows out from the outlet of the concentrator 1, and the operating pressure of the concentrator 1 is 0.10-0.20 MPa. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the drip irrigation pipe 3 is responsible for spreading the algae liquid on the upper surface of the groove plate 4, so as to realize the liquid submerged culture state to the adherent type The transition of the cultivation state, the nominal diameter of the drip irrigation pipe 3 is 12-16mm. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com