Method and system for producing hydrogen oil by converting ultrahigh-temperature fly ash

An ultra-high temperature, fly ash technology, applied in the field of hydrogen energy, can solve the problems of the large-scale application of normal temperature and pressure liquid organic hydrogen storage technology, poisoning fuel cells, poisoning fuel cells, etc., to reduce the risk of entering the external environment, reduce Effects of storage and transport costs, good environmental protection and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

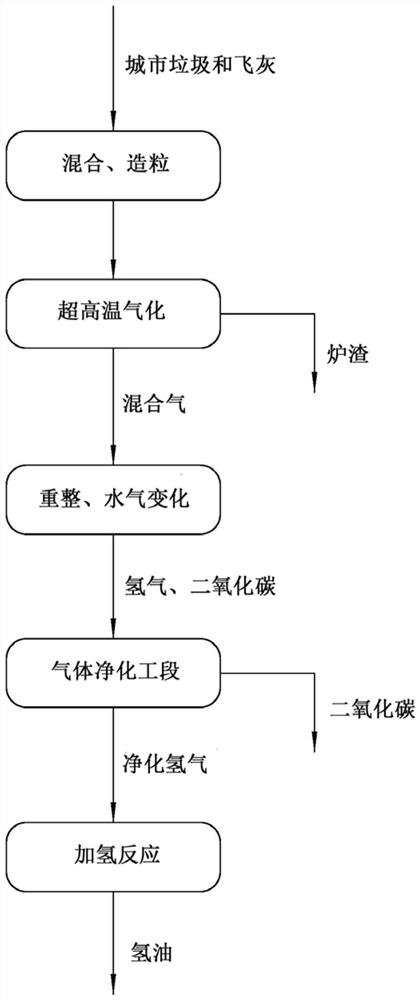

[0038] as Figure 1 The flowchart of the ultra-high temperature fly ash conversion method for hydrogen oil shown, the fly ash is first mixed with the municipal garbage in proportion, and then the granulation is formed. The mixed mass ratio of fly ash to municipal waste is 1:7. The granulation molding process reduces the secondary entrainment of fly ash.

[0039] The granulated mixture is gasified at ultra-high temperatures to generate molten slag and mixtures. The gasification temperature is 1600 °C. In the ultra-high temperature gasification process, high calorific value substances are supplemented to reduce the consumption of fly ash and municipal waste itself.

[0040] Under the action of a highly selective reaction catalyst, the mixture first undergoes a reforming reaction to generate crude syngas, and then hydrogen and carbon dioxide are prepared by the water-gas transformation reaction. Crude syngas include CO, H 2 、CO 2 。 The highly selective reaction catalyst is a supported...

Embodiment 2

[0055] The fly ash is first mixed proportionally with the municipal waste, and then the granulation is formed. The mixed mass ratio of fly ash to municipal waste is 1:8. The granulation molding process reduces the secondary entrainment of fly ash.

[0056] The granulated mixture is gasified at ultra-high temperatures to generate molten slag and mixtures. The gasification temperature is 1300°C. In the ultra-high temperature gasification process, high calorific value substances are supplemented to reduce the consumption of fly ash and municipal waste itself.

[0057] Under the action of a highly selective reaction catalyst, the mixture first undergoes a reforming reaction to generate crude syngas, and then hydrogen and carbon dioxide are prepared by the water-gas transformation reaction. Crude syngas include CO, H 2 、CO 2 。 The highly selective reaction catalyst is a supported catalyst, the active component is FeS, and the support is activated carbon.

[0058] Hydrogen is purified t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com