Distributors for hollow bricks

A slurry distributor and brick technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of damage to the thermal insulation performance of walls, high requirements for personnel operations, and cumbersome processes, and meet the requirements of reducing proficiency , Realize mechanized operation and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

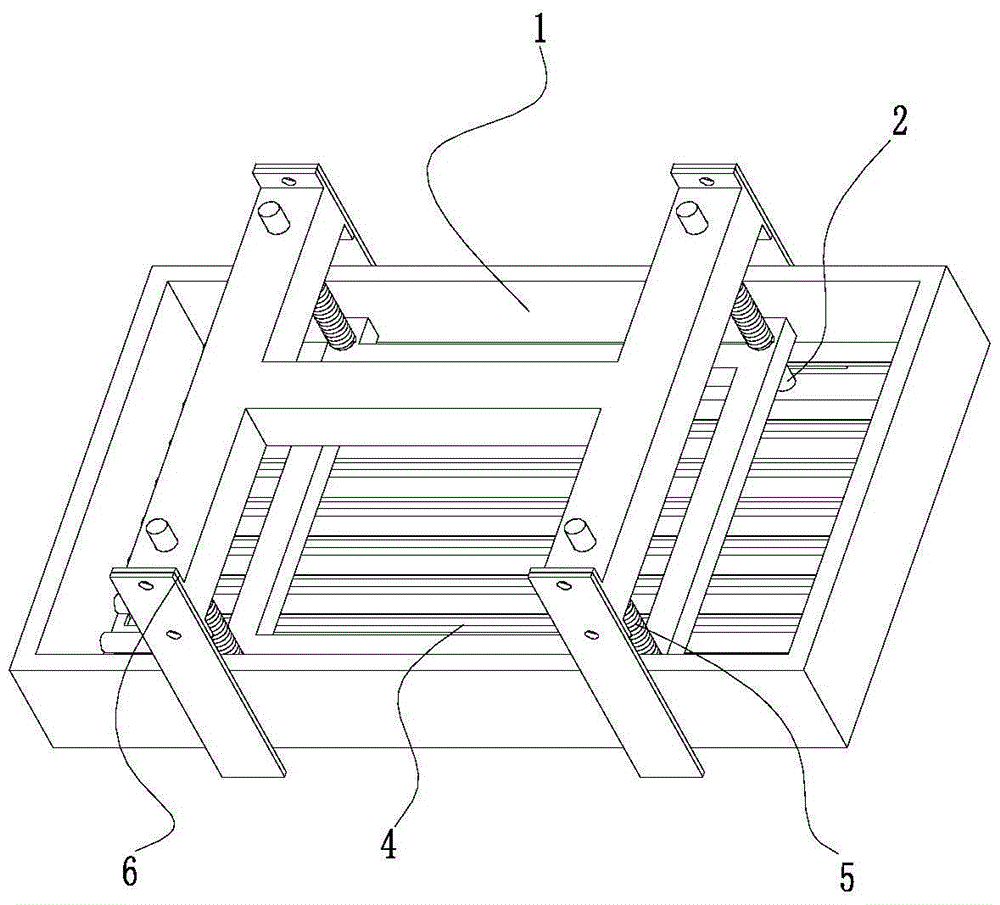

[0025] The grout distributing device that is used for hollow brick of the present embodiment, as figure 1 As shown, it includes the pulp box 1 and the support rod 2 that runs through the bottom plate of the pulp box 1, that is, the support rod 2 protrudes from the bottom plate of the pulp box 1 by a certain distance, and this distance is the thickness of the pulp. The pulp box 1 can move up and down along the support rod 2. The bottom plate of the pulp box 1 is provided with a number of strip-shaped through holes matching the bonding surface of the hollow bricks (covered by the retaining strip 4 in the figure, not shown). The rod 2 is fixed with a retaining bar 4 that can be used to close the strip-shaped through hole, and the retaining bar 4 is located above the bar-shaped through hole; a compressed return spring 5 is provided between the pulp box 1 and the support rod 2, and in the natural state, The retaining strip 4 is closely attached to the bottom plate of the pulp box 1...

