Low-solid-phase low-temperature polymer drilling fluid

A polymer and low-solid phase technology, applied in the field of drilling fluid, can solve the problems that the rheological properties of drilling fluid vary greatly with temperature, cannot adapt well to low-temperature environment, and cannot guarantee rheological properties, etc., and achieve good low-temperature rheological stability properties, improving low temperature rheological properties, and meeting performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

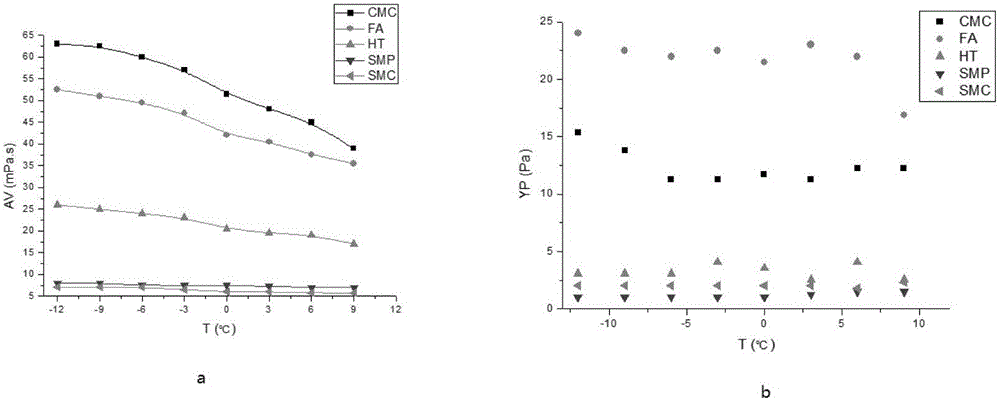

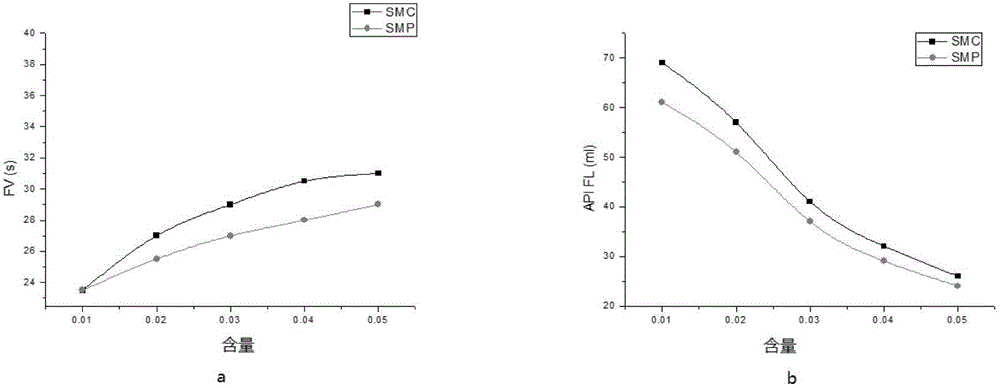

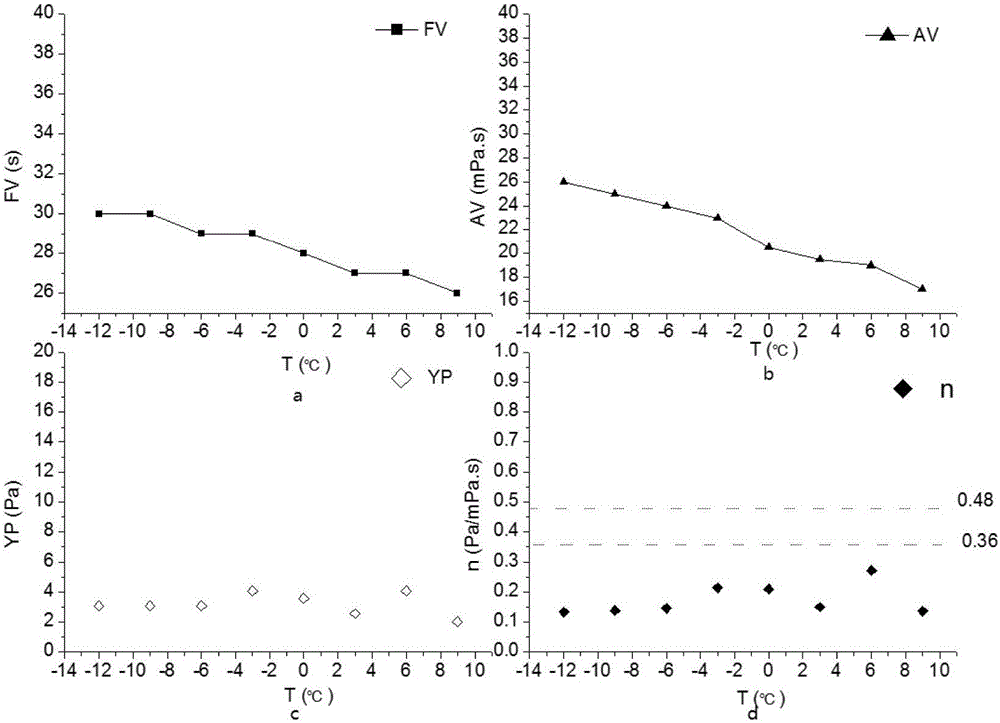

[0025] In order to illustrate the performance of the drilling fluid of the present invention, the applicant compares the performance of the drilling fluid of the present invention and the performance of drilling fluids with other compositions in the following examples.

[0026] In the following tests, the following materials were used: sodium bentonite, sodium hydroxide (NaOH), sodium chloride (NaCl), HT-101 (hereinafter referred to as HT, is a kind of amphoteric composite ionic multicomponent copolymer, which is a non-tackifying Type, product of Chengdu Shundali Company), FA-367 (hereinafter referred to as FA, is a water-soluble zwitterionic polymer, its relative molecular mass is 1 million-2.5 million, viscosity-increasing type, product of Chengdu Shundali Company), Carboxymethyl cellulose (CMC) selects low viscosity type (LV-CMC, the degree of polymerization is about 500), xanthan gum (XC), sulfonated lignite (SMC) and sulfonated phenolic resin (SMP).

[0027] In the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com