Salt discharging system and method in Bayer-process aluminium oxide production process

A technology for production process and salt discharge system, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of high requirements for equipment and pipes, high energy consumption, high maintenance costs, and reduce energy consumption, save steam, and reduce usage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

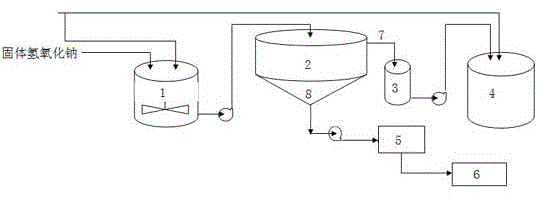

[0023] The salt discharge system of the Bayer method alumina production process of the present invention comprises a strong alkali storage tank 1, a salt settling tank 2, an overflow tank 3, a circulating mother liquor tank 4, a filtering device 5 and a causticizing system 6, in the alumina production process The discharge pipe of the evaporation station is connected with the strong alkali storage tank 2 and the circulating mother liquor tank 5 respectively; The upper part of the salt settling tank 2 is provided with an overflow pipe 7, and the bottom is provided with an underflow outlet 8. The overflow pipe 7 communicates with the overflow tank 3, and the underflow outlet 8 passes through the filter device 5 and communicates with the To the causticizing system 6; the outlet of the overflow tank 3 communicates with the circulating mother liquor tank 4 through a pump and a pipeline.

[0024] The salt discharge method of the Bayer process alumina production process of the presen...

Embodiment 2

[0036] The salt discharge system of the Bayer method alumina production process of the present invention comprises a strong alkali storage tank 1, a salt settling tank 2, an overflow tank 3, a circulating mother liquor tank 4, a filtering device 5 and a causticizing system 6, in the alumina production process The discharge pipe of the evaporation station is connected with the strong alkali storage tank 2 and the circulating mother liquor tank 5 respectively; The upper part of the salt settling tank 2 is provided with an overflow pipe 7, and the bottom is provided with an underflow outlet 8. The overflow pipe 7 communicates with the overflow tank 3, and the underflow outlet 8 passes through the filter device 5 and communicates with the To the causticizing system 6; the discharge port of the overflow tank 3 communicates with the circulating mother liquor tank 4 through a pump and a pipeline.

[0037] The salt discharge method of the Bayer process alumina production process of th...

Embodiment 3

[0049] Contrast test: compare the salt removal effects before and after using the salt removal method of the present invention.

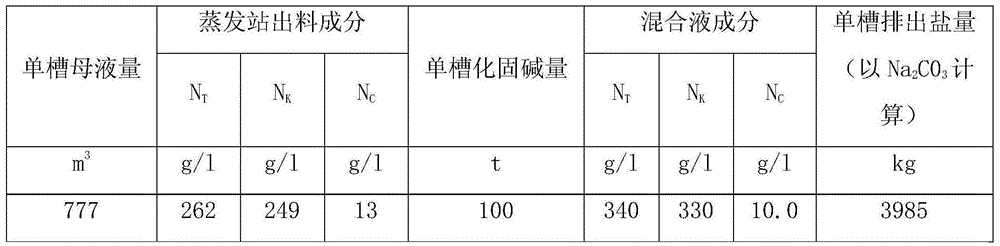

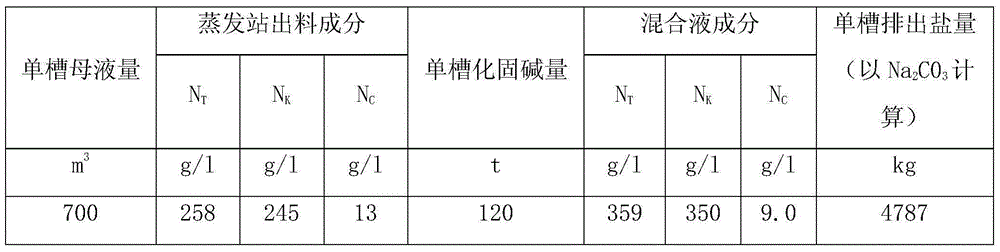

[0050] Before the test, the evaporation workshop used forced heating to increase the concentration of the sodium aluminate solution to crystallize the carbonate in the solution; during the test, the evaporation workshop used the mother liquor discharged from the evaporation station as the solution to dissolve the solid sodium hydroxide, and the dissolved The mixed solution (Nk concentration ≥ 320g / l, t ≥ 90°C) is sent to the third-stage salt settling tank for sedimentation and separation, the underflow salt filter is sent to the salt discharge operation, and the overflow is returned to the mother liquor tank as a strong alkali solution for deployment. During the test period, the four-stage coercion was stopped, and the mixed solution and the three-stage coercive output entered the third-stage salt settlement tank together. The whole test lasted 20 da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com