Alarm device for monitoring partial overtemperature of kiln nozzle

An alarm device and kiln technology, which is applied to furnaces, furnace components, lighting and heating equipment, etc., can solve problems such as burnout temperature resistance, difficulty in automatic monitoring, and difficulty in designing supporting monitoring devices, so as to prevent equipment damage and reduce Effects of maintenance difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

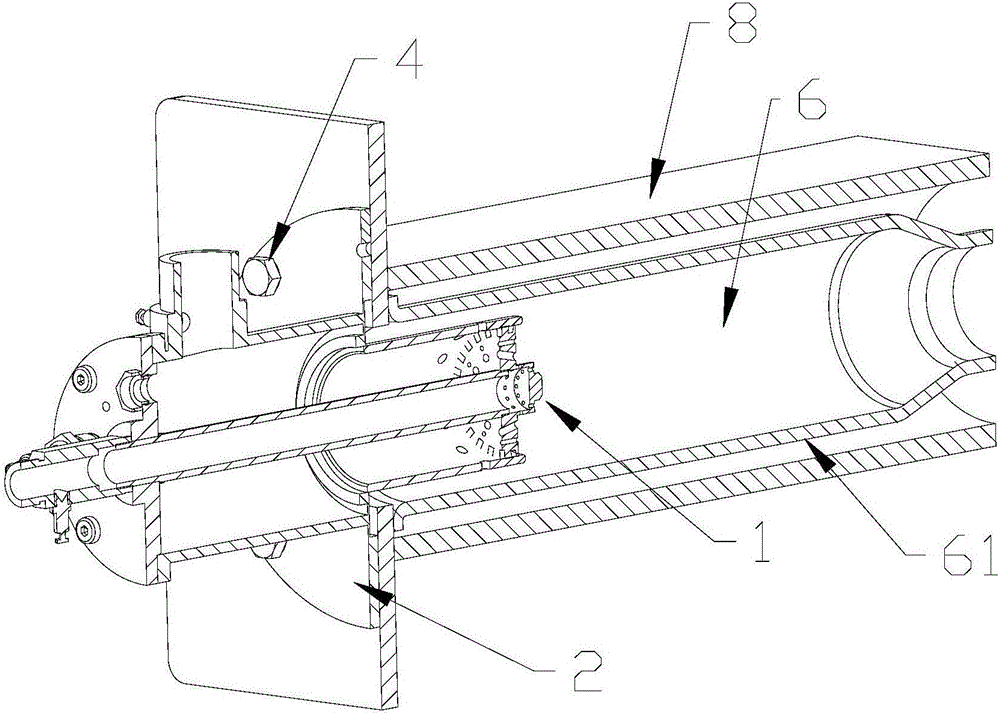

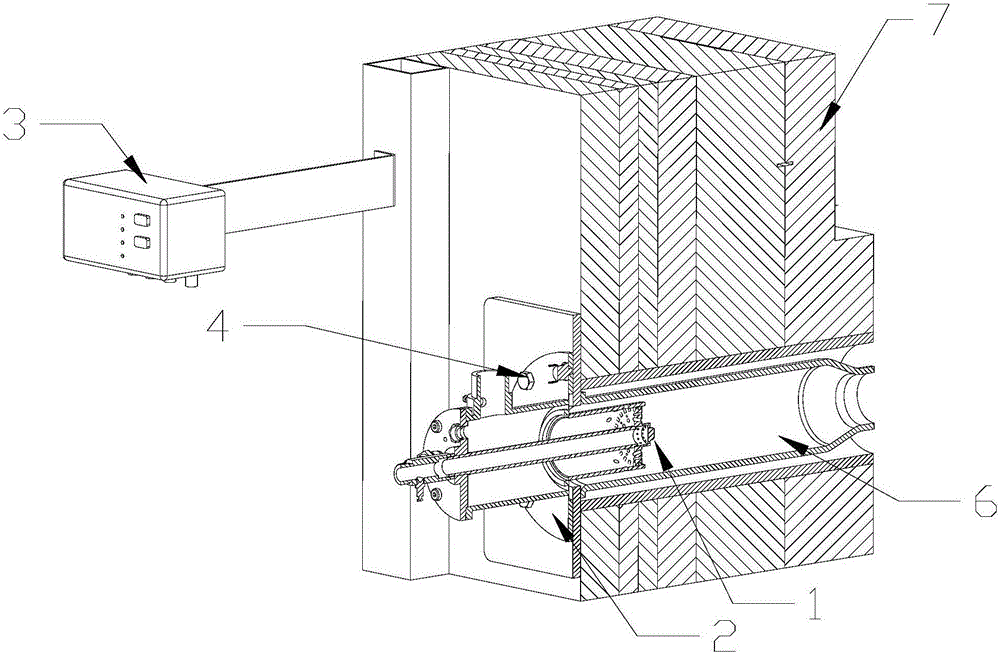

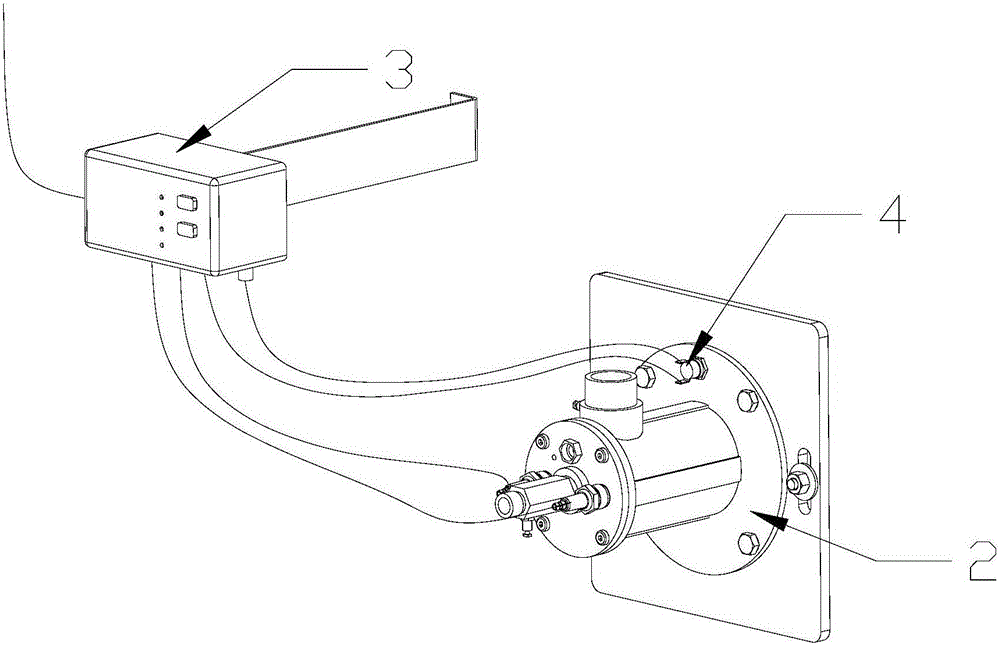

[0015] Such as Figure 1-Figure 4 As shown, a local overtemperature alarm device for monitoring kiln burners according to an embodiment of the present invention

[0016] It includes a burner 1, a burner flange 2, a burner controller 3, and a temperature sensing element 4; among them, the burner 1 has an ignition electrode and a monitoring electrode, and the burner flange 2 is installed on the kiln 5 and is close to the burning On the outer wall, a burner combustion chamber 6 is arranged around the burner 1, and the burner combustion chamber 6 is composed of a pipe sleeve 61 made of silicon carbide, and an insulating layer installed on the kiln 5 is also provided outside the pipe sleeve 61 made of silicon carbide The high aluminum protective cover 8 in 7; the temperature sensing element 4 is a contact temperature sensing element installed on the burner flange 2, and transmits the temperature signal to the burner controller 3. The burner controller 3 is used to control ignition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com