Premixed auxiliary material for preparing orally disintegrating tablet through direct compression

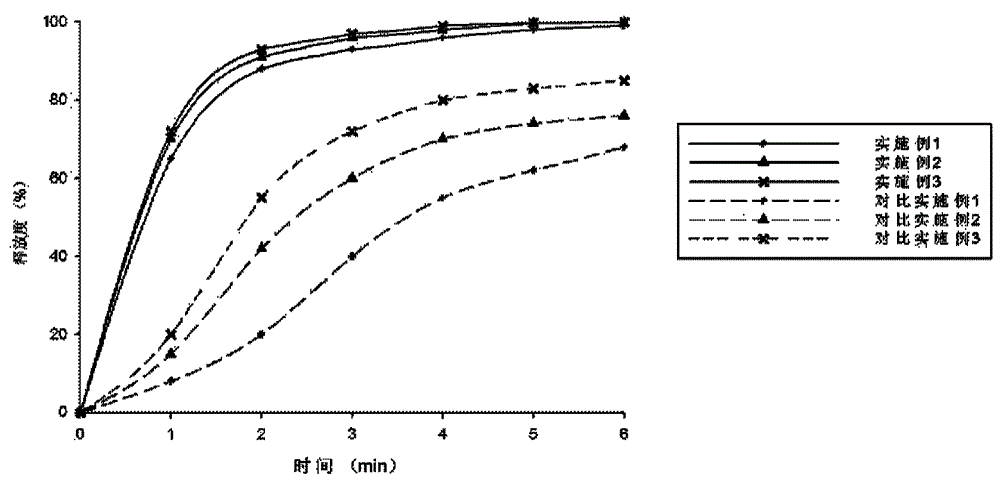

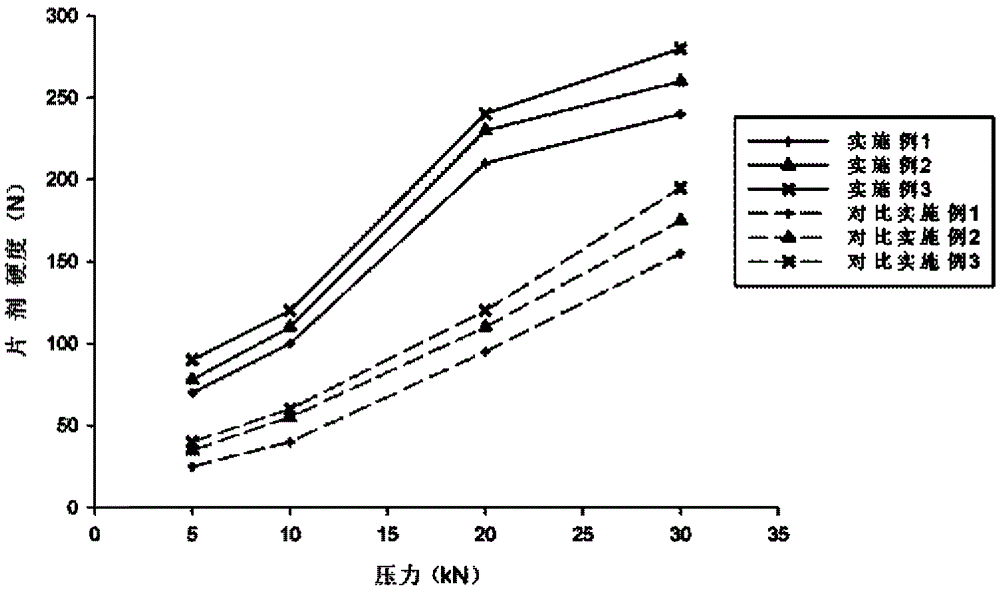

A technology of premixing excipients and tableting, which is applied in the field of biomedicine, can solve the problems of unsatisfactory excipient performance indicators and complicated steps, and achieve the effects of high tablet hardness, increased release rate, and improved compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0031] Table 1. Composition ratios in Examples 1-3

[0032]

[0033] According to the proportion of each component in the above table, mix each auxiliary material evenly, set the temperature from each section of the twin-screw extruder to the machine head in order of 200°C→400°C→400°C→400°C→300°C, and the screw speed is 40 r / min, the uniformly mixed material is put into the hopper, and extruded in the shape of strips from the die hole of the machine head after extrusion. The extrudate was placed in an aluminum pan, cooled at room temperature, and crushed. Pass through 80-100 mesh pharmacopoeia sieves to prepare the premixed auxiliary material compound and set aside. Mix the premixed auxiliary materials and vitamin C uniformly at a weight ratio of 4:1, and directly compress the tablet with different pressures to obtain finished vitamin C orally disintegrating tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com