Arrayed omnidirectional type horizontal shear modal magnetostrictive transducer

A horizontal shear, magnetostrictive technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, ultrasonic/sonic waves/infrasonic waves to generate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with drawings and embodiments.

[0033] Based on the magnetostrictive effect, an array type omnidirectional horizontal shear mode magnetostrictive sensor is designed, and the sensor is used to excite a SH with a single mode and a consistent circumferential direction on the aluminum plate. 0 Modal guided waves.

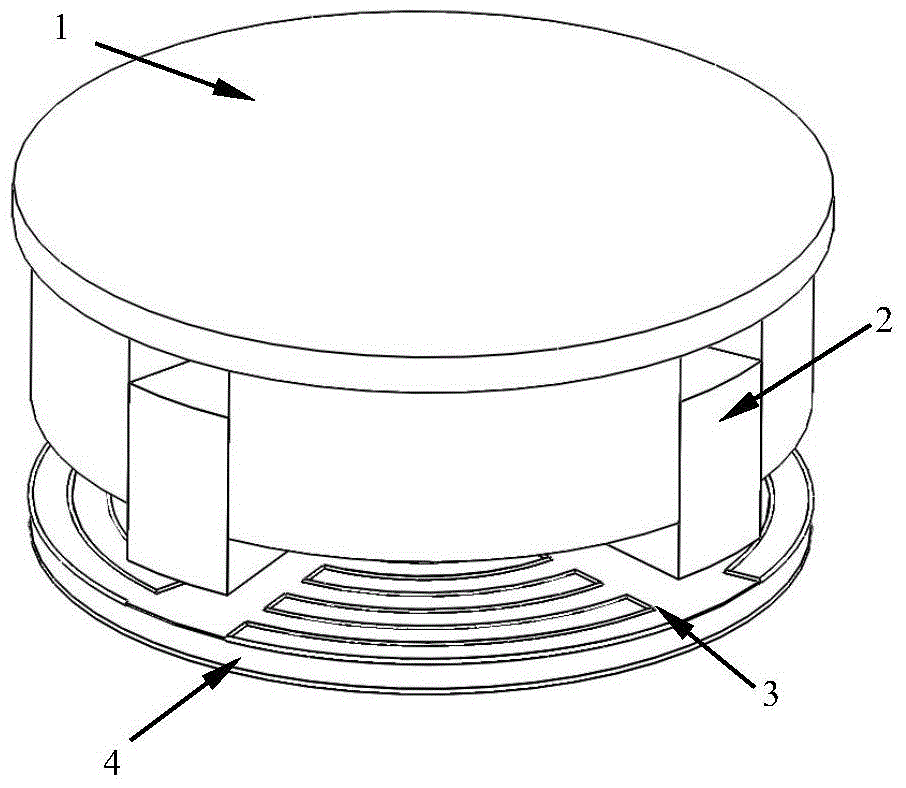

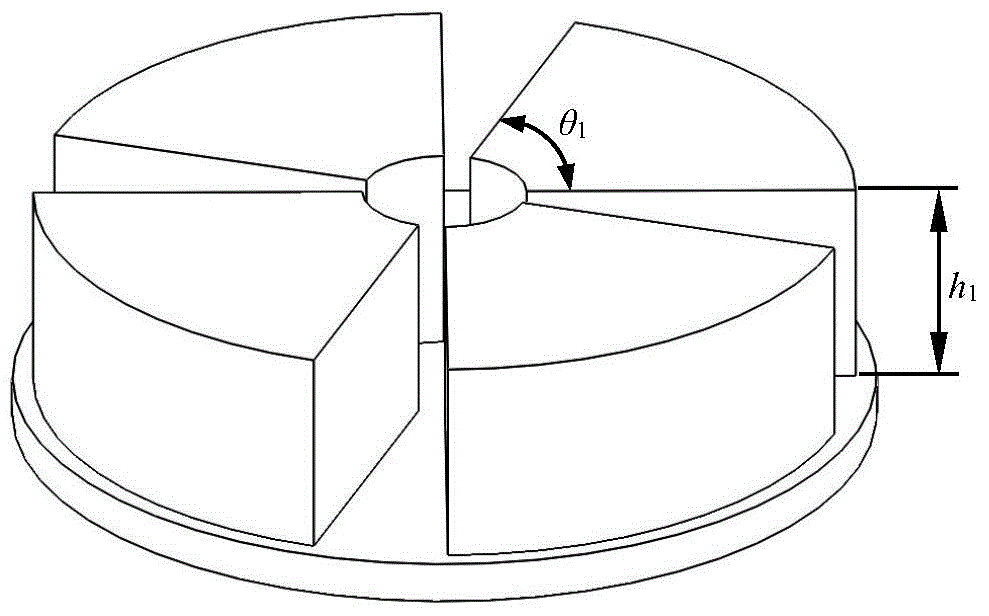

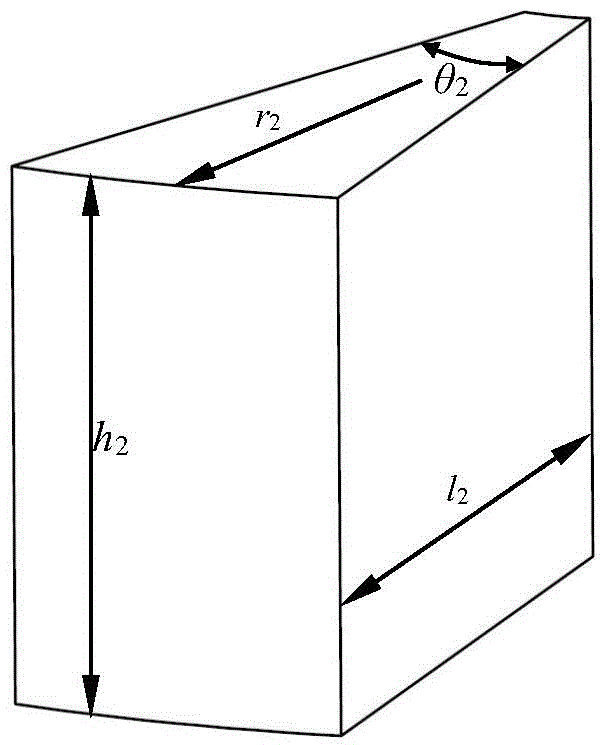

[0034] The structure diagram of the array omnidirectional horizontal shear mode magnetostrictive sensor is as follows: figure 1 As shown, it includes a support sleeve 1, a NdFeB magnet 2, a fan-shaped array-type folded coil 3 in a flexible circuit board, and a circular nickel sheet 4. The detection object is an aluminum plate with a specification of 1000×1000×1 (unit: mm). Figure 6.1-6.2 is the ultrasonic guided wave group velocity and phase velocity dispersion curve of the aluminum plate above. When the wavelength λ is determined, the frequency of the generated horizontal shear wave can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com