Rare earth modified medical stone powder with conductivity and preparation method thereof

A technology of rare earth modification and medical stone powder, which is applied in the field of rare earth modified medical stone conductive powder materials and its preparation, can solve problems such as cost, processing difficulty, and application restrictions, and achieve high cost performance, strong market competitiveness, and eliminate Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

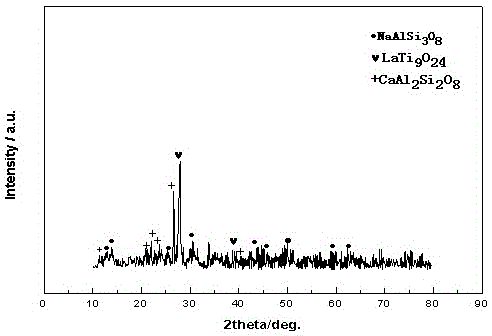

[0026] After the infiltration furnace is heated up to 700°C, drop methanol into the furnace for 10 minutes to remove the air in the furnace; then place the medical stone powder in the infiltration furnace; drop it into the furnace at a rate of 60 drops per minute Add 5wt.% La element-containing expansion solution for 5 hours to obtain medical stone powder conductive powder, and its room temperature resistivity is 4.0×10 4 Ω m, X-ray diffraction (XRD) spectrum as figure 1 shown. from figure 1 It can be seen that the rare earth elements have penetrated into the medical stone powder, and chemically reacted with the constituents of the medical stone to form LaTi 9 o 24 And other new compounds containing rare earth elements lead to significant enhancement of electrical conductivity of medical stone powder.

Embodiment 2

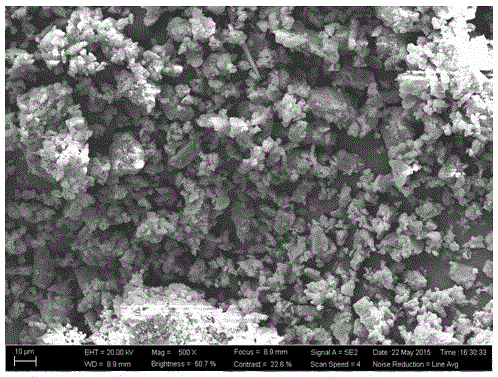

[0028] After the infiltration furnace is heated up to 700°C, drop methanol into the furnace for 10 minutes to remove the air in the furnace; then place the medical stone powder in the infiltration furnace; drop it into the furnace at a rate of 80 drops per minute Dropping 4wt.% Er-containing expansion solution for 4 hours, the medical stone powder conductive powder can be obtained, and its room temperature resistivity is 7.2×10 4 Ω m, the scanning electron microscope (SEM) image of the obtained powder is shown in figure 2 shown. from figure 2 It can be seen from the figure that the powder particles are fine and the pores are obvious. According to energy spectrum (EDS) analysis, the content of Er in rare earth modified medical stone conductive powder is 9.69 wt.%.

Embodiment 3

[0030] After the infiltration furnace is heated to 650°C, drop methanol into the furnace for 10 minutes to remove the air in the furnace; then place the medical stone powder in the infiltration furnace; drip into the furnace at a rate of 60 drops per minute Add 5wt.% Ce-containing infiltration solution for 5 hours to obtain medical stone powder conductive powder, and its room temperature resistivity is 1.2×10 4 Ω·m. Its appearance is similar to figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature resistivity | aaaaa | aaaaa |

| Room temperature resistivity | aaaaa | aaaaa |

| Room temperature resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com