Superfluid self-compacting concrete and preparing method thereof

A technology of self-compacting concrete and superfluidity, which is applied in the field of building materials to achieve the effects of good fluidity and self-compacting, low price, and simple and controllable methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Correspondingly, the embodiment of the present invention also provides a method for preparing superfluid self-compacting concrete, comprising the following steps:

[0039] S01. take each component by the formula of above-mentioned superfluid self-compacting concrete;

[0040] S02. Copper-plated steel fiber, cement, silicon powder, fly ash, mineral powder, limestone powder, and river sand are mixed to form a mixed material;

[0041] S03. Add high-efficiency water reducer and water to the above mixed material in sequence, carry out further mixing treatment, and then add sodium carbonate powder for mixing.

[0042] Specifically, the formulation of the superfluid self-compacting concrete and the preferred content and types of each component in the formulation are as described above, and will not be repeated here to save space.

[0043] In the above step S02, the method of mixing copper-plated steel fiber, cement, silica powder, fly ash, mineral powder, limestone powder, an...

Embodiment 1

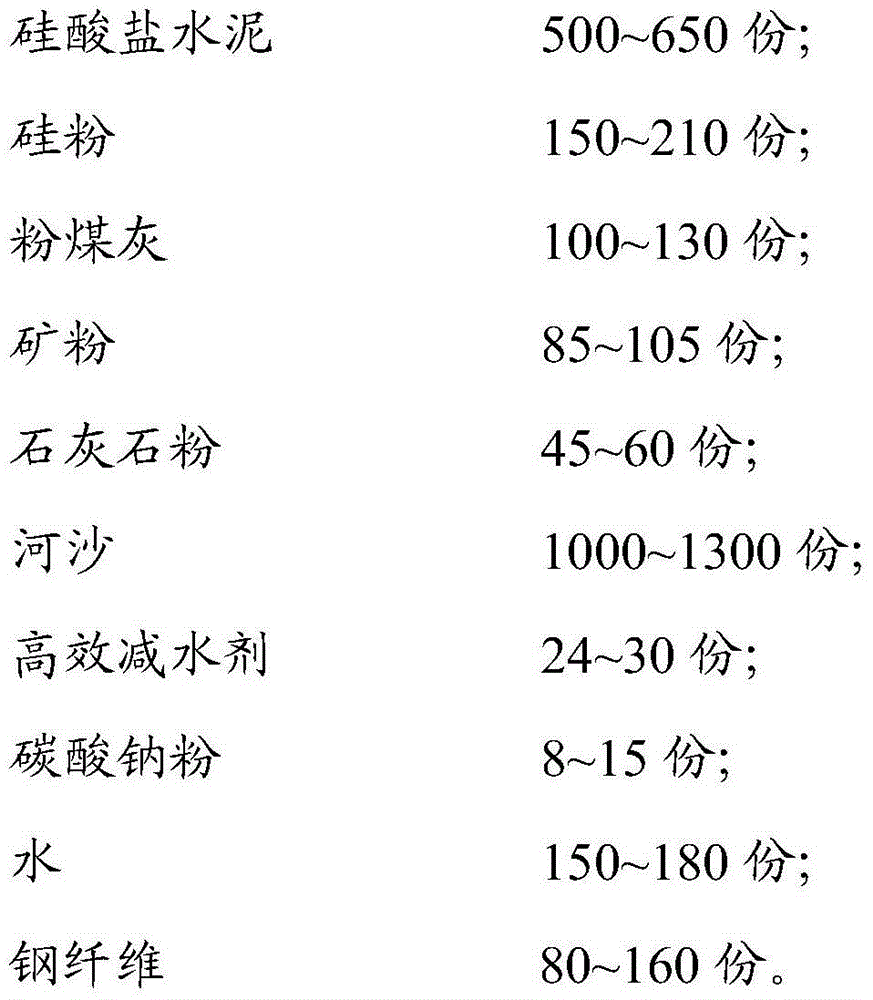

[0049] A superfluid self-compacting concrete, comprising the following formulation components in the following parts by weight:

[0050]

[0051] Wherein, the Portland cement is 52.5 grade Portland cement with a particle size of 30-60 μm; the particle size of the silica fume is 0.15 μm, wherein SiO 2 The mass percentage content is more than 85%; the fly ash is Class II fly ash with a particle size of 10-30 μm; the mineral powder is S95 or above mineral powder with a particle size of 10-30 μm; the limestone The particle size of the powder is 30-60 μm; the particle size of the river sand is 0.16-4.75 mm; the steel fiber is copper-plated ultra-fine steel fiber with a diameter of 0.13-0.20 mm and a length of 6-18 mm.

