A microwave reactor and its application

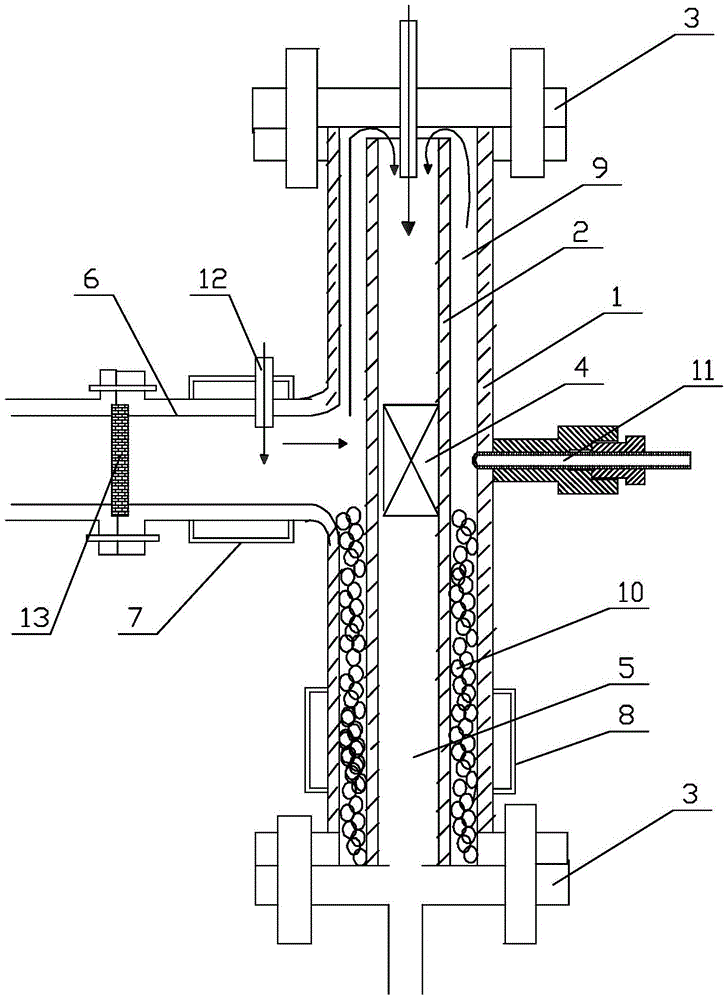

A microwave reactor and reactor technology, which is applied in the chemical/physical/physical-chemical process of applying energy, refining to remove heteroatoms, etc., can solve the problem that microwave reactors cannot withstand high temperature and high pressure, and achieve high pressure reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

