A single horizontal well solvent-assisted production method

A production method and horizontal well technology, which is applied in the field of oil reservoir production and single horizontal well solvent-assisted production, can solve the problems of large well spacing fluctuations, affecting development results, consuming large amounts of water and heat, etc., to improve oil production rate and connectivity The effect of speed, ease of drilling and completion, and accelerated oil recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

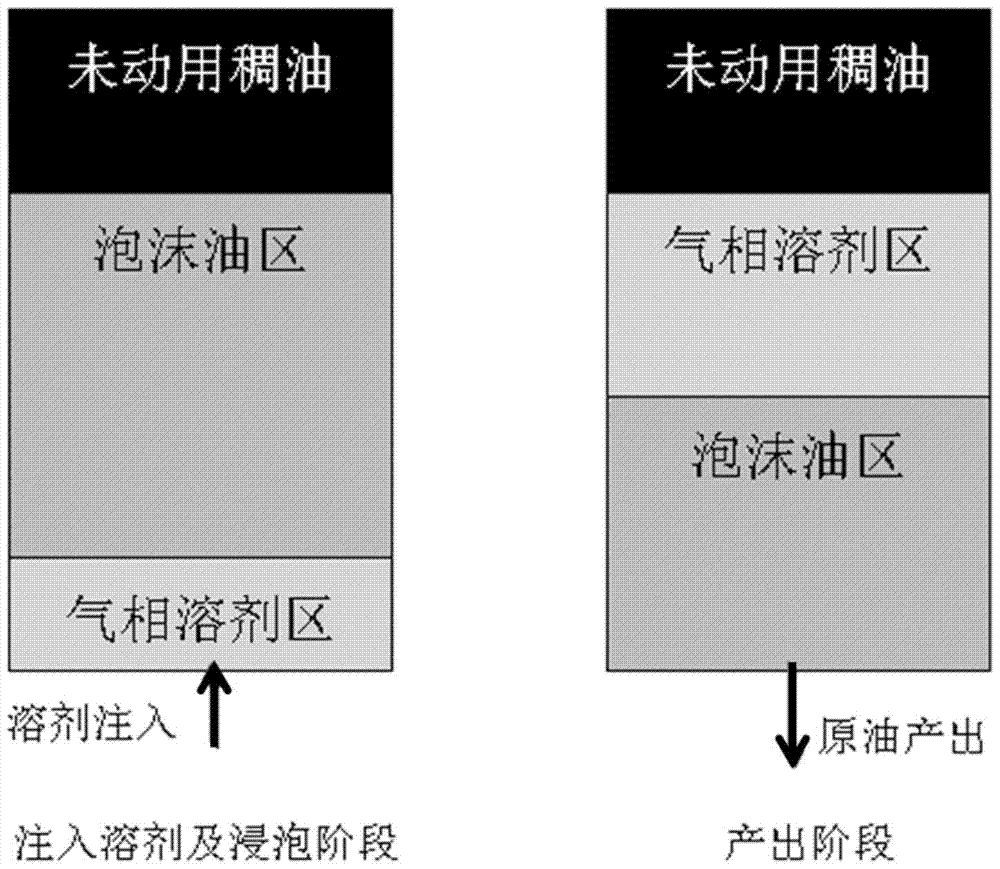

[0043] This embodiment provides a single horizontal well solvent-assisted production method, which specifically includes the following steps:

[0044] Reservoir and production conditions:

[0045] The reservoir depth is 250 meters, the effective reservoir height is 10 meters, the reservoir porosity is 30%, the permeability is 5 Darcy, the viscosity of degassed crude oil at 50 °C is 50000 mPa·S, and the formation temperature is 22 °C. The horizontal well is located 1 meter above the bottom of the reservoir. The horizontal section is 400 meters long, the well spacing is 70 meters, and the borehole diameter is 8.5 inches. 7in slotted screens are used to complete wells to prevent sand-carrying production in horizontal wells. Run long and short oil pipes in the screen pipe, and the diameter of the oil pipes is 27 / 8in. Wherein, the end of the short pipe is connected with a rod pump, and the end of the long pipe is 5-10 meters away from the toe of the horizontal well. In addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com