Embodiment 2

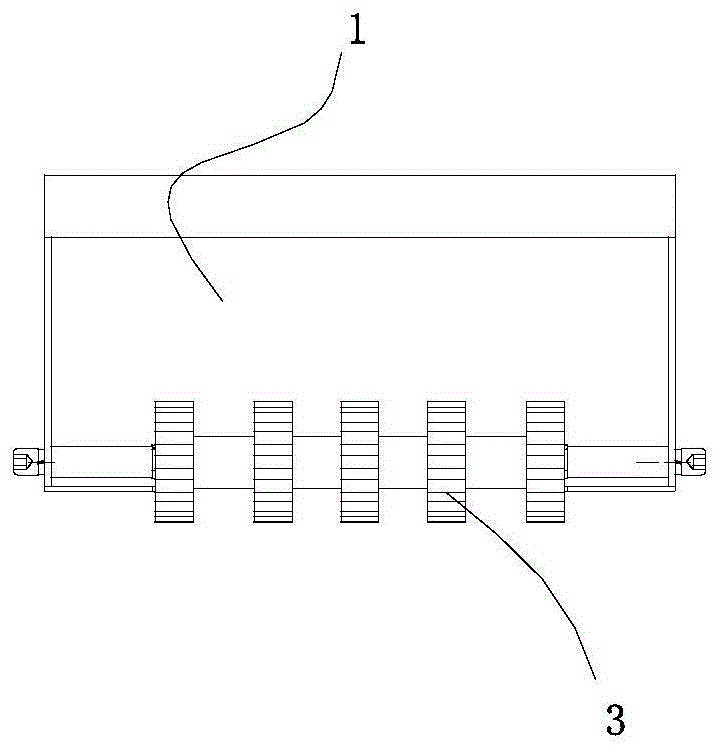

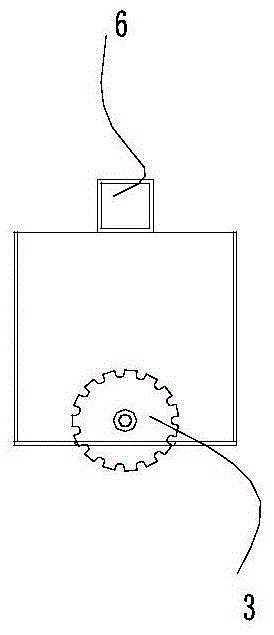

[0031] Such as figure 2 and image 3 As shown, the pulp distributor for hollow bricks in this embodiment includes a pulp box 1 and a plurality of strip-shaped through holes that match the bonding surface of the hollow bricks on the bottom plate of the pulp box 1, and the strip-shaped through holes There is a toothed roller 3 embedded in it, and the toothed roller 3 is close to the inner edge of the strip-shaped through hole; when distributing the slurry, the toothed roller 3 is pressed against the bonding surface of the hollow brick and rolled so that the mortar is covered with the hollow brick. The bonding surface, that is, the mortar is applied to the bonding surface of the hollow brick by the rolling of the toothed roller, which can ensure that the mortar will not leak into the hollow cavity of the block. In addition, the pulp box 1 is provided with a handle 6 to facilitate manual operation.

[0032] This embodiment can be improved as follows:

[0033]1) A limiting plat...

Embodiment 3

[0036] This embodiment is an improvement on the basis of Embodiment 2, and the difference from Embodiment 2 is that the slurry distributor of this embodiment is such as Figure 4 with Figure 5 As shown, the pulp box is divided into three, the pulp boxes on both sides are kept at the same height, the middle pulp box is higher than the pulp boxes on both sides, and the bottom plate of each pulp box is equipped with toothed rollers .

[0037] The slurry distributor of this embodiment is suitable for Image 6 The hollow block shown in the thermal insulation wall, according to this embodiment, the grout distributor of the present invention can be extended and applied to the grout distribution work of various special-shaped hollow blocks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com