High-performance copper chromium contactor material and preparing method thereof

A copper-chromium contact, high-performance technology, applied in the field of high-performance copper-chromium contact material and its preparation, can solve the problems of large outgassing, poor electrical and thermal conductivity, etc., and achieve the effects of energy saving and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

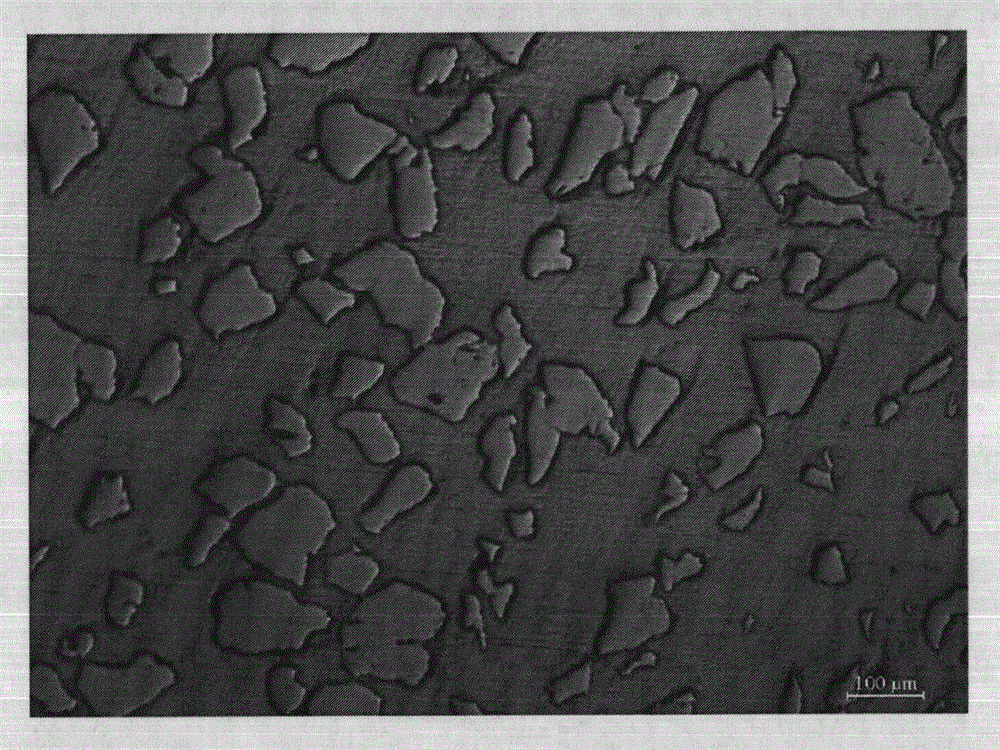

Embodiment 1

[0039] A high-performance copper chromium CuCr25 contact material is composed of the following components by weight: Cr is about 25%, and the balance is Cu; the raw materials are respectively 50-300 micron Cr powder and 300 micron Cu powder. The chromium powder is electrolytic chromium powder or thermite reduced chromium powder, and the copper powder is electrolytic copper powder or atomized copper powder. The purity of the chromium powder is 99.3%-99.98%.

[0040] The preparation method of described high-performance copper chromium CuCr25 contact material, comprises the following steps:

[0041] (1) Raw material selection

[0042] Select 50-300 micron electrolytic chromium powder or thermite reduced chromium powder and electrolytic copper powder or atomized copper powder below 300 microns;

[0043] (2) mixed powder

[0044] By Cu powder: the weight ratio of Cr powder is about 7.5: 2.5, and by the mixed powder of Cu powder and Cr powder: the weight ratio of copper ball=1: 1...

