Preparation methods for bifunctional catalyst and low-carbon-chain olefin

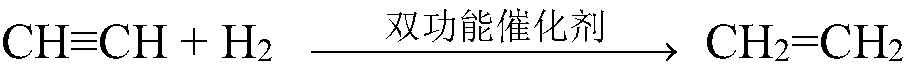

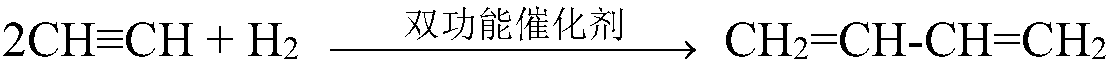

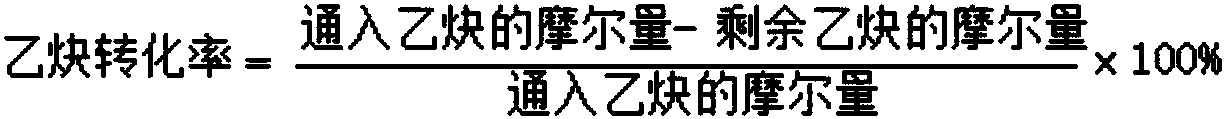

A dual-functional catalyst and co-catalyst technology, applied in the direction of catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of catalyst pore blockage, catalyst deactivation, high reduction temperature, etc., and achieve low cost and high selectivity High, high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing a bifunctional catalyst disclosed in an embodiment of the present invention comprises:

[0036] Step 1 prepares the SAPO-34 molecular sieve carrier with multi-level channels:

[0037] Step 11 prepares initial gel mixture; Wherein, the preparation of step 11 may comprise:

[0038] Step 111: Mix the aqueous solutions of the aluminum source and the phosphorus source, and stir at room temperature for 1 to 3 hours to obtain a mixture solution;

[0039] Step 112 Add silicon source, organic amine and hydrofluoric acid solution into the mixture solution, stir evenly, and stir at 50-70°C for 10-30 minutes to obtain the initial gel mixture; on the one hand, temperature control is to accelerate the dissolution of organic Amine templating agents, on the other hand, promote the formation of gel-like mixtures. If the temperature is too low, the stirring time needs to be increased; if the temperature is too high, the viscosity of the obtained gel-like mixture ...

Embodiment 1

[0063] (1) Synthesis of the carrier SAPO-34 with hierarchical channels. According to SiO 2 :Al 2 o 3 :P 2 o 5 : organic amine: hydrofluoric acid: water=0.4:1.0:1.5:3.0:3.0:60; after weighing respectively, carry out according to the following steps:

[0064] 1) Mix the aqueous solutions of the aluminum source and the phosphorus source, and stir at room temperature for 3 hours to obtain a mixture solution.

[0065] 2) Add silicon source, organic amine template and hydrofluoric acid solution into the above mixing system, and stir at 70°C for 30 minutes to obtain an initial gel-like mixture;

[0066] 3) Quickly transfer the initial gel-like mixture to a dynamic kettle with a volume of 200ml, keep stirring, seal it and mix it according to the volume ratio of acetylene and hydrogen at a ratio of 1:5, then pass the mixed gas into the dynamic kettle, repeatedly inflate, Deflate at least 3 times, and finally pressurize the mixture of acetylene and hydrogen to 2MPa, stir in airtig...

Embodiment 2

[0079] The difference with Example 1 is that in the step 3), acetylene and hydrogen volume ratio are mixed in a ratio of 1:10;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com