A static tubular alkylation reaction device and liquid acid-catalyzed alkylation reaction method

A technology of alkylation reaction and reaction device, which is applied in the production of liquid hydrocarbon mixtures and the petroleum industry, etc., can solve the problems of insufficient compact structure, unsatisfactory mixing, and huge equipment, and achieve simple structure, improved microscopic mixing level, The effect of small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

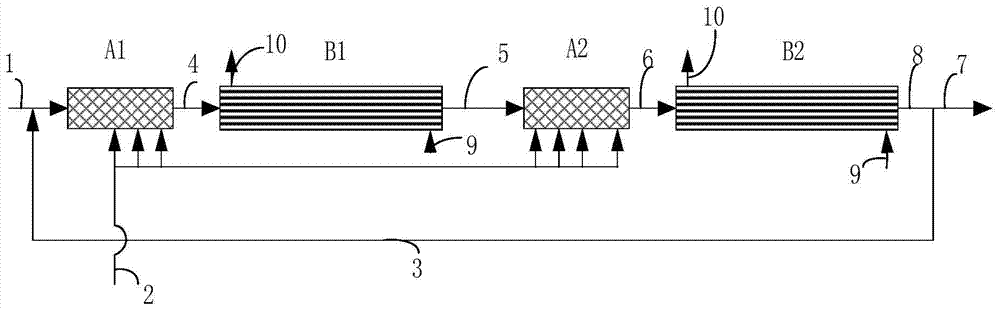

[0043] Such as figure 1 As shown, the catalyst concentrated sulfuric acid and C4 liquefied gas are injected into the mixing reaction section A1 (SMX type static mixer) of the first group of reactors through the circulating emulsion pump for pre-mixing, and the acid-hydrocarbon volume ratio of the acid-hydrocarbon emulsion is 1:1 . The mixed emulsion flows through the whole reactor, so that the acid hydrocarbon emulsion is completely mixed for a period of time in circulation; another stream of C4 liquefied gas reaction materials with a prepared alkanes molar ratio of 8.5:1 enters the front of A1 vertically (two feeds Port) and the mixing reaction section A2 of the second group of reactors, the olefins are strongly mixed with the circulating acid emulsion in A1, and the discharged mixed material enters B1 (the filler used is wire mesh corrugated filler, stainless steel with a wire diameter of 0.15mm Silk), further mixing reaction to take heat, the temperature of the whole react...

Embodiment 2

[0046] Such as figure 1 As shown, the alkylation catalyst is strongly acidic AlCl 3Type ionic liquid and C4 liquefied gas are pumped into the mixing reaction section A1 (SK static mixer) of the first group of reactors through the circulating emulsion pump for pre-mixing, and the acid-hydrocarbon volume ratio of the acid-hydrocarbon emulsion is 1.2:1.0. The mixed emulsion flows through the entire reactor, so that the acid hydrocarbon emulsion is completely mixed for a period of time; another C4 liquefied gas reaction material with a molar ratio of alkanes of 6.0:1 enters A1 and A2 (SK static mixer) vertically ), the olefins are strongly mixed with the circulating acid emulsion in A1, and the discharged mixed material enters B1 (the packing used is Pall ring packing, the specification ¢3.0×3.0) for further mixing and reaction to obtain heat, and the temperature of the entire reaction section is controlled at -3 ℃. The incompletely reacted material from B1 enters the second gro...

Embodiment 3

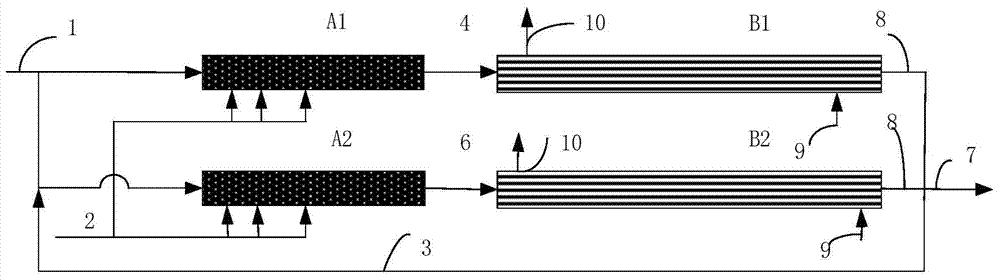

[0049] Such as figure 2 shown. Alkylation catalyst Concentrated sulfuric acid and C4 liquefied petroleum gas are injected into the mixing reaction section A (SL type static mixer) of each group of parallel reactors through the circulating emulsion pump for pre-mixing, and the acid-hydrocarbon volume ratio of the acid-hydrocarbon emulsion is 1.2 : 1.0. The mixed emulsion flows through the whole reactor, so that the acid hydrocarbon emulsion is completely mixed for a period of time; the prepared C4 liquefied gas reaction material with alkene molar ratio of 9.5:1 enters the mixing reaction section A1 of each group of reactors vertically In the front part and the whole section of A2, the olefins are strongly mixed with the circulating acid emulsion in A1 and A2, and the discharged mixed material enters B1 and B2 respectively (both use corrugated plate structured packing with a porosity of 60-70%). The mixed reaction takes heat, and the temperature of each group of reactors is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com