A liquid acid alkylation reactor and its application method

An alkylation reaction and liquid acid technology, applied in the field of reactors and alkylation reaction reactors, can solve the problems of large equipment, not compact enough structure, unsatisfactory mixing, etc., and achieve less internal components and easy processing , Improve the effect of micro-mixing level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

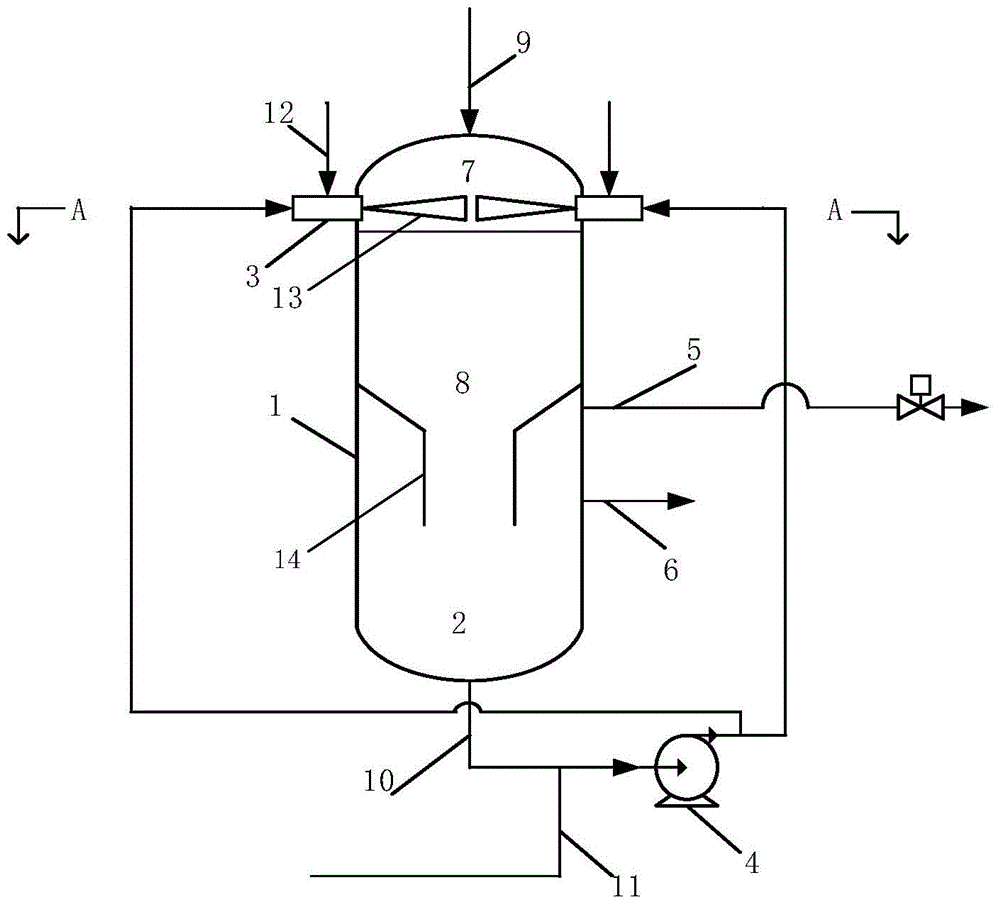

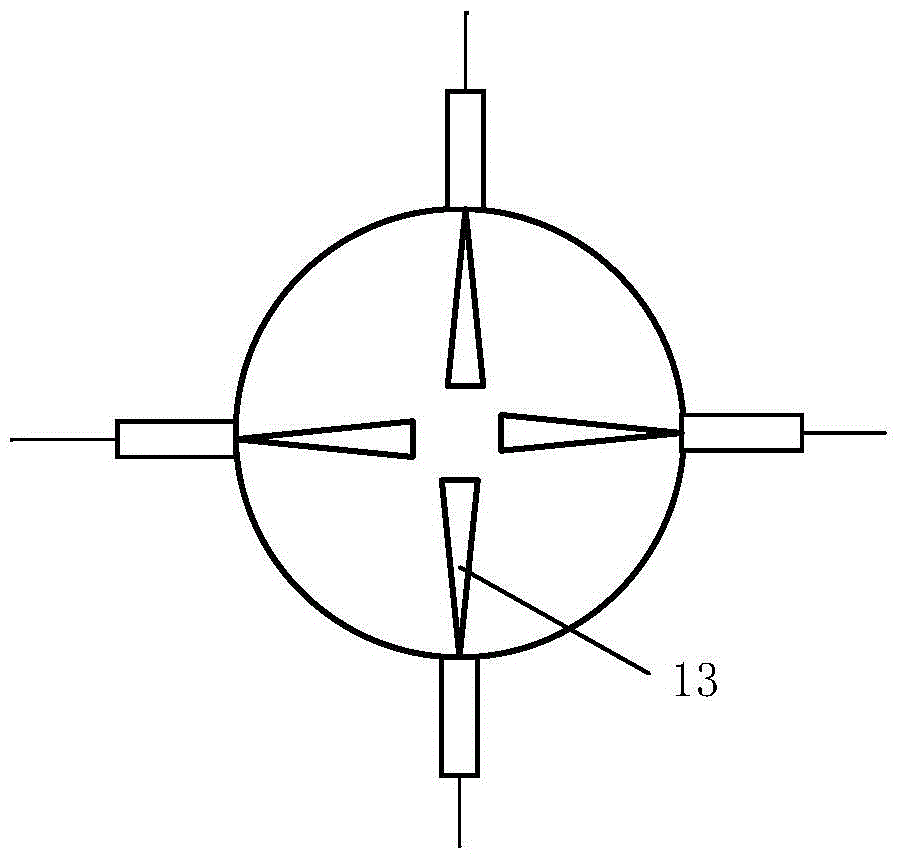

[0047] The structure of the liquid acid alkylation reactor is as attached figure 1 As shown, the diameter of the reactor is 2m, the height is 15m, the height of the mixing zone is 2m, two sets of jet mixers are arranged in the mixing zone, the position of the gas outlet is 5m from the bottom of the reactor, and the position of the liquid phase product outlet is At 1.5 m from the bottom of the reactor, the height of the conical draft tube is at 6.5 m from the bottom of the reactor.

[0048] The above-mentioned liquid acid alkylation reactor was used for the alkylation reaction, and the reaction raw material was C4 liquefied gas, which was obtained from Shijiazhuang Oil Refining and Chemical Industry Co., Ltd. The mass percent composition is: 0.098% of propane, 39.36% of isobutane, 13.51% of n-butane, 1.39% of isobutene, 14.70% of 1-butene, 14.92% of cis-butene, 16.0% of trans-butene and 0.022% of pentane. The reaction feed with the ratio of alkanes to olefins is 8:1 with circu...

Embodiment 2

[0050] Adopt the liquid acid alkylation reactor in the embodiment 1 to carry out the alkylation reaction, the reaction process and the reaction raw materials are the same as the embodiment 1, the difference is that the liquid acid catalyst is 99.5% strongly acidic AlCl 3 Type ionic liquid (AlCl 3 :(C 2 h 5 ) 3 NHCl=0.67) (produced by Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences), the reaction raw material is C4 liquefied gas, and the source and composition are the same as in Example 1. The reaction feed with alkene ratio of 6:1 is formulated with isobutane, the reactor pressure is controlled at 0.25MPa, and the temperature is -3°C. The alkylation reaction product undergoes distillation to remove most of the carbon four components to obtain an alkylate oil. The dry point of the obtained alkylate oil is 189°C, the RON value is 96.2, and the MON value is 93.9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com