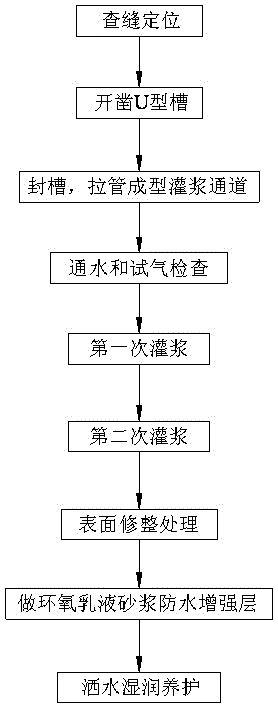

Construction treatment method for building cracks

A construction method and construction technology, which can be applied to buildings, building structures, artificial islands, etc., can solve the problems of difficulty in plugging construction, seepage through cracks in the floor structure, and affecting the integrity of the structure, so as to achieve simple and easy construction technology and construction. The effect of low comprehensive cost and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0083] Example 1: Project of District G of Wenhua Road Commercial Pedestrian Street in a certain city, with a total construction area of 85548m2 2 , two floors underground, seventeen floors above the ground, and the second floor below the basement has a construction area of 14,700m 2 , The thickness of the negative second floor floor is 250mm. After the completion of the main project, cracks and water seepage appeared in different degrees on the 250mm thick floor of the basement. According to statistics, the total length of cracks in the entire negative second floor floor is 6000m, and the daily water seepage is about 30t. After the demonstration of the main units of all parties, it was decided to use the above method to deal with the cracks in the bottom plate. The crack treatment of the bottom slab of the project started in early April 2014 and was completed in mid-May 2014. After the treatment, the basement slab no longer leaked, and the concrete structure slab surfac...

example 2

[0084] Example 2: Project of District D of Wenhua Road Commercial Pedestrian Street in a certain city, with a total construction area of 22866m2 2 , 23 floors above the ground, one floor underground, and the building area of the basement is 5350m2 2 , using a raft foundation, the thickness of the floor of the main building is 1m, and the thickness of the floor of the podium is 300mm. After the completion of the project, it was found that some water seepage cracks appeared on the 300mm thick bottom plate. According to the on-site statistics, the cracks were 580m long. After research by all parties, the main units decided to use the above method to treat the cracked part of the bottom plate of the project. After the treatment, the bottom plate no longer seeps , the surface of the structure is completely free of wet stains, and the water-stopping effect is good. The crack treatment of the bottom plate of the project started in early June 2014 and was completed in mid-June 20...

example 3

[0085] Example 3: Project of District A of Wenhua Road Commercial Pedestrian Street in a certain city, with a total construction area of 36,750m2 2 , one floor underground, twelve floors above the ground, using a raft foundation, the raft thickness of the main building part is 1m, and the floor thickness of the podium part is 300mm. The total length is 1800m according to the statistics. The main units of all parties decided to use the above method to treat the cracks in the bottom plate of the project. After the treatment, the bottom plate of the project has no leakage phenomenon, ensuring the normal use of the project. The project started in early July 2014 and was completed in late July 2014, saving a total of 417,800 yuan in construction costs. Saved 358,100 yuan in pumping costs during the use of the building.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com