Anti-freezing concrete preparation method by using mine tailings as aggregate

A technology for antifreeze concrete and tailings aggregates, which is applied in the field of building materials, can solve the problems of prolonged construction operation time in winter, poor antifreeze performance, large discharge of tailings waste, etc., so as to prolong construction operation time in winter and solve condensation problems Long time, the effect of resolving the increasing tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

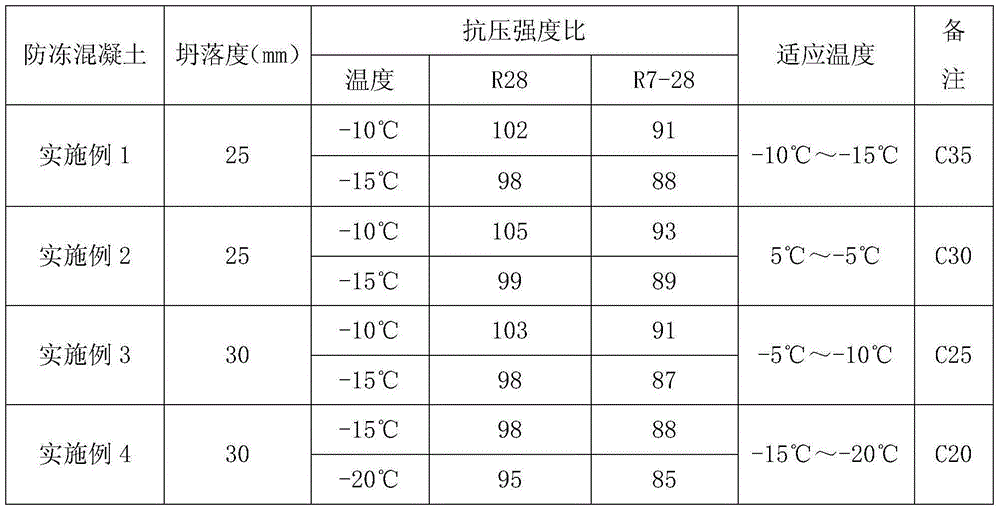

Embodiment 1

[0022] C35 antifreeze concrete, suitable temperature: -10℃~-15℃, component formula by weight ratio: cement 24.8, tailings powder 16, tailings aggregate 35, grade III fly ash 10, water 10, tailings modified Agent 2.9 and sodium nitrite antifreeze 1.3.

[0023] Among them, the cement is slag portland cement, grade 42.5.

[0024] The tailings modifier is made of naphthalene-based powder water reducer, alum expansion agent expansion agent, cellulose ether, diatomaceous earth, zeolite powder, and latex powder in a ratio of 1.5:1.5:2:1:1:1. A composite admixture with high water-reducing, plastic-retaining and stimulating properties; the cellulose ether is methyl cellulose ether.

[0025] The tailings powder is the waste produced during the production of concentrate powder, and its particle size ≥ 280um accounts for 6%, 100um

[0026] The tailings aggregate is p...

Embodiment 2

[0032] C30 antifreeze concrete, suitable temperature: 5℃~-5℃, component formula by weight ratio: cement 24, tailings powder 17, tailings aggregate 35, grade III fly ash 10, water 10, tailings modifier 2.95, sodium nitrite antifreeze 1.05.

[0033] Among them, the cement is Portland cement, grade 42.5.

[0034] The tailings modifier is prepared from polyhydroxy acid powder water reducer, iron filings expansion agent, cellulose ether, diatomaceous earth, zeolite powder, latex powder according to the ratio of 1.5:1.5:2:1:1:1 It is a composite admixture with high water reduction, plastic retention and excitation properties; cellulose ether is methyl cellulose ether.

Embodiment 3

[0036] C25 antifreeze concrete, suitable temperature: -5℃~-10℃, component formula by weight ratio: cement 22.85, tailings powder 17, tailings aggregate 36, grade III fly ash 10, water 11, tailings modification Agent 2 and sodium nitrite antifreeze 1.15.

[0037] Among them, the cement is fly ash portland cement, grade 42.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com