A kind of preparation method of stable sodium metaaluminate solution

A sodium metaaluminate and solution technology, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the problems of poor stability of sodium metaaluminate solution, and achieve the advantages of heat dissipation, good stability, Add less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of preparation method of stable sodium metaaluminate solution is realized by following process:

[0022] (1) Dissolve 220g of sodium hydroxide in 422g of demineralized water to prepare a sodium hydroxide solution, and add it to a three-necked flask with a reflux device, start stirring, and adjust the stirring speed to 110r / min. And within 1h, the sodium hydroxide solution was heated to 90°C.

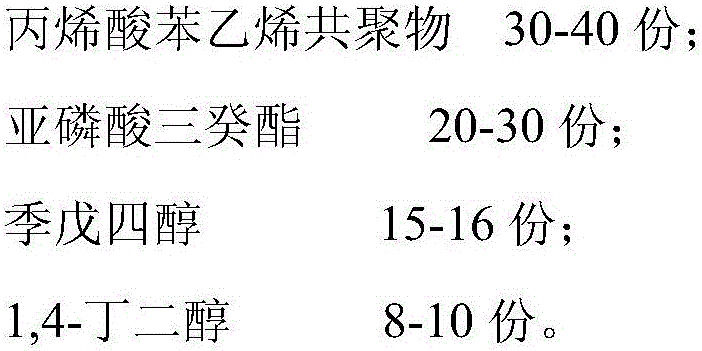

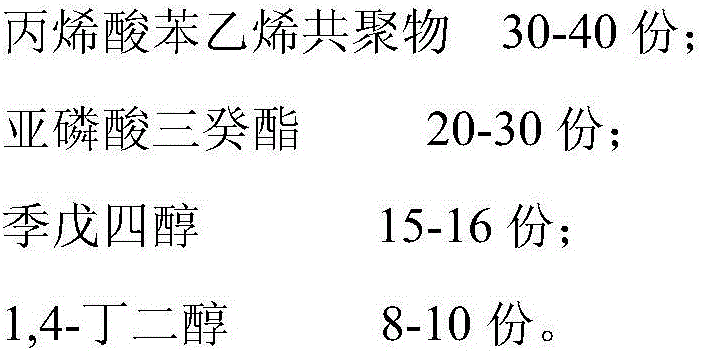

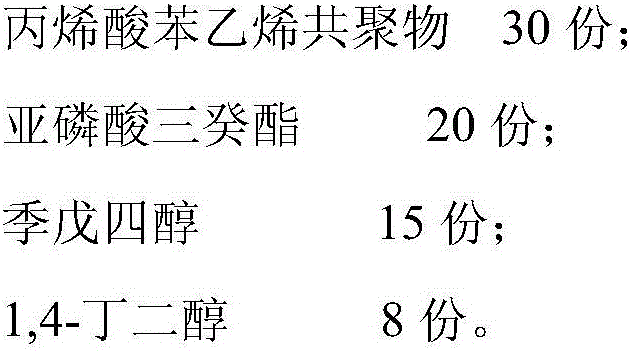

[0023] (2) Add 350g of aluminum hydroxide and adjust the stirring speed to 40r / min until the aluminum hydroxide is completely dissolved and the solution is clear; then within 0.5h, gradually heat up to 90°C and keep it warm for about 2 hours, then add 0.5wt% The stabilizer was stirred evenly at a speed of 20r / min to obtain sodium metaaluminate.

[0024] (3) A plate and frame filter press is used for press filtration, and the temperature of the finished product should not be too high during press filtration, and should be controlled at 40°C;

[0025] (4) Decolorize the abo...

Embodiment 2

[0030] A kind of preparation method of stable sodium metaaluminate solution is realized by following process:

[0031] (1) Dissolve 225g of sodium hydroxide in 430g of demineralized water to prepare a sodium hydroxide solution, and add it to a three-necked flask with a reflux device, start stirring, and adjust the stirring speed to 115r / min. And within 1-2h, the sodium hydroxide solution was heated to 90-180°C.

[0032] (2) Add 355g of aluminum hydroxide, adjust the stirring speed to 50r / min until the aluminum hydroxide is completely dissolved and the solution is clear; then within 0.8h, gradually heat up to 150°C and keep it warm for about 8 hours, then add 1wt% of Stabilizer, after stirring evenly at a speed of 25r / min, sodium metaaluminate was obtained.

[0033] (3) A plate and frame filter press is used for press filtration, and the temperature of the finished product should not be too high during press filtration, and should be controlled at 50°C;

[0034] (4) Decoloriz...

Embodiment 3

[0039] A kind of preparation method of stable sodium metaaluminate solution is realized by following process:

[0040] (1) Dissolve 230g of sodium hydroxide in 436g of demineralized water to prepare a sodium hydroxide solution, and add it to a three-necked flask with a reflux device, start stirring, and adjust the stirring speed to 120r / min. And within 2h, the sodium hydroxide solution was heated to 180°C.

[0041] (2) Add 360g of aluminum hydroxide, adjust the stirring speed to 60r / min, until the aluminum hydroxide is completely dissolved, and the solution is clear; then within 1h, gradually raise the temperature to 160°C, keep it warm for about 10 hours, and then add 2wt% of stable agent, after stirring evenly at a speed of 30r / min, sodium metaaluminate was obtained.

[0042] (3) A plate and frame filter press is used for press filtration, and the temperature of the finished product should not be too high during press filtration, and should be controlled at 70°C;

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com