Light and heavy phase alternate feeding countercurrent extraction process

A technology of alternate feeding and extraction, applied in the direction of liquid solution solvent extraction, etc., can solve the problems of back mixing, reduce mass transfer efficiency, and generate liquid flooding, and achieve the effect of suppressing back mixing effect, improving extraction efficiency, and small retention fraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

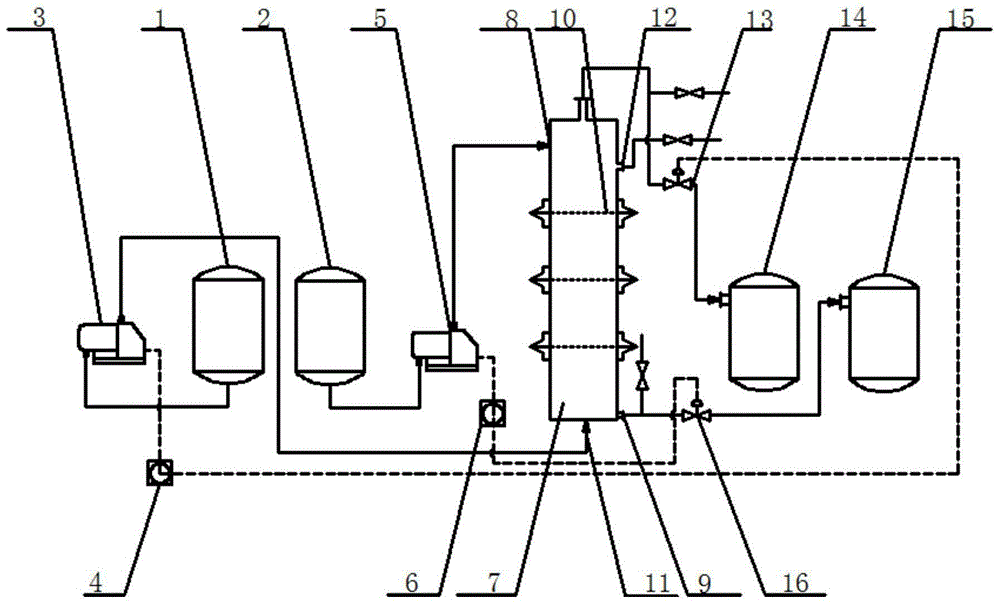

[0035] The liquid-liquid system to be separated in this embodiment is a kerosene-water system, water is the continuous phase, and benzoic acid is extracted from kerosene into water as a solute.

[0036] In this embodiment, there are three stages of sieve trays in the extraction tower 7, the aperture of each stage of sieve trays 10 is 0.50mm, the hole spacing is 2.50mm, and the height of the extraction stage of the extraction tower is 5cm.

[0037] First through the preparatory stage, after the continuous phase is full of the extraction tower, the first feed pump 3 communicated with the dispersed phase storage tank 1 is opened, and the first electric valve 13 communicated with the raffinate phase storage tank 14 is passed into the dispersed phase, dispersed The flow rate of phase is 873.53kg / m 2 / h, while the dispersed phase is fed, the raffinate is discharged through the dispersed phase outlet 12 positioned at the top of the extraction tower 7, stored in the raffinate phase st...

Embodiment 2

[0044] The liquid-liquid system to be separated in this embodiment is ethyl acetate-water system, water is the continuous phase, and ethanol is extracted from ethyl acetate into water as a solute.

[0045] In this embodiment, there are five stages of sieve trays 10 in the extraction tower 7, the aperture of each stage of the sieve trays 10 is 2.0 mm, the hole spacing is 5.0 mm, and the height of the extraction stage of the extraction tower is 5 cm.

[0046] After first passing through the preparation stage, open the first feed pump 3 communicated with the dispersed phase storage tank 1, and the first electric valve 13 communicated with the raffinate phase storage tank 14 leads to the dispersed phase, and the flow rate of the dispersed phase is 15465.52kg / m 2 / h, while the dispersed phase is fed, the raffinate is discharged through the dispersed phase discharge port 12 positioned at the top of the extraction tower 7, stored in the raffinate phase storage tank 14, and the first...

Embodiment 3

[0053] The liquid-liquid system to be separated in this embodiment is ethyl acetate-water system, water is the continuous phase, and ethanol is extracted from ethyl acetate into water as a solute.

[0054] In this embodiment, there are five stages of sieve trays 10 in the extraction tower 7, the aperture of each stage of the sieve trays 10 is 2.0 mm, the hole spacing is 5.0 mm, and the height of the extraction stage of the extraction tower is 5 cm.

[0055] After first passing through the preparation stage, open the first feed pump 3 communicated with the dispersed phase storage tank 1, and the first electric valve 13 communicated with the raffinate phase storage tank 14 leads to the dispersed phase, and the flow rate of the dispersed phase is 5207kg / m 2 / h, while the dispersed phase is fed, the raffinate is discharged through the dispersed phase discharge port 12 positioned at the top of the extraction tower 7, stored in the raffinate phase storage tank 14, and the first feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com