A comprehensive treatment method of red mud and titanium concentrate

A comprehensive treatment, titanium concentrate technology, applied in the field of metal smelting, can solve the problems of high unit cost, large acid consumption, less research, etc., to improve the rate of ball formation, reduce viscosity, and facilitate growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

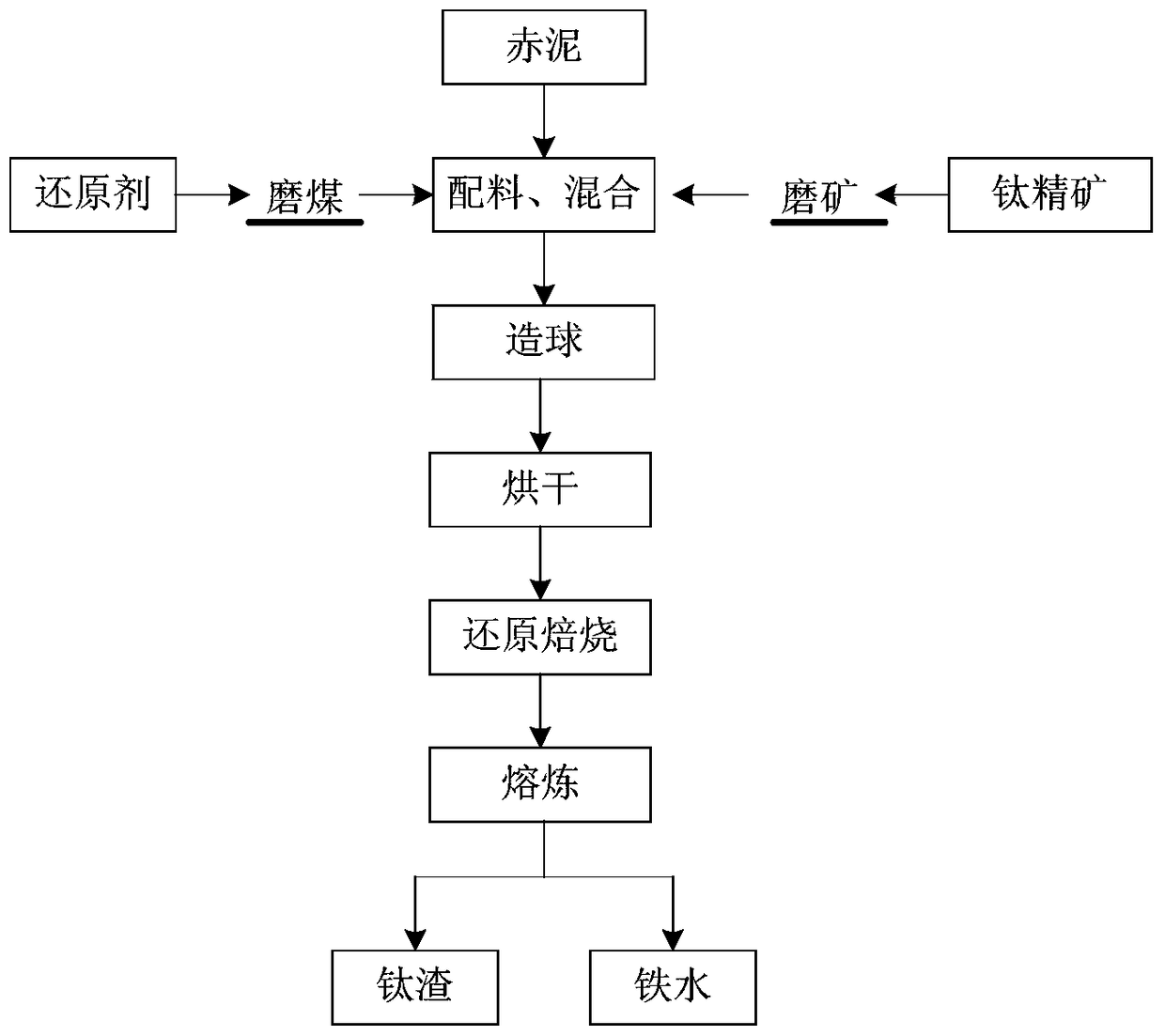

[0029] see process figure 1 . A method for adding titanium concentrate to co-produce molten iron and titanium slag in red mud, the method comprises mixing titanium concentrate and alumina red mud (TFe 38%, TiO 2 10.64%) were evenly mixed, and then added carbonaceous reducing agent anthracite for mixing and pelletizing, wherein the mass ratio of each component was: red mud: titanium concentrate: reducing agent = 100:24:15.8. The ball forming rate of the pelletizing process is 92%, and the falling strength of the pellets is 6-8 times.

[0030] The pellets made of the above raw materials are dried and roasted at a temperature of 1150-1300°C to obtain metallized pellets; then the metallized pellets are put into a smelting furnace and melted at 1500-1550°C to obtain good separation of slag and iron molten iron and titanium slag. In the obtained titanium slag, TiO2 is 45.3%, the recovery rate of TiO2 is 97.2%, and the recovery rate of iron is 96.23%.

Embodiment 2

[0032] A method for adding titanium concentrate to co-produce molten iron and titanium slag in red mud, the method is to add alumina red mud (TFe40%, TiO 2 9.78%) with 28% titanium concentrate. The mixed material is used as a new raw material, and then carbonaceous reducing agent coke powder is added for mixing and pelletizing. Calculated as a percentage of the raw ore, the proportion of the added reducing agent is about 14.8%. The ball forming rate in the pelletizing process is 95%, and the falling strength of the pellets is 10-12 times.

[0033] Dry the pellets made of the above raw materials for 2 hours, and then put them into a reduction furnace for direct reduction. The reduction temperature range is 1180-1320°C, and the total reduction time is 48 minutes. Then the metallized pellets are placed in a smelting furnace and melted at 1500-1600° C. to obtain molten iron and titanium slag with good separation of slag and iron. In the obtained titanium slag, TiO 2 47.63%, Ti...

Embodiment 3

[0035] A method for adding titanium concentrate to co-produce molten iron and titanium slag in red mud, the method is to add alumina red mud (TFe40%, TiO 2 8.64%) with 35% titanium concentrate. The mixed material is used as a new raw material, and then carbonaceous reducing agent is added for mixing and pelletizing. Calculated as a percentage of raw ore, the proportion of the added reducing agent is about 13.5%. The pelletizing rate in the pelletizing process is 90%, and the pelletizing strength is 5-6 times.

[0036] The pellets made of the above raw materials are dried at 180°C, and then the metallized pellets are put into a smelting furnace and melted at 1500-1650°C to obtain molten iron and titanium slag with good separation of slag and iron. In the obtained titanium slag, TiO 2 48.6%, TiO 2 The recovery rate was 98.1%, and the iron recovery rate was 96.72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com