A method for joint production of synthesis gas based on slurry gasification and natural gas conversion

A technology of joint preparation and synthesis gas, applied in the field of coal chemical industry, can solve the problems of large emissions, waste of resources, power, and high H2 content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

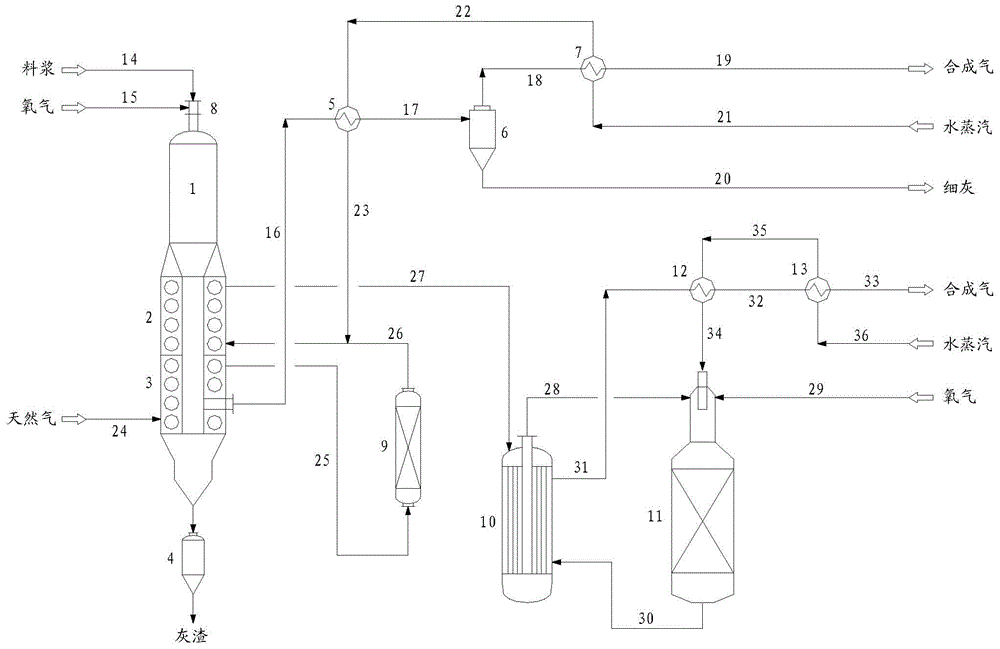

[0084] Embodiment 1: The present invention is based on slurry gasification and natural gas conversion to jointly prepare synthesis gas

[0085] The composition of coal used in this example is listed in Table 1, and the composition of natural gas (by volume on a dry basis) is listed in Table 2.

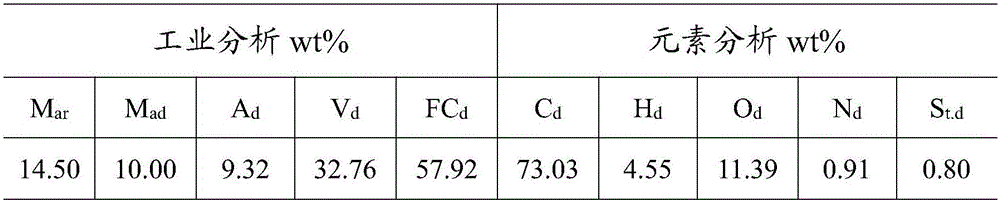

[0086] Table 1: Composition of Raw Coal

[0087]

[0088] Table 2: Dry Basis Composition of Natural Gas, by Total Volume

[0089]

[0090] According to this specification, this embodiment figure 1 The described process flow is carried out.

[0091] The specific implementation steps are as follows:

[0092] Raw coal with a moisture content of 10% is about 25010.66kg / h, and water and a small amount of additives (highly polymerized sodium naphthalene sulfonate) are used to make a slurry with a concentration of 60% by weight of dry coal, and the flow rate of the slurry is about 37515.98kg / h , the slurry is sent to the nozzle 8 through the slurry pipeline 14, and the flow rate th...

Embodiment 2

[0103] Embodiment 2: The present invention is based on slurry gasification and natural gas conversion to jointly prepare synthesis gas

[0104] The present invention is carried out with a local coal as the main raw material. The raw coal analysis data is listed in Table 3, and the dry basis composition of natural gas is listed in Table 4.

[0105] Table 3: Composition of Raw Coal

[0106]

[0107] Table 4: Dry Basis Composition of Natural Gas, by Total Volume

[0108] Element CH 4

C 2 h 6

C 3 h 8

N 2

h 2 S

volumevol% 95.0% 1.0% 0.9% 3.0% trace

[0109] The specific implementation steps of this embodiment are the same as those of Example 1, except that the raw coal in a certain place is 13291.9kg / h, and water and a small amount of additive (highly polymerized sodium naphthalenesulfonate) are used to make a material with a concentration of 56% and a flow rate of 20623.8kg / h. Slurry, oxygen flow rate 12237.2Nm 3 / h, t...

Embodiment 3

[0114] Embodiment 3: The present invention jointly prepares synthesis gas on the basis of slurry gasification and natural gas conversion

[0115] The present invention is implemented with coal from a certain place as the main raw material. The raw coal analysis data is listed in Table 5, and the dry basis composition of natural gas is listed in Table 6.

[0116] Table 5: Composition of Raw Coal

[0117]

[0118] Table 6: Dry Basis Composition of Natural Gas, by Total Volume

[0119]

[0120] The specific implementation steps of this embodiment are the same as those in Example 1. The raw coal in a certain place is about 14503.07kg / h, and water and a small amount of additive (highly polymerized sodium naphthalene sulfonate) are used to make a concentration of about 57%, and a flow rate of 25443.99kg / h slurry, oxygen flow rate 8628.82Nm 3 / h, the slurry and oxygen are sprayed into the gasification furnace 1 through the nozzle 8, the gasification reaction pressure is 4.2MP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com