[0052] The preparation method of the above-mentioned superfluid self-compacting concrete comprises the following steps:

[0053] S11. Weigh each component according to the formula of the above-mentioned superfluid self-compacting concrete;

[0054] S12. Add cop...

Embodiment 2

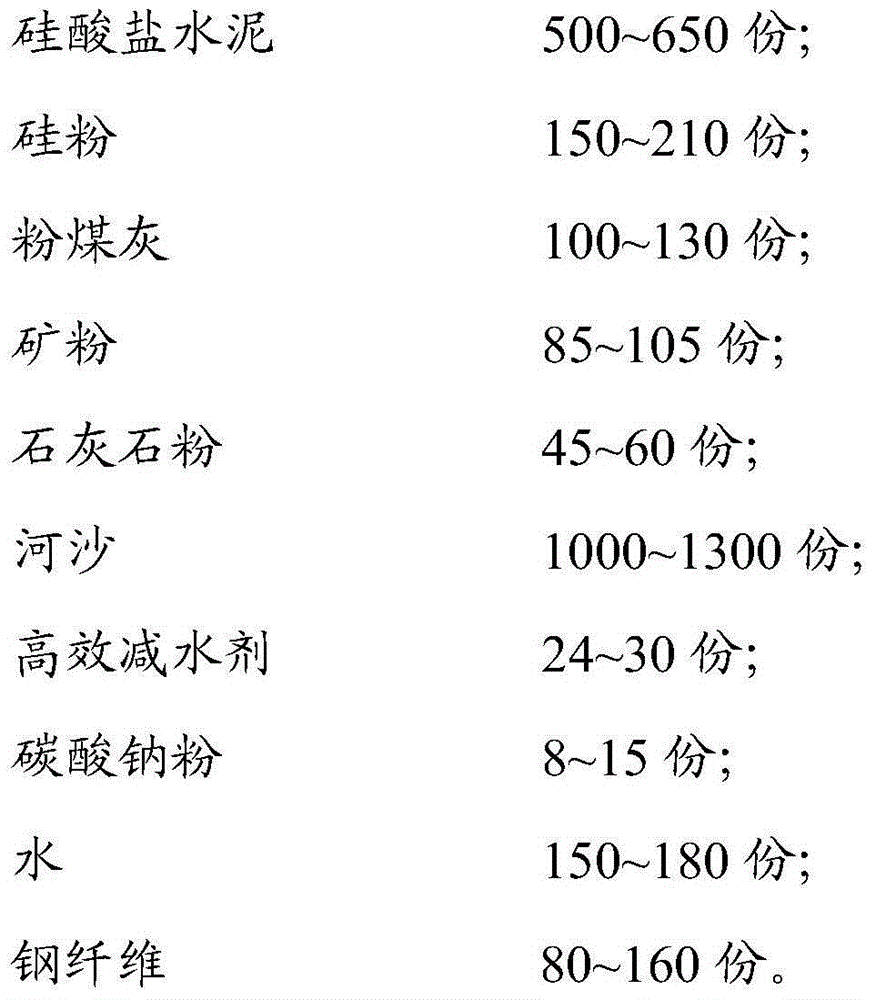

[0058] A superfluid self-compacting concrete, comprising the following formulation components in the following parts by weight:

[0059]

[0060] Wherein, the Portland cement is 52.5 grade Portland cement with a particle size of 30-60 μm; the particle size of the silica fume is 0.15 μm, wherein SiO 2 The mass percentage content is more than 85%; the fly ash is Class II fly ash with a particle size of 10-30 μm; the mineral powder is S95 or above mineral powder with a particle size of 10-30 μm; the limestone The particle size of the powder is 30-60 μm; the particle size of the river sand is 0.16-4.75 mm; the steel fiber is copper-plated ultra-fine steel fiber with a diameter of 0.13-0.20 mm and a length of 6-18 mm.

[0061] The preparation method of the above-mentioned superfluid self-compacting concrete comprises the following steps:

[0062] S21. take each component by the formula of above-mentioned superfluid self-compacting concrete;

[0063] S22. Add copper-plated stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Bending resistance | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com