Method and system for producing hydrogen oil through waste pyrolysis

A waste and pyrolysis technology, applied in the field of hydrogen energy, can solve the problems of large-scale application of normal temperature and pressure liquid organic hydrogen storage technology, poisoning fuel cells, poisoning fuel cells, etc., achieving good environmental protection and economic value, and improving utilization. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

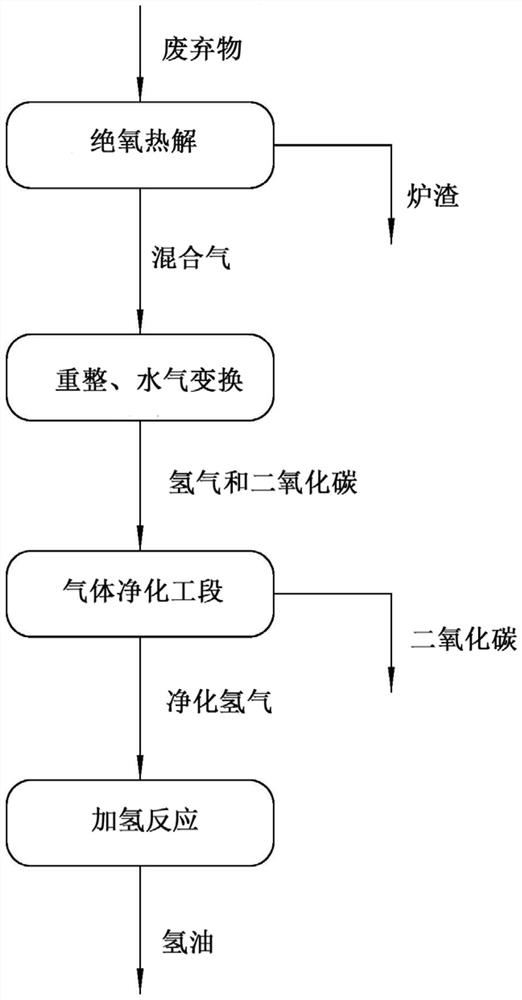

[0036] figure 1 It is a flow chart of the method for producing hydrogen oil by pyrolysis of waste. Firstly, the waste is subjected to anaerobic pyrolysis to generate carbonized slag and mixed gas. The anaerobic pyrolysis temperature is 600°C. The waste is domestic garbage, industrial solid waste or biomass.

[0037] The mixed gas undergoes a reforming reaction under the action of a highly selective reaction catalyst to generate crude synthesis gas, and then undergoes a water-gas shift reaction to obtain hydrogen and carbon dioxide. The water gas shift reaction temperature is 600°C. The highly selective reaction catalyst is a supported catalyst, the active component is a mixture of Ni and Mn, and the carrier is activated carbon.

[0038]The hydrogen passes through the gas purification process to obtain purified hydrogen, and the purity of the purified hydrogen is 75%. The gas purification process includes desulfurization process, denitrification process and periodic purging...

Embodiment 2

[0047] First, the waste is subjected to anaerobic pyrolysis to generate carbonized slag and mixed gas. The anaerobic pyrolysis temperature is 800°C.

[0048] The mixed gas undergoes a reforming reaction under the action of a highly selective reaction catalyst to generate crude synthesis gas, and then undergoes a water-gas shift reaction to obtain hydrogen and carbon dioxide. The water gas shift reaction temperature is 500°C. The highly selective reaction catalyst is a supported catalyst, and the active component is Co 2 o 3 , the carrier is SiO 2 .

[0049] The hydrogen passes through the gas purification process to obtain purified hydrogen, and the purity of the purified hydrogen is 85%. The gas purification process includes desulfurization process, denitrification process and periodic purging process. The periodic purging process is to vent the impurities in the gas, and a purging process is carried out after every 1 to 10 desulfurization processes and denitrification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com