Process for wholly recycling valuable metals in waste SCR denitration catalysts through wet method

A technology for denitrification catalysts and valuable metals, which is applied in the field of overall wet recovery of valuable metals in invalid SCR denitrification catalysts, can solve the problems of wasting costs, occupying land resources, etc., and achieve the effect of reducing resource waste and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

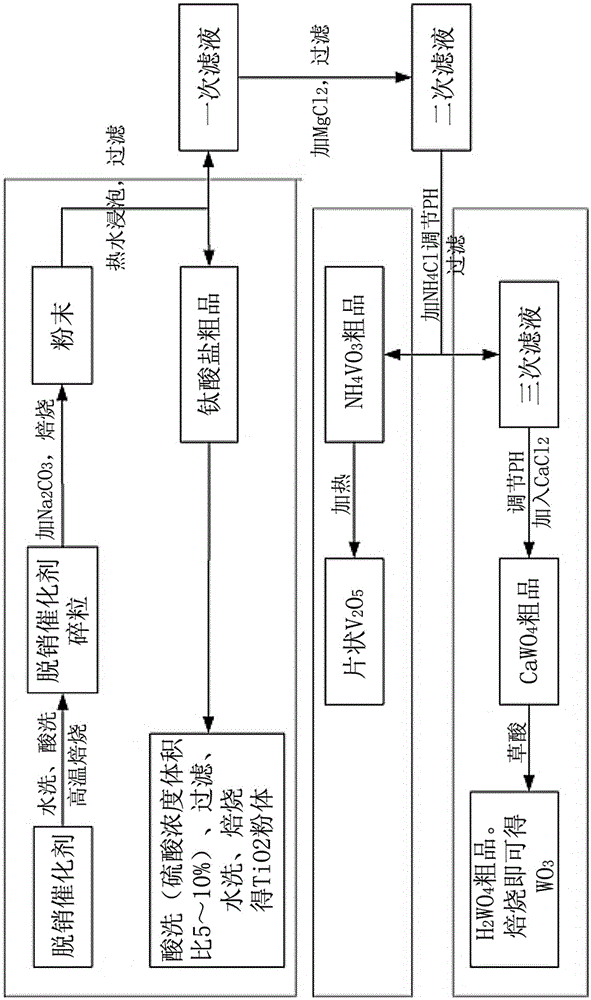

[0040] Such as figure 1 Shown: In this embodiment, valuable metals are recovered from the spent SCR denitration catalyst, and the whole wet process is adopted, and the process is carried out according to the following steps.

[0041] Removal of heavy metal impurities: the spent SCR denitrification catalyst was put into 5% hydrochloric acid for pickling, deionized water washing, and then roasted at 600°C for 3 hours in a tunnel kiln to remove Hg, As and organic substances that may be adsorbed on the surface. Impurities.

[0042] Sodiumization and crushing: adding Na to the spent SCR denitrification catalyst after removing heavy metal impurities 2 CO 3 , Na 2 CO 3 With the exhausted SCR denitration catalyst (with TiO 2 The molar ratio of the mixture is 2:1. After being fully mixed by a mixer, it is roasted in a tunnel kiln at 650°C for 3 hours, and then put into a crusher for crushing and grinding to 100 mesh to obtain a mixed powder.

[0043] Separation and filtration: So...

Embodiment 2

[0048] Such as figure 1 Shown: In this embodiment, valuable metals are recovered from the spent SCR denitration catalyst, and the whole wet process is adopted, and the process is carried out according to the following steps.

[0049] Removal of heavy metal impurities: put the spent SCR denitrification catalyst into 7% hydrochloric acid for pickling, washing with deionized water, and then roasting at 600°C for 3 hours in a tunnel kiln to remove Hg, As and organic substances that may be adsorbed on the surface. Impurities.

[0050] Sodiumization and crushing: adding Na to the spent SCR denitrification catalyst after removing heavy metal impurities 2 CO 3 , Na 2 CO 3 With the exhausted SCR denitration catalyst (with TiO 2 The molar ratio of the powder is 2.5:1. After being fully mixed by a mixer, it is roasted in a tunnel kiln at 650°C for 4 hours, and then put into a crusher for crushing and grinding to 100 mesh to obtain a mixed powder.

[0051] Separation and filtration:...

Embodiment 3

[0056] Such as figure 1 Shown: In this embodiment, valuable metals are recovered from the spent SCR denitration catalyst, and the whole wet process is adopted, and the process is carried out according to the following steps.

[0057] Removal of heavy metal impurities: The spent SCR denitrification catalyst was put into 9% hydrochloric acid for pickling, deionized water washing, and then roasted at 600°C for 3 hours in a tunnel kiln to remove Hg, As and organic substances that may be adsorbed on the surface. Impurities.

[0058] Sodiumization and crushing: adding Na to the spent SCR denitrification catalyst after removing heavy metal impurities 2 CO 3 , Na 2 CO 3 With the exhausted SCR denitration catalyst (with TiO 2 The molar ratio of the mixture is 3:1. After being fully mixed by a mixer, it is roasted in a tunnel kiln at 650°C for 5 hours, and then put into a crusher for crushing and grinding to 100 mesh to obtain a mixed powder.

[0059] Separation and filtration: so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com