Multi-piece motor core one-time lamination welding system and method

A welding system and one-time technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of long time consumption and difficult to guarantee accuracy, so as to ensure the quality of products, ensure product quality, and avoid uneven pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

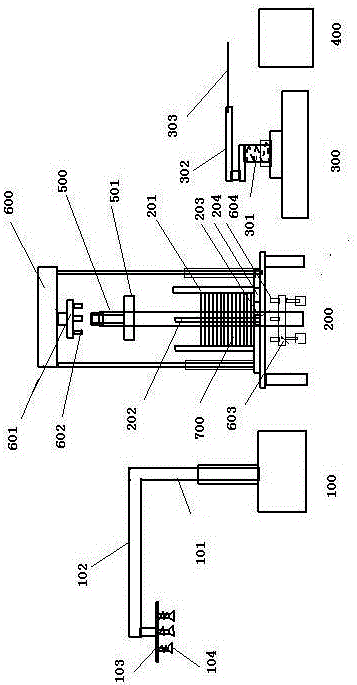

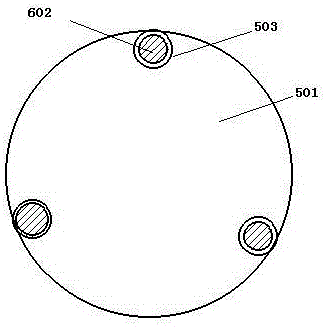

[0018] Refer to the following Figure 1-Figure 2 The technical solution of the present invention is described in detail, the technical solution of the present invention is a one-time lamination welding system for multi-piece motor cores, figure 1 It is a schematic diagram of the structure of the present invention, including a high-voltage arc welding machine 600. Multi-piece motor stator or rotor punches are superimposed and placed on a special stacking mechanism 200. There are positioning gaps on the punching sheet 700. The stacking mechanism 200 includes punching positioning. device, lamination device 500, counter, lamination device 500 is provided with indenter 501, the two ends of stacked punches are provided with a plurality of welding torches 602 and electrode 604 contact positions, and stacking mechanism 200 is provided with a punching-in device 100 and the iron core unloading device 300, the lamination welding system is connected with the controller.

[0019] The pun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com