Thermal battery stack with low internal resistance and preparation method

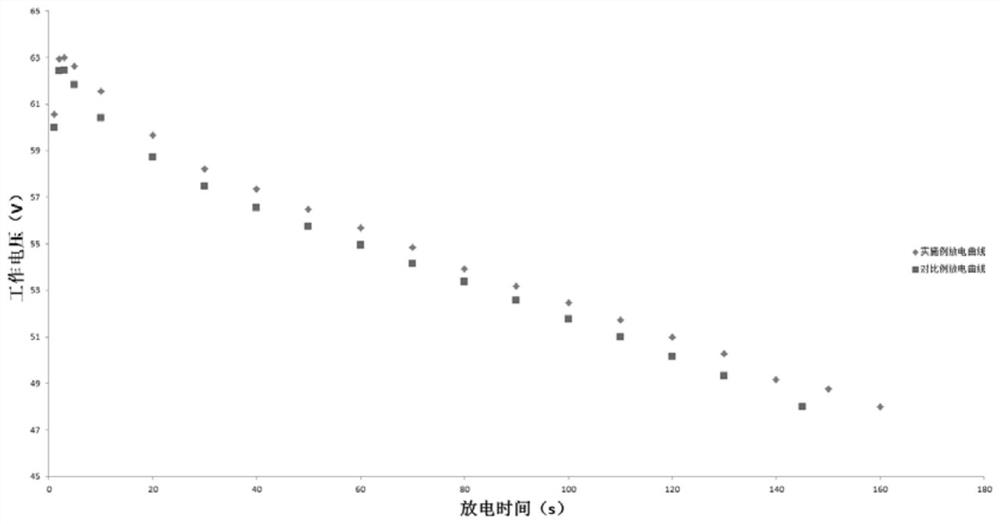

A technology for thermal batteries and battery stacks, which is applied to the components of primary batteries, battery pack components, circuits, etc., can solve the problems of very serious influence of thermal batteries, drop of output voltage of thermal batteries, and failure of thermal batteries to work normally. The effect of reducing assembly time, reducing battery internal resistance, and reducing stacking processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

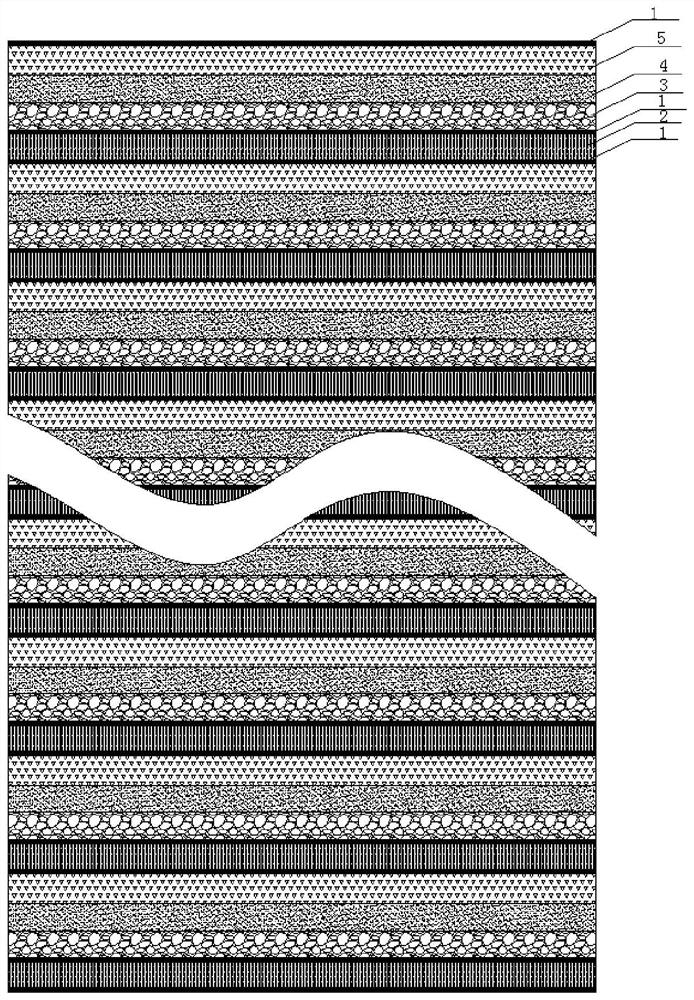

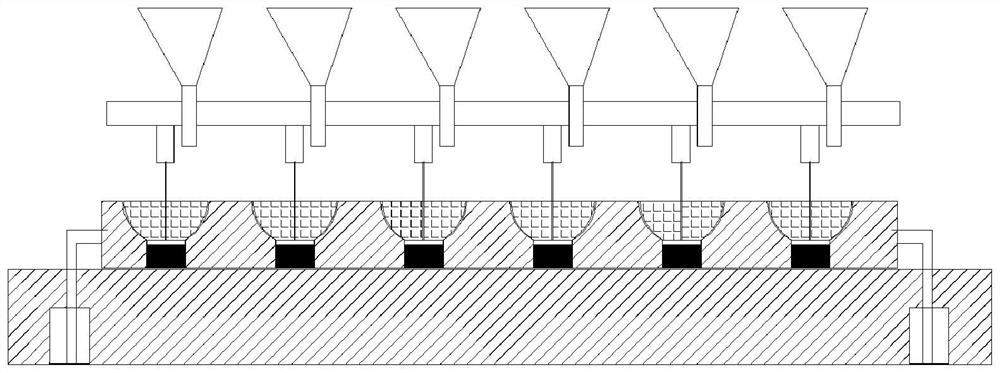

[0020] A method for preparing a low internal resistance thermal battery stack: comprising a plurality of stacked battery cells, the battery cells include sequentially stacked silver powder 1 (conductive spacer powder adopts silver powder 1), heating powder 2, conductive spacer powder 1, negative electrode Powder 3, diaphragm 4 powder and positive electrode powder 5; using figure 2 The integrated mold for rapid powder spreading and demoulding shown is prepared. (1) Silver powder 1 is flattened: Silver powder 1 is weighed and added into the bowl-shaped mold frame through a funnel, and then the bowl-shaped scraper of the automatic powder-feeding and spreading system is The bowl-shaped groove above the mold cavity rotates at a speed of 5r / s. At the same time, the mold frame and the automatic powder spreading system above it rise slowly at a speed of 0.10mm / s, so that the silver powder 1 enters the cylindrical cavity below the mold cavity. The automatic powder spreading system sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com