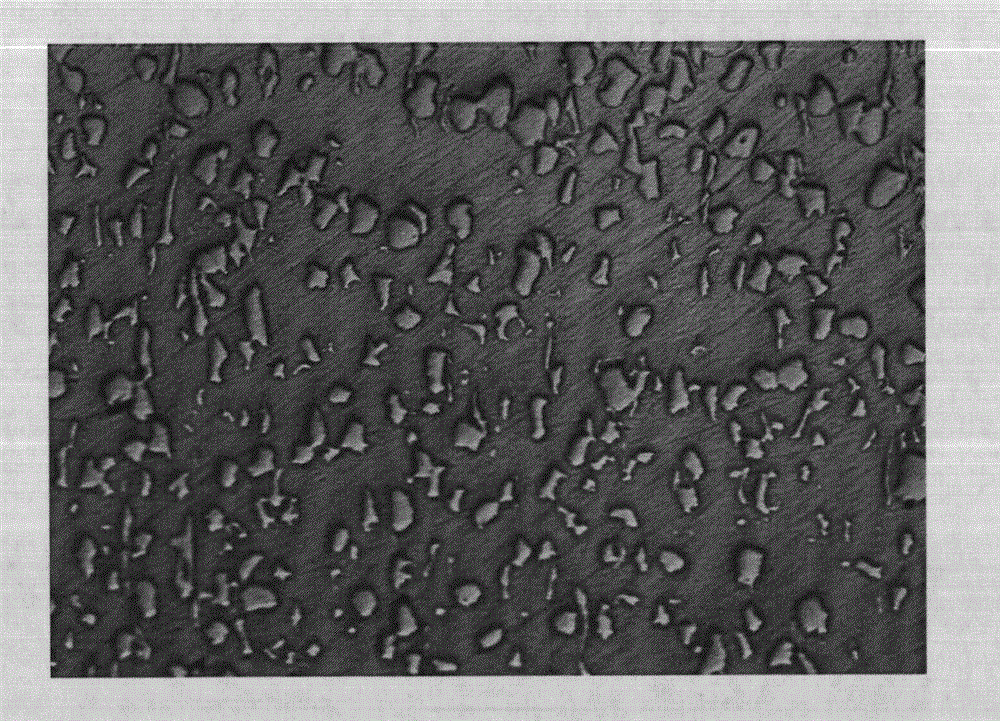

Embodiment 2

[0061] A high-performance copper chromium CuCr30 contact material is composed of the following components by weight: Cr is about 30%, and the balance is Cu; the raw materials are respectively 50-300 micron Cr powder and 300 micron Cu powder. The chromium powder is electrolytic chromium powder or thermite reduced chromium powder, and the copper powder is electrolytic copper powder or atomized copper powder. The purity of the chromium powder is 99.3%-99.98%.

[0062] The preparation method of described high-performance copper chromium CuCr30 contact material comprises the following steps:

[0063] (1) Raw material selection

[0064] Select 50-300 micron electrolytic chromium powder or thermite reduced chromium powder and electrolytic copper powder or atomized copper powder below 300 microns;

[0065] (2) mixed powder

[0066] By Cu powder: Cr powder is about 7: 3 weight ratio, and by the mixed powder of Cu powder and Cr powder: the weight ratio of copper ball=1: 1 carries out...

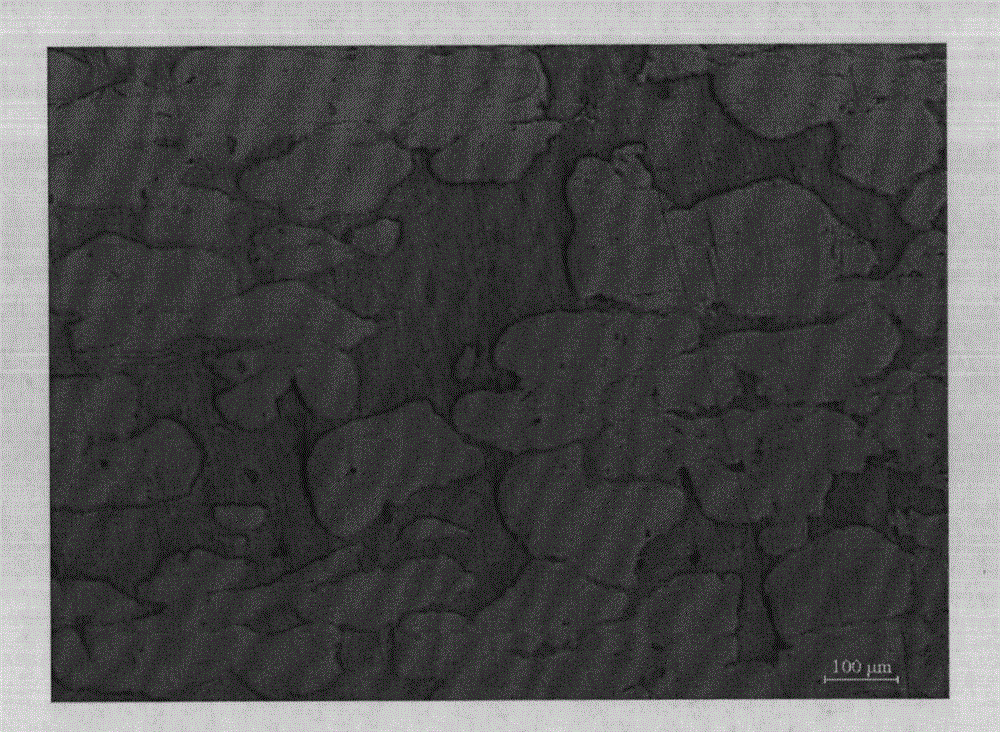

Embodiment 3

[0083] A high-performance copper chromium CuCr50 contact material is composed of the following components by weight percentage: Cr is about 50%, and the balance is Cu; the raw materials are Cr powder with a micron of 50-300 microns and Cu powder with a micron of less than 300 microns. The chromium powder is electrolytic chromium powder or thermite reduced chromium powder, and the copper powder is electrolytic copper powder or atomized copper powder. The purity of the chromium powder is 99.3%-99.98%.

[0084] The preparation method of described high-performance copper chromium CuCr50 contact material comprises the following steps:

[0085] (1) Raw material selection

[0086] Select 50-300 micron electrolytic chromium powder or thermite reduced chromium powder and electrolytic copper powder or atomized copper powder below 300 microns;

[0087] (2) mixed powder

[0088] By Cu powder: Cr powder is about 1: 1 weight ratio, and by the mixed powder of Cu powder and Cr powder: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com