A liquid acid-catalyzed alkylation reaction method and device for isoparaffins and olefins

A technology of alkylation reaction and isoparaffin, applied in chemical instruments and methods, production of liquid hydrocarbon mixtures, organic chemistry, etc., can solve the problems of insufficient compact structure, unsatisfactory mixing, and large equipment, etc., to facilitate processing , Improve the level of micro-mixing, the effect of saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

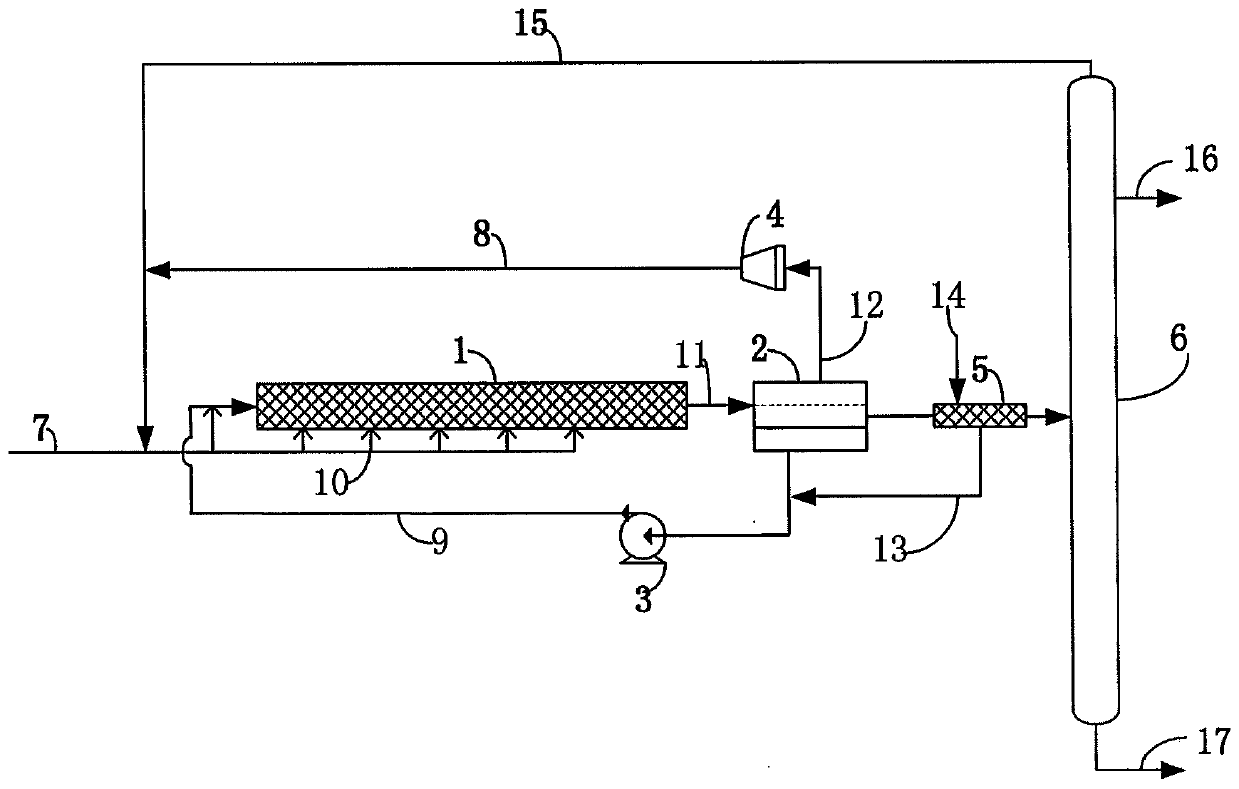

[0038] As shown in the figure, this embodiment provides a method and device using concentrated sulfuric acid as an alkylation catalyst.

[0039] Alkylation catalyst concentrated sulfuric acid (concentration is 98.5%, the same below) and circulating hydrocarbons are pumped into a group of static mixers 1 (Sulzer Engineering Machinery Manufacturing Co., Ltd. SMV TM type, the same below), the prepared alkylation reaction raw material with an alkene ratio of 8.0:1 enters the side part of the static mixer 1 vertically through the pipeline 10 (the raw material line is divided into 2 routes) and is pressurized by the circulation pump 3 The circulating acid emulsion in the acid hydrocarbon circulation line 9 undergoes strong mixing, so that the olefins in the mixed material reach a microscopic mixed state. The uniformly mixed mixed material reacts for a period of time and then enters the separator 2 under reduced pressure, and the partially vaporized isobutane in the separator evapora...

Embodiment 2

[0042] As shown in the figure, this embodiment provides a method and device using concentrated sulfuric acid as an alkylation catalyst.

[0043] Alkylation catalyst Concentrated sulfuric acid (98.5% concentration, the same below) and circulating hydrocarbons are pumped into the main channel of a set of static mixer 1 through circulation pump 3, and the prepared alkylation reaction raw materials have alkene ratio of 10.0:1 The side part of the static mixer 1 vertically enters the static mixer 1 through the pipeline 10 (the raw material line is divided into 4 routes), and the circulating acid emulsion in the acid hydrocarbon circulation pipeline 9 pressurized by the circulating pump 3 undergoes strong mixing action, so that the olefins in the mixed material reach a microscopic mixed state . The uniformly mixed mixed material reacts for a period of time and then enters the separator 2 under reduced pressure, and the partially vaporized isobutane in the separator evaporates to rem...

Embodiment 3

[0046] As shown in the figure, a kind of strongly acidic AlCl provided in this embodiment 3 A method and an apparatus for using an ionic liquid as an alkylation catalyst.

[0047] Alkylation Catalyst Strongly Acidic AlCl 3 Type ionic liquid (concentration is 95.0%, the same below) and circulating hydrocarbons are injected into the main channel of a group of static mixers 1 through circulating pump 3, and the prepared alkylation reaction raw materials with alkene ratio of 7.0:1 are passed through pipeline 10 (The raw material line is divided into 3 routes) The side part that vertically enters the static mixer 1 and the circulating acid emulsion of the acid hydrocarbon circulation line 9 pressurized by the circulating pump 3 have a strong mixing action, so that the olefins in the mixed material reach a microscopic mixing state. The uniformly mixed mixed material reacts for a period of time and then enters the separator 2 under reduced pressure, and the partially vaporized isobu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com