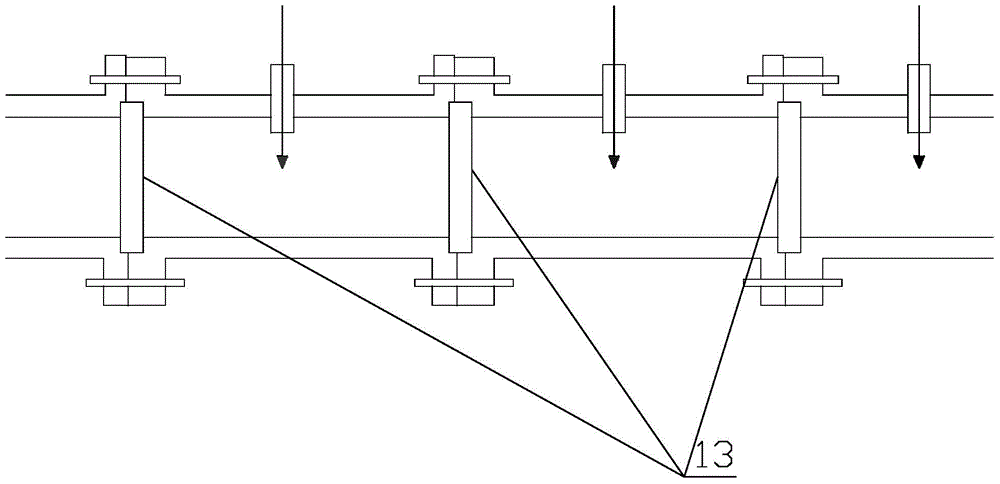

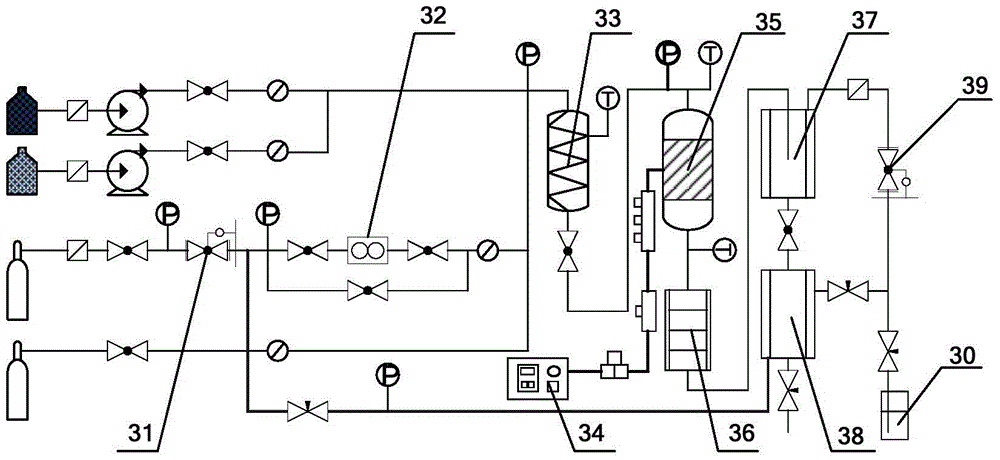

Method used

Image

Examples

Embodiment 1

[0031] The FCC gasoline raw material is subjected to hydrodesulfurization treatment with the hydrodesulfurization device of the present invention. The total sulfur content of the FCC gasoline feedstock used in the experiment was 450 ppm, and the hydrocarbons consisted of n-alkanes ( n -P), isoparaffins ( i -P), olefins (O), naphthenes (N) and aromatics (A) are: 5.41%, 37.59%, 27.15%, 7.84% and 22.01%, respectively, motor octane number (MON) It is 87.79 and has a Research Octane Number (RON) of 94.75. The catalyst uses conventional Ni-Mo / Al 2 o 3 .

[0032] Adopt the used device of the present invention to carry out FCC gasoline hydrogenation desulfurization research, be 2 MPa at pressure, the weight hourly space velocity is 2h -1 , the volume ratio of hydrogen to oil was 200:1, and the microwave power was 1.6 kW, the effect of different reaction temperatures (240-280 ℃) on the hydrodesulfurization reaction of FCC gasoline under the action of microwave was investigated, an...

Embodiment 2

[0034] Using the reactor of the present invention to study the hydrodesulfurization of catalytic cracking diesel oil, the properties of the diesel oil are: the sulfur content is 1576ppm, the nitrogen content is 650ppm, the initial boiling point of the diesel oil is 190°C, and the final boiling point is 375°C. Using the above microwave device and conventional Ni-Mo / Al 2 o 3 The reaction is carried out under the catalyst, the microwave power is 3.5kW, the reaction pressure is 6MPa, the hydrogen-oil ratio is 600:1, and the space velocity is 1h -1 , when the reaction temperature was 330°C, 350°C and 360°C, the removal rates of diesel oil reached 86%, 93% and 97%, which were 10-13% higher than those under conventional conditions; the hydrogenation denitrogenation rates reached 71%, 83% respectively. % and 89%, 15-17% higher than the denitrification rate of conventional heating under the same conditions.

[0035] Among them, in terms of safety control, an overpressure parking auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com