Viscous damping wall

A viscous damping wall and viscous damping technology, applied in the field of viscous damping walls, can solve the problems that the shock absorption effect of the viscous damping wall cannot achieve the expected design effect, affect the energy consumption performance of the damping wall, and endanger the safety of buildings, etc. Achieve the effect of increasing the effective contact area, facilitating fabrication and connection, and ensuring out-of-plane stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

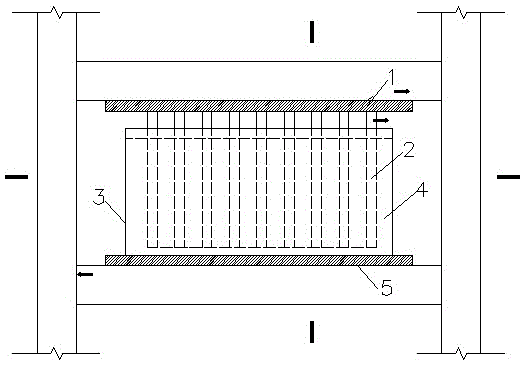

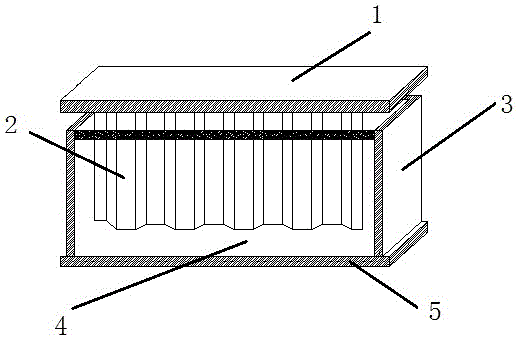

[0019] like figure 1 and figure 2 As shown, a viscous damping wall includes an upper connecting plate 1, an inner steel plate 2, an outer steel box 3, a viscous damping material 4 and a lower connecting plate 5; the inner steel plate 2 is fixed on the middle of the bottom surface of the upper connecting plate 1 , the outer steel box 3 is fixed on the lower connecting plate 5, the outer steel box 3 is filled with a viscous damping material 4, and the inner steel plate 2 is placed in the viscous damping material 4.

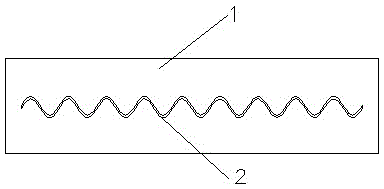

[0020] like Image 6 As shown, the inner steel plate 2 of the present embodiment adopts the curved corrugated mild steel, the height b is 400 mm, the width d is 800 mm, the thickness t is 5 mm, the half-wave amplitude H is 30 mm, and the wavelength is 200mm, the test piece with this parameter has good energy dissipation performance, and no damping hole is opened on the inner steel plate 2.

Embodiment 2

[0022] like image 3 and Figure 5 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the inner steel plate 2 of this embodiment is made of curved mild steel, and the inner steel plate 2 is provided with a damping hole 6, and the shape of the damping hole 6 is circular , the size and position of the damping hole 6 can be adjusted according to the engineering situation.

Embodiment 3

[0024] like Figure 4 and Figure 5 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the inner steel plate 2 of this embodiment adopts trapezoidal corrugated mild steel, and the damping hole 6 is provided on the inner steel plate 2, and the shape of the damping hole 6 is circular. The size and position of the damping hole 6 can be adjusted according to the engineering